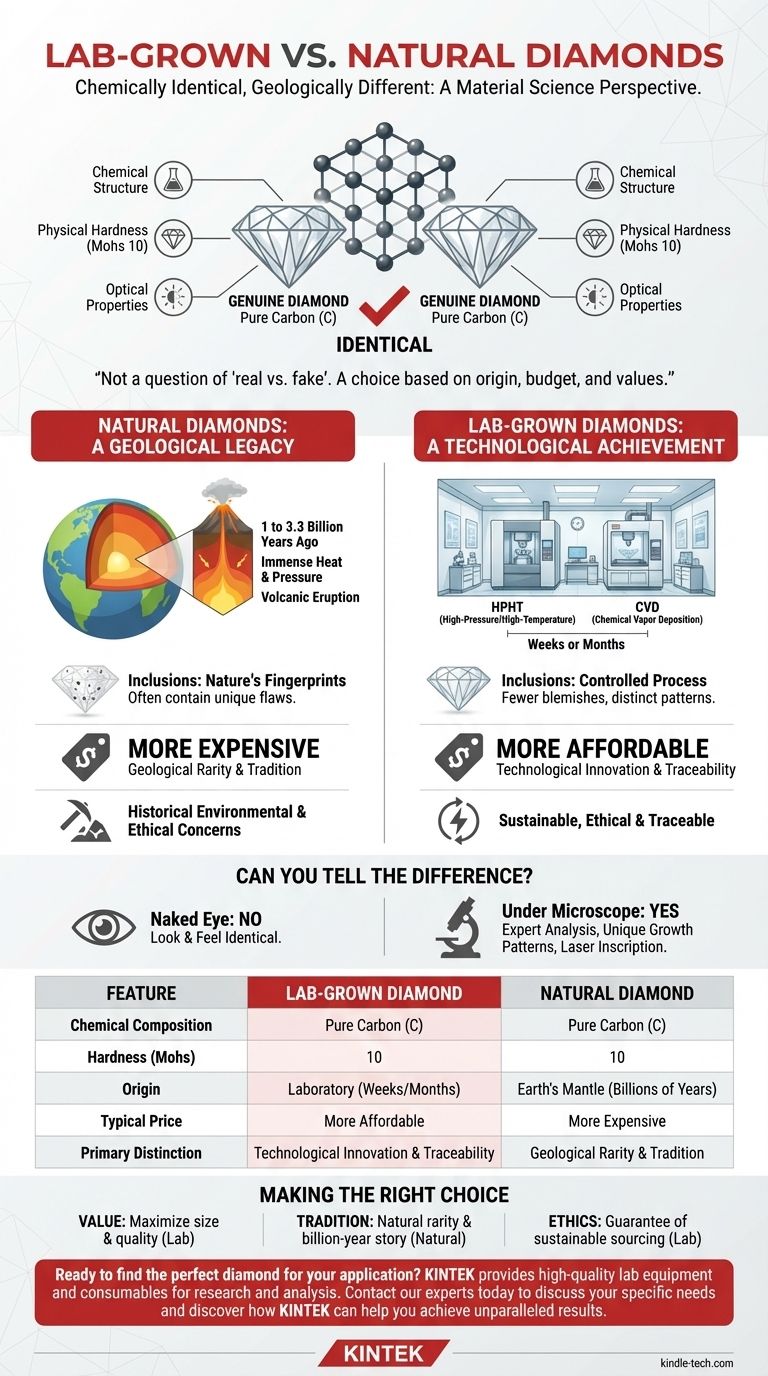

From a material science perspective, lab-grown and natural diamonds are identical. They share the exact same chemical structure, physical hardness, and optical properties, making them both genuine diamonds. The only fundamental difference between them is their origin: one is created by technology in a controlled environment, while the other is formed by nature over billions of years.

The choice between a lab-grown and a natural diamond is not a question of "real vs. fake." It is a decision based on origin, budget, and the value you place on technological innovation versus geological rarity.

What Makes a Diamond a Diamond?

To compare the two, we must first establish the baseline. A diamond, by definition, is a specific material with distinct properties, regardless of its source.

The Unchanging Chemical Blueprint

Both lab-grown and natural diamonds are composed of pure carbon atoms arranged in a crystal lattice structure. This specific arrangement is what gives a diamond its renowned strength and brilliance.

Identical Physical and Optical Properties

Because their atomic structure is the same, both types exhibit identical physical characteristics. They register a 10 on the Mohs hardness scale and disperse light in the same way, creating the sparkle and fire that diamonds are known for.

