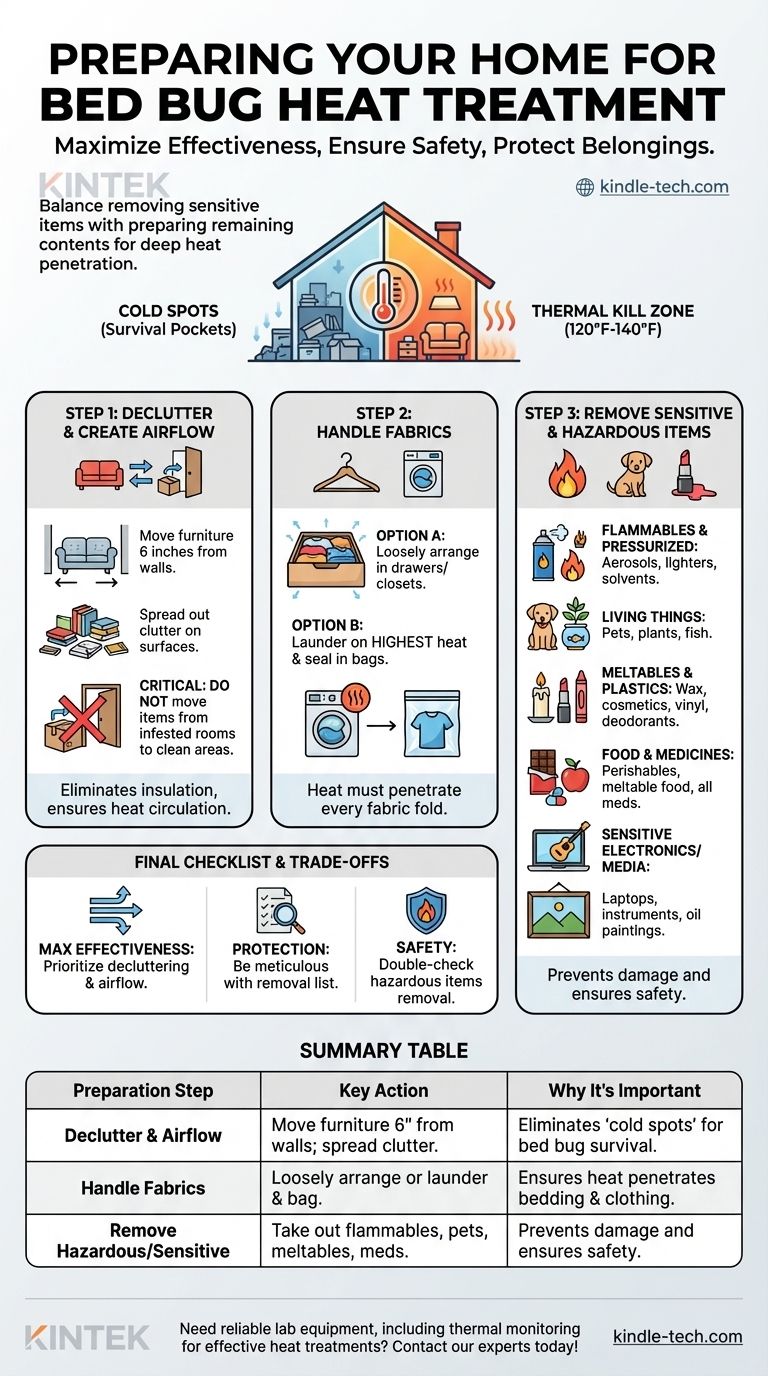

To prepare your house for a bed bug heat treatment, you must remove all heat-sensitive and hazardous items while simultaneously preparing the remaining contents to ensure hot air can penetrate every possible hiding spot. This involves decluttering, providing space for airflow, and loosely arranging fabrics so the lethal temperature can be reached everywhere. The success of the treatment is directly tied to the quality of your preparation.

The core challenge of heat treatment prep is balancing two opposing goals: removing items that could be damaged or create a hazard, while leaving all potentially infested items inside to be treated. Your goal is to create an environment where heat can flow freely and deeply into every object left in your home.

Why Proper Preparation is Non-Negotiable

A professional heat treatment aims to raise the ambient temperature of your home to between 120°F and 140°F (approximately 50°C to 60°C). This thermal "kill zone" must be maintained for several hours to penetrate furniture, walls, and deep clutter.

The Problem of "Cold Spots"

Any area that doesn't reach the target temperature becomes a "cold spot." These areas act as survival pockets for bed bugs, allowing them to emerge after the treatment and re-infest your home.

Proper preparation is your primary tool for eliminating these potential cold spots and ensuring the treatment is successful on the first attempt.

Step 1: Declutter and Create Airflow

Clutter is the primary enemy of effective heat treatment. Piles of items create dense insulation that hot air cannot easily penetrate.

Do Not Remove Infested Items

It is critical that you do not move items from an infested room to a non-infested room or take them out of the home (unless specified below). Moving boxes or bags of personal belongings is the most common way to spread bed bugs to a new area.

Prepare Furniture for Treatment

Move furniture at least 6 inches away from the walls. This allows hot air to circulate around and behind every piece, ensuring heat penetrates thoroughly.

