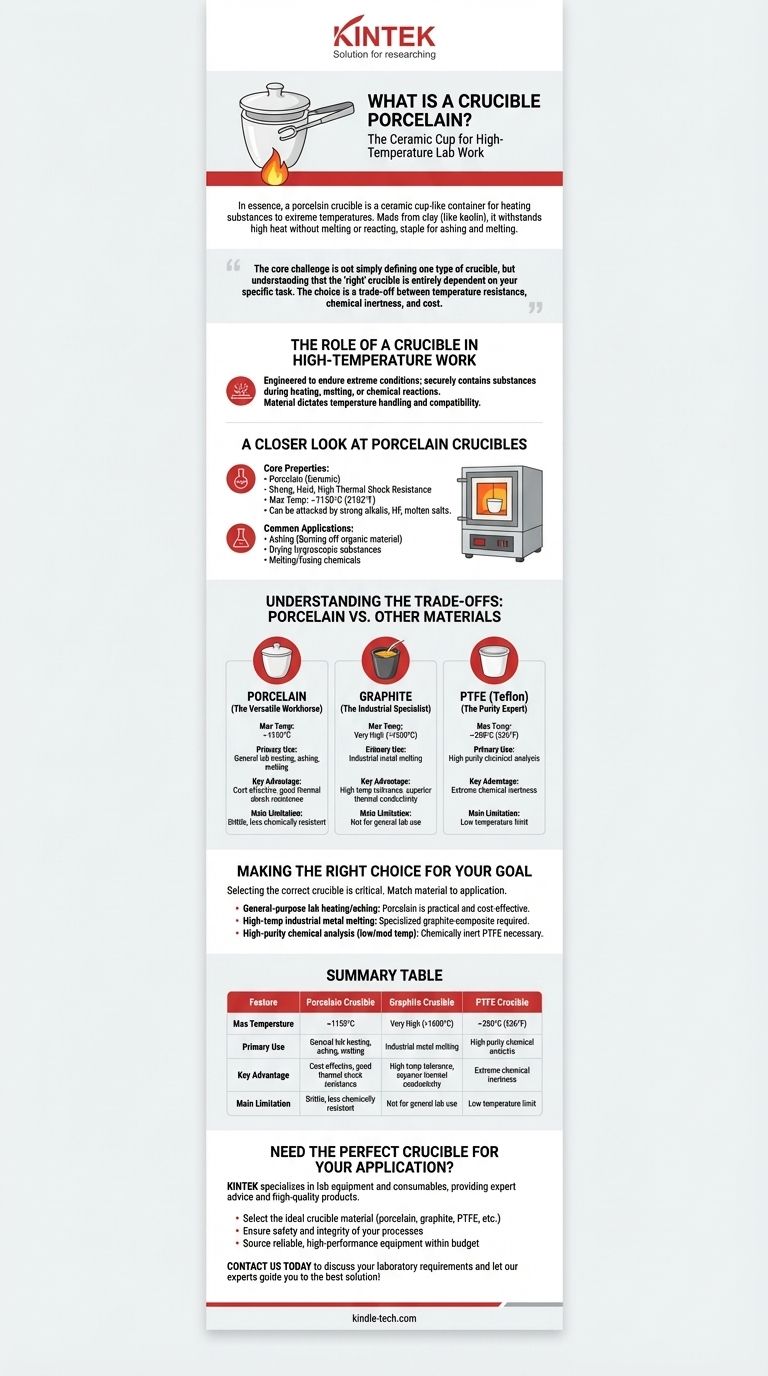

In essence, a porcelain crucible is a ceramic cup-like container used in laboratory settings for heating substances to very high temperatures. Made from a clay-based material like kaolin, it is designed to withstand extreme heat without melting or reacting with the contents, making it a staple for processes like ashing samples or melting chemical compounds.

The core challenge is not simply defining one type of crucible, but understanding that the "right" crucible is entirely dependent on your specific task. The choice is a trade-off between temperature resistance, chemical inertness, and cost.

The Role of a Crucible in High-Temperature Work

A crucible is a vessel engineered to endure extreme conditions that would destroy standard glassware. Its primary job is to securely contain a substance while it is being heated, melted, or undergoing a chemical reaction.

The material of the crucible is its most critical feature, as this dictates the temperatures it can handle and the substances it can safely hold.

A Closer Look at Porcelain Crucibles

Porcelain is one of the most common and traditional materials for laboratory crucibles, valued for its balance of performance and cost.

