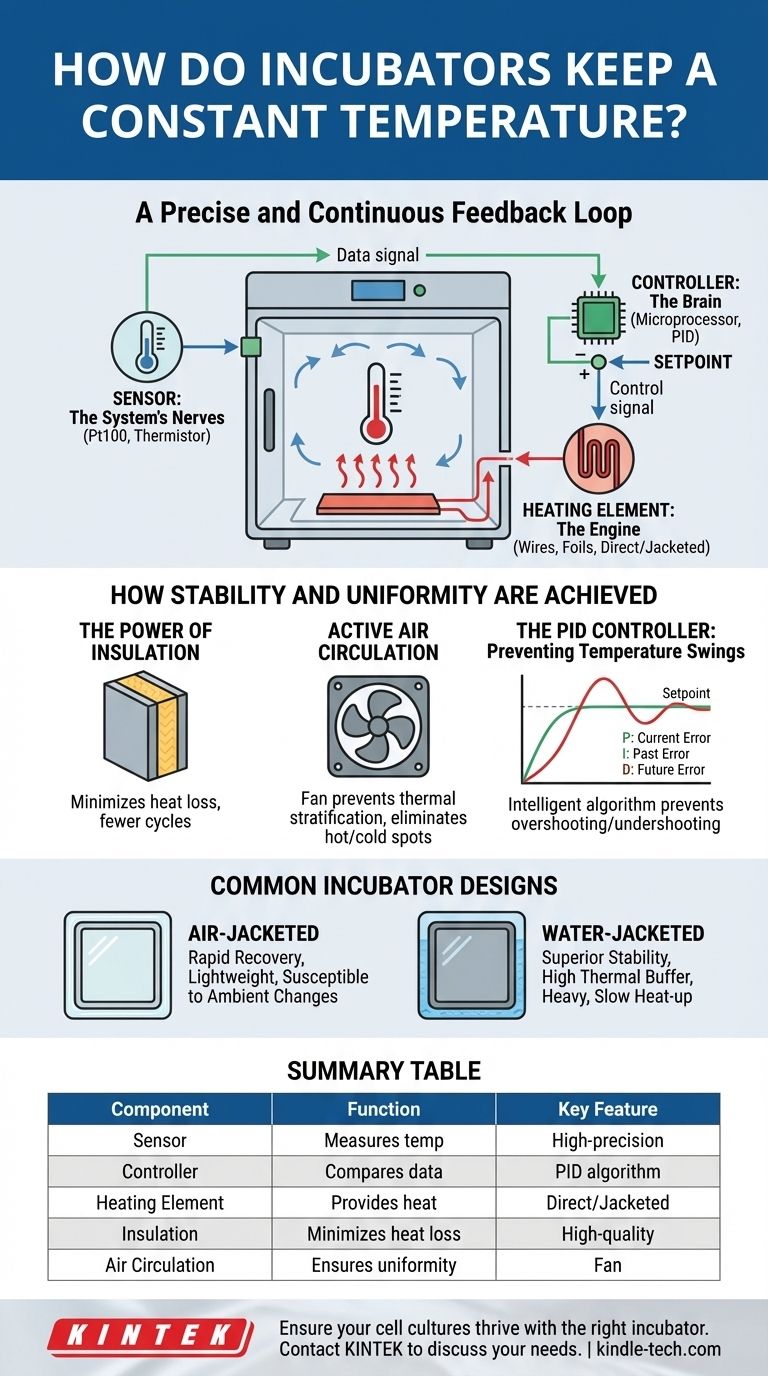

At their core, incubators maintain a constant temperature through a precise and continuous feedback loop. A highly sensitive temperature sensor constantly measures the internal environment. This reading is fed to a microprocessor controller, which compares it to the desired temperature (the "setpoint") and instantly activates or deactivates a heating system to correct any deviation, no matter how small.

The challenge of maintaining a "constant" temperature is not a static state but a dynamic balancing act. True stability is achieved through a combination of rapid sensing, intelligent control algorithms, and physical design elements like insulation and air circulation that work together to resist external changes and ensure internal uniformity.

The Anatomy of Temperature Control

To understand how an incubator works, you must first understand its three critical components: the sensor, the controller, and the heating element. These parts form a classic control system loop.

The Sensor: The System's Nerves

The entire system's accuracy begins with the sensor. It must detect minuscule temperature fluctuations reliably.

Most modern incubators use high-precision sensors like platinum resistance thermometers (PRT or Pt100) or thermistors. These devices change their electrical resistance in a very predictable way as temperature changes, allowing the controller to get an exact reading.

The Controller: The Brain of the Operation

The controller is the microprocessor that makes decisions. It continuously compares the real-time data from the sensor to the user-defined setpoint.

When the sensor reports a temperature below the setpoint, the controller sends a signal to activate the heating element. When the temperature reaches or exceeds the setpoint, it cuts the power. This simple "on/off" cycle is the most basic form of control.

The Heating Element: The Engine

The heating element is typically a system of wires or foils that heat up when electricity passes through them. These elements are strategically placed to distribute heat.