The Core Difference: Origin and Formation

The entire distinction between these two categories of diamond stems from their creation story. One is a product of immense geological time, while the other is a product of human ingenuity.

Natural Diamonds: A Geological Legacy

Natural diamonds formed deep within the Earth's mantle between 1 and 3.3 billion years ago. They were subjected to immense heat and pressure before being brought to the surface through ancient volcanic eruptions. Their creation was a chaotic, uncontrolled natural process.

Lab-Grown Diamonds: A Technological Achievement

Lab-grown diamonds are created in highly controlled laboratory settings using advanced technology. Methods like High-Pressure/High-Temperature (HPHT) or Chemical Vapor Deposition (CVD) replicate the conditions of the Earth's mantle, allowing a diamond crystal to grow in a matter of weeks or months.

Understanding the Practical Trade-offs

While chemically identical, the different origins create practical distinctions that are critical for any potential buyer to understand.

The Impact on Clarity and Inclusions

Natural diamonds often contain tiny imperfections, called inclusions, which are other minerals or structural flaws trapped during their violent formation. These are considered nature's "fingerprints."

Lab-grown diamonds can also have inclusions, but they are typically of a different nature. For example, some HPHT diamonds may have tiny metallic inclusions from the growth process. Because the environment is controlled, lab diamonds often have fewer and less significant blemishes.

The Decisive Factor of Price

This is the most significant market differentiator. Due to a much shorter and more efficient supply chain, lab-grown diamonds are considerably more affordable than natural diamonds of comparable size and quality. A buyer's budget can often secure a much larger or higher-grade lab-grown stone.

The Ethical and Environmental Considerations

The lab-grown diamond industry positions its products as a more sustainable and ethical choice. This avoids the environmental impact and potential for human rights issues ("conflict diamonds") historically associated with some mining operations.

Can You Tell the Difference?

This is a common and important question. The answer depends entirely on who is looking and what tools they are using.

To the Naked Eye: No

Without specialized equipment, even a trained gemologist cannot distinguish between a lab-grown and a natural diamond. They look and feel identical.

Under the Microscope: Yes

Expert gemologists can identify the origin using powerful magnification. They look for the unique growth patterns and types of inclusions characteristic of either a natural or a lab-created process. Furthermore, many lab-grown diamonds are laser-inscribed on the girdle with a serial number and a declaration of their origin.

Making the Right Choice for Your Goal

The "better" diamond is entirely subjective and depends on your priorities.

- If your primary focus is maximizing size and quality for your budget: A lab-grown diamond offers superior value, allowing you to purchase a larger and clearer stone for the same price.

- If your primary focus is the tradition and romance of natural rarity: A natural diamond, with its billion-year-old story and origin deep within the Earth, holds a unique symbolic value.

- If your primary focus is a guarantee of ethical and environmental sourcing: A lab-grown diamond provides complete traceability and avoids the complexities associated with natural diamond mining.

Ultimately, both are valid choices, and the best diamond is the one that aligns with your personal values and purpose.

Summary Table:

| Feature | Lab-Grown Diamond | Natural Diamond |

|---|---|---|

| Chemical Composition | Pure Carbon (C) | Pure Carbon (C) |

| Hardness (Mohs Scale) | 10 | 10 |

| Origin | Laboratory (Weeks/Months) | Earth's Mantle (Billions of Years) |

| Typical Price | More Affordable | More Expensive |

| Primary Distinction | Technological Innovation & Traceability | Geological Rarity & Tradition |

Ready to find the perfect diamond for your application? Whether you're a researcher needing precise materials or a jeweler sourcing gems, the right equipment is key to your success. KINTEK specializes in providing high-quality lab equipment and consumables to support your work. Contact our experts today to discuss your specific needs and discover how KINTEK can help you achieve unparalleled results with the right tools for analysis and creation.

Visual Guide

Related Products

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What is a microwave plasma source? A Key Tool for Advanced Materials and Manufacturing

- What is MPCVD? Unlock Atom-by-Atom Precision for High-Purity Materials

- What is deposition of diamond films? Grow High-Performance Diamond Coatings with CVD

- What is the difference between MPCVD and HFCVD? Choose the Right CVD Method for Your Application

- Does the chemical vapor deposition be used for diamonds? Yes, for Growing High-Purity Lab Diamonds

- How do you make a lab diamond? Discover the HPHT and CVD Methods Explained

- What advantages does a Multimode Cavity (MCC) reactor offer for large-area diamond films? Scale Beyond 4-Inch Wafers

- What are the advantages of diamond cutting tool material? Achieve Superior Precision and Productivity