Address Clutter Directly

Go through piles of clutter on floors or surfaces. Spread these items out loosely on the floor to maximize their exposure to the hot air.

Step 2: Handle Clothing, Linens, and Fabrics

Bed bugs frequently hide in bedding, clothes, and other textiles. How you prepare them is crucial.

Option 1: Treat Fabrics in Place

Leave clothing in dresser drawers, but do not pack them tightly. Remove a few items from each drawer to create air gaps. You can also hang clothes in closets, ensuring there is space between each item.

Option 2: Launder and Remove

Alternatively, you can wash and dry all clothing, linens, and curtains on the highest possible heat setting. Immediately place the clean, dry items into sealed plastic bags and store them outside the treatment area until the process is complete.

Step 3: Remove Heat-Sensitive and Hazardous Items

This is the most important step for preventing damage and ensuring safety. The following items must be removed from your home before the heat treatment begins.

Flammables and Pressurized Items

This is a critical safety step. Remove all aerosol cans (like hairspray or cleaners), lighters, firearms, ammunition, fire extinguishers, and any flammable liquids like solvents or lamp oil.

Living Things

All pets (including fish in aquariums) and houseplants must be removed. The high temperatures are lethal to them.

Wax, Plastics, and Cosmetics

Heat will melt these items, creating a mess and potentially ruining them. This includes candles, lipstick, crayons, deodorants, and other cosmetics. It's also wise to remove vinyl records and vinyl blinds.

Food, Beverages, and Medicines

Remove all food that can melt (like chocolate), fresh produce, and alcoholic beverages like wine, which can spoil. All prescription and over-the-counter medicines must also be removed, as heat can alter their chemical composition and effectiveness.

Sensitive Electronics and Media

While many electronics can withstand the heat, it is often best to err on the side of caution. Consult with your treatment provider, but consider removing sensitive items like laptops, musical instruments, oil paintings, CDs, and DVDs.

Understanding the Trade-offs

Proper preparation involves making informed decisions to avoid common pitfalls.

The Risk of Spreading the Infestation

The biggest mistake is moving an infested item out of the treatment area. If you must remove a delicate object that cannot be heated (like a valuable painting), inspect it meticulously or have it treated separately by a professional.

The Risk of Incomplete Treatment

Failing to declutter or provide airflow directly increases the chance of treatment failure. A cluttered room full of tightly packed drawers is almost guaranteed to have cold spots where bed bugs will survive.

The Potential for Minor Damage

Be aware that extremely high heat can sometimes affect sensitive items. It may cause glued joints in older furniture to loosen or warp very delicate wood items. This risk is minimal but real.

Final Checklist Before the Professionals Arrive

Use this as a final guide to ensure your home is ready for a successful treatment.

- If your primary focus is maximum effectiveness: Prioritize decluttering above all else. Spread items out and move all furniture away from the walls to guarantee airflow.

- If your primary focus is protecting your belongings: Be meticulous in identifying and removing every item on the heat-sensitive list, from candles to medications.

- If your primary focus is safety: Double-check that all living things, pressurized cans, and flammable materials have been completely removed from the property.

By taking these steps, you are doing everything in your power to ensure the heat treatment is successful, safe, and final.

Summary Table:

| Preparation Step | Key Action | Why It's Important |

|---|---|---|

| Declutter & Create Airflow | Move furniture 6 inches from walls; spread out clutter. | Eliminates 'cold spots' where bed bugs can survive. |

| Handle Fabrics | Loosely arrange clothes in drawers or launder and bag them. | Ensures heat penetrates common hiding spots like bedding and clothing. |

| Remove Hazardous/Sensitive Items | Take out flammables, pets, plants, medicines, and heat-sensitive objects. | Prevents damage and ensures safety during high-temperature treatment. |

Need reliable equipment for pest control or laboratory analysis? KINTEK specializes in lab equipment and consumables, serving laboratories with precision tools for environmental testing, including thermal monitoring devices to ensure effective heat treatments. Let us support your success—contact our experts today to find the right solutions for your needs!

Visual Guide

Related Products

- High Temperature Constant Temperature Heating Circulator Water Bath Chiller Circulator for Reaction Bath

- Desktop Fast Laboratory Autoclave Sterilizer 35L 50L 90L for Lab Use

- Vacuum Cold Trap Direct Cold Trap Chiller

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Wall Mounted Water Distillation Unit

People Also Ask

- What is the primary function of a laboratory drying oven? Ensure Purity in Ni-Al2O3-TiO2 Composite Pretreatment

- Which is the most applied area for additive manufacturing? From Prototyping to High-Value Production

- What is the speed of Rotavap? Optimize Evaporation with the Right RPM for Your Solvent

- What are the advantages of physical vapour deposition method? Achieve Superior, Durable Surface Coatings

- Does THC evaporate over time? The Truth About Potency Loss and Preservation

- Why is DC sputtering used for metals? Unlock Faster, More Cost-Effective Metal Deposition

- What data can be obtained from laboratory high-temperature thermal simulation equipment? Master SA508 Alloy Performance

- What are the defects in the heat treatment process? Prevent Cracking, Warping, and Soft Spots