Bending a quartz tube is a specialized process that requires heating it to its softening point using high-temperature equipment. Unlike common glass, quartz (fused silica) has an extremely high working temperature, around