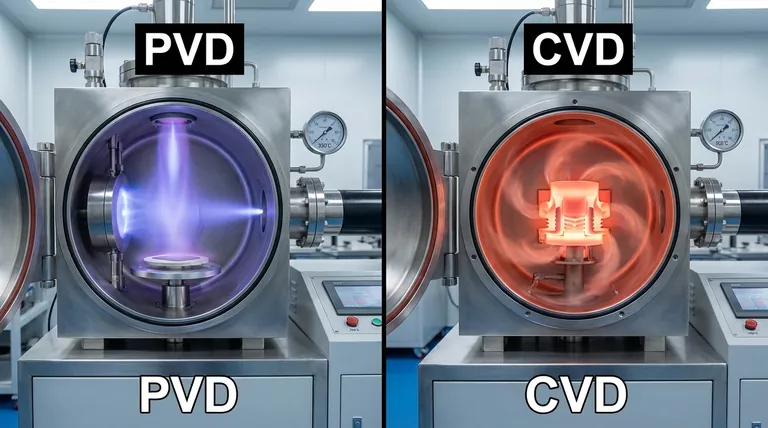

The fundamental difference between PVD and CVD is how the coating material is transferred to a part's surface. Physical Vapor Deposition (PVD) uses a physical process, like vaporizing a solid material, to deposit a thin film in a line-of-sight fashion. In contrast, Chemical Vapor Deposition (CVD) uses a chemical process where precursor gases react on the substrate's surface to form the coating.

Choosing between PVD and CVD isn't about finding a "better" technology, but about matching the unique characteristics of a physical process versus a chemical one to your specific material, part geometry, and desired outcome.

The Fundamental Process Distinction

To truly understand these technologies, you must first grasp their core mechanism. One is like spray painting with atoms, while the other is like baking a new layer onto a surface.

PVD: A Physical, Line-of-Sight Process

Physical Vapor Deposition is a "line-of-sight" process. A solid or liquid source material is converted into a vapor through physical means, such as heating or sputtering (bombarding it with ions).

This vapor then travels in a straight line through a vacuum chamber and condenses on the substrate, forming a thin, solid film. Because the atoms travel in a straight line, areas not directly exposed to the source are harder to coat uniformly.

CVD: A Chemical, Conformal Process

Chemical Vapor Deposition is a chemical process that relies on precursor gases. These gases are introduced into a reaction chamber containing the heated substrate.

A chemical reaction occurs on and near the hot surface, causing the gases to decompose and form a solid film on the substrate. This process is not line-of-sight, allowing the coating to form uniformly over complex shapes and even inside cavities, a property known as high conformality.

Key Technical Differences at a Glance

The core difference in process—physical versus chemical—creates several critical distinctions that directly impact which method is suitable for a given application.

Operating Temperature

PVD operates at relatively low temperatures, typically between 250°C and 450°C. This makes it suitable for coating materials that cannot withstand high heat, such as certain plastics or tempered steels.

CVD requires significantly higher temperatures, often ranging from 450°C to over 1050°C, to drive the necessary chemical reactions. This limits its use to substrates that can endure such extreme heat without damage or distortion.

Source Material

In PVD, the source material is a solid target of the exact material you wish to deposit. This offers straightforward control over the coating's composition.

In CVD, the source materials are volatile precursor gases. The final coating is a byproduct of the chemical reaction between these gases, which offers versatility but can add complexity.

Coating Coverage & Conformality

PVD is a line-of-sight impingement process. This can make it challenging to achieve a perfectly uniform coating on complex, three-dimensional parts without sophisticated part-rotation systems.

CVD is a multidirectional deposition process. Since the precursor gases envelop the entire part, it excels at providing highly uniform and conformal coatings on intricate geometries.

Resulting Film Properties

PVD films are often very thin, smooth, and durable. The process allows for precise control over thickness and structure.

CVD films can be made thicker and can offer unique properties based on the chemical reactions involved. However, they can sometimes be rougher than PVD coatings depending on the specific process parameters.

Understanding the Trade-offs

Neither technology is universally superior. Your decision will hinge on understanding their inherent limitations.

The Temperature Constraint of CVD

The primary drawback of CVD is its high operating temperature. This requirement immediately disqualifies a wide range of substrate materials that would be softened, melted, or otherwise damaged by the heat.

The Line-of-Sight Limitation of PVD

PVD's primary challenge is its line-of-sight nature. Uniformly coating complex shapes, internal bores, or sharp corners requires complex fixturing and rotation, which can increase process time and cost.

Chemical Byproducts and Complexity

CVD processes often produce hazardous chemical byproducts that require careful management and disposal. The chemistry itself can be more complex to control compared to the physical nature of PVD.

How to Apply This to Your Project

Your choice should be guided by the non-negotiable requirements of your project.

- If your primary focus is coating heat-sensitive materials: PVD is the clear choice due to its significantly lower process temperatures.

- If your primary focus is achieving a uniform coating on complex 3D shapes: CVD's excellent conformality makes it the superior option.

- If your primary focus is depositing a very pure, simple metallic layer: PVD is often more straightforward as the source material is the coating material.

- If your primary focus is creating a coating with a specific chemical composition not easily produced as a solid: CVD provides the flexibility to form unique materials through chemical reactions.

Ultimately, understanding that PVD is a physical deposition and CVD is a chemical one is the key to selecting the right tool for your engineering challenge.

Summary Table:

| Feature | PVD (Physical Vapor Deposition) | CVD (Chemical Vapor Deposition) |

|---|---|---|

| Process Type | Physical (vaporization) | Chemical (gas reaction) |

| Operating Temperature | Low (250°C - 450°C) | High (450°C - 1050°C+) |

| Coating Coverage | Line-of-sight | Conformal (covers complex shapes) |

| Best For | Heat-sensitive materials, simple geometries | High-temperature substrates, complex 3D parts |

Still unsure which deposition process is right for your application?

At KINTEK, we specialize in laboratory equipment and consumables for thin-film deposition. Our experts can help you navigate the complexities of PVD vs. CVD to find the optimal solution for your specific materials, part geometry, and performance requirements.

Contact our technical team today to discuss your project and discover how our solutions can enhance your research or production process.

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What is the difference between CVD and PECVD? Choose the Right Thin-Film Deposition Method

- Why is PECVD better than CVD? Achieve Superior Low-Temperature Thin Film Deposition

- What is the difference between thermal CVD and PECVD? Choose the Right Thin-Film Deposition Method

- What is the precursor gas in PECVD? The Key to Low-Temperature Thin Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process