In direct-heat incubators, these elements are inside the chamber walls. In jacketed incubators, they heat a surrounding buffer of air or water, which then radiates heat evenly into the main chamber.

How Stability and Uniformity Are Achieved

Simply turning a heater on and off is not enough to guarantee the constant, uniform temperature required for sensitive biological applications. Sophisticated incubators employ additional engineering to achieve true stability.

The Power of Insulation

High-quality insulation is the first line of defense against ambient temperature fluctuations. By minimizing heat loss to the surrounding room, the incubator reduces the amount of work the heating system has to do, leading to fewer and smaller heating cycles and greater stability.

Active Air Circulation

Temperature uniformity (ensuring the top of the chamber is the same temperature as the bottom) is just as important as stability.

Most incubators use a small, gentle fan to circulate the air. This forced convection prevents thermal stratification, eliminating hot and cold spots and ensuring every sample experiences the exact same temperature.

The PID Controller: Preventing Temperature Swings

Advanced incubators use a PID (Proportional-Integral-Derivative) controller. This is an intelligent algorithm that goes far beyond simple on/off control to prevent overshooting and undershooting the setpoint.

- Proportional (P): Reacts to the current error. The further the temperature is from the setpoint, the more power it applies.

- Integral (I): Corrects for past error. It adjusts for small, steady-state errors that the proportional term might miss, "learning" to hold the temperature more precisely over time.

- Derivative (D): Predicts future error. It dampens the heating response as the temperature approaches the setpoint, preventing it from overshooting the target.

Together, these three terms allow the incubator to raise the temperature quickly and then "soften the landing" to lock onto the setpoint with extreme precision.

Understanding the Trade-offs: Common Incubator Designs

The physical design of an incubator has a major impact on its performance. The two most common designs are air-jacketed and water-jacketed.

Air-Jacketed Incubators

These incubators are surrounded by a layer of air that is heated and serves as an insulator.

They heat up and recover temperature quickly after a door opening because air has a low thermal mass. This makes them lighter and easier to set up, but also more susceptible to fluctuations in room temperature.

Water-Jacketed Incubators

These models are surrounded by a large reservoir of heated water. Water's high thermal capacity makes it an exceptional thermal buffer.

This design provides superior thermal stability and is highly resistant to ambient temperature changes or power outages. However, these incubators are very heavy, take a long time to heat up initially, and require more maintenance to prevent water contamination.

Making the Right Choice for Your Application

Selecting the correct incubator design is critical for experimental success. Your choice depends on the specific demands of your work.

- If your primary focus is maximum thermal stability for sensitive, long-term cultures: A water-jacketed incubator's ability to buffer against external changes is often the superior choice.

- If your primary focus is rapid temperature recovery in a busy lab with frequent door openings: An air-jacketed or direct-heat model with forced air circulation will serve you better.

- If your primary focus is budget and simple setup for general-purpose applications: A modern direct-heat incubator with a quality PID controller offers a reliable and cost-effective solution.

Understanding these engineering principles empowers you to look beyond the setpoint on the screen and choose the instrument that truly protects your work.

Summary Table:

| Component | Function | Key Feature |

|---|---|---|

| Sensor | Measures internal temperature | High-precision (e.g., Pt100, thermistor) |

| Controller | Compares sensor data to setpoint | PID algorithm for precision |

| Heating Element | Provides heat to the chamber | Direct-heat or jacketed design |

| Insulation | Minimizes heat loss | High-quality materials for stability |

| Air Circulation | Ensures uniform temperature | Fan for forced convection |

Ensure your cell cultures thrive with the right incubator.

Choosing the correct incubator is critical for the success of your sensitive biological work. The precise temperature control, stability, and uniformity provided by a high-quality incubator are non-negotiable for reproducible results.

At KINTEK, we specialize in laboratory equipment, including a range of incubators designed to meet the rigorous demands of modern research. Whether you need the rapid recovery of an air-jacketed model or the superior stability of a water-jacketed incubator, we have the expertise to help you select the perfect instrument for your application.

Let our specialists guide you to the ideal solution for your lab. Contact KINTEK today to discuss your incubator needs and ensure your experiments are built on a foundation of reliable temperature control.

Visual Guide

Related Products

- Shaking Incubators for Diverse Laboratory Applications

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Infrared Heating Quantitative Flat Plate Press Mold

- Double Plate Heating Press Mold for Lab

- Laboratory High Pressure Vacuum Tube Furnace

People Also Ask

- Why is a constant temperature shaking incubator necessary for antibacterial experiments? Ensure Valid Results

- What role does a constant temperature orbital shaker play in biomass processing? Maximize Your Fermentation Yields

- Why is a constant temperature shaker required during the impregnation of manganese salts onto activated carbon?

- What is the importance of a constant temperature shaking incubator? Ensure Precise Bacterial Growth and Membrane Tests

- What is the purpose of a constant temperature incubator shaker? Master Quercetin Adsorption on Nanocomposites