Core Properties

Porcelain is a type of ceramic known for its strength, hardness, and high resistance to thermal shock. It can typically withstand temperatures up to 1150°C (2102°F).

While generally inert, it can be attacked by strong alkaline substances, hydrofluoric acid, and molten salts at high temperatures.

Common Applications

You will most often find porcelain crucibles used for ashing—the process of burning off organic material to leave behind an inorganic residue for analysis.

They are also used for drying hygroscopic substances or melting and fusing various chemical compounds in a general laboratory setting.

Understanding the Trade-offs: Porcelain vs. Other Materials

Porcelain is a versatile workhorse, but specialized tasks demand specialized materials. Understanding its limitations in context is key to proper selection.

Porcelain vs. Graphite

Modern industrial crucibles, especially for metallurgy, are often graphite-based composites. These are engineered for much higher temperatures and the mechanical stress of holding tons of molten metal.

Graphite offers superior thermal conductivity, allowing for faster and more even heating, which is critical in furnace operations. Porcelain is not suitable for these demanding industrial applications.

Porcelain vs. PTFE (Teflon)

For high-purity chemical analysis at lower temperatures, a PTFE crucible is a better choice. PTFE is almost completely chemically inert, preventing any leaching or contamination of the sample.

However, its temperature limit is significantly lower, typically around 280°C (536°F). It is used when chemical purity is the absolute priority, not extreme heat.

Key Limitations of Porcelain

The primary limitation of a porcelain crucible is its brittleness; it can crack or shatter if dropped or subjected to sudden, extreme temperature changes beyond its rating.

It is also less chemically resistant than materials like PTFE, making it unsuitable for certain high-purity analytical work.

Making the Right Choice for Your Goal

Selecting the correct crucible is a critical decision that directly impacts the safety and success of your work. Base your choice on the specific demands of your application.

- If your primary focus is general-purpose lab heating or ashing samples: A porcelain crucible is almost always the most practical and cost-effective choice.

- If your primary focus is high-temperature industrial metal melting: A specialized graphite-composite crucible is required for its superior heat tolerance and mechanical strength.

- If your primary focus is high-purity chemical analysis at low-to-moderate temperatures: A chemically inert material like PTFE is necessary to prevent sample contamination.

By matching the material's properties to your objective, you ensure the integrity of your experiment and the reliability of your results.

Summary Table:

| Feature | Porcelain Crucible | Graphite Crucible | PTFE Crucible |

|---|---|---|---|

| Max Temperature | ~1150°C (2102°F) | Very High (>1600°C) | ~280°C (536°F) |

| Primary Use | General lab heating, ashing, melting | Industrial metal melting | High-purity chemical analysis |

| Key Advantage | Cost-effective, good thermal shock resistance | High temp tolerance, excellent thermal conductivity | Extreme chemical inertness |

| Main Limitation | Brittle, can react with strong alkalis | Not for general lab use | Low temperature limit |

Need the perfect crucible for your specific application?

Choosing the right lab equipment is critical for your results. KINTEK specializes in lab equipment and consumables, serving laboratory needs with expert advice and high-quality products.

We can help you:

- Select the ideal crucible material (porcelain, graphite, PTFE, and more) for your temperature and chemical requirements.

- Ensure the safety and integrity of your heating, ashing, or melting processes.

- Source reliable, high-performance equipment that fits your budget.

Contact us today via our [#ContactForm] to discuss your laboratory requirements and let our experts guide you to the best solution!

Visual Guide

Related Products

- Alumina Al2O3 Ceramic Crucible Semicircle Boat with Lid for Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Alumina Al2O3 Ceramic Crucible for Laboratory Muffle Furnace

- Engineering Advanced Fine Ceramics Alumina Crucibles (Al2O3) for Thermal Analysis TGA DTA

- Engineering Advanced Fine Ceramics Alumina Al2O3 Crucible With Lid Cylindrical Laboratory Crucible

- Arc-Shaped Alumina Ceramic Crucible High Temperature Resistant for Engineering Advanced Fine Ceramics

People Also Ask

- What are the functional advantages of using high-purity alumina crucibles? Achieve Precise Oxidation Data

- What is the function of alumina crucibles in Na3V2(PO4)2F3 synthesis? Ensure Purity in NVPF Production

- Why are high-purity alumina crucibles used for LATP? Preserve Purity and Conductivity in Sintering

- Why is a high-purity alumina crucible preferred for high-temperature oxidation? Ensure Unmatched Data Integrity

- What role do high-purity alumina crucibles play in high-temperature steam oxidation? Ensure Data Integrity up to 1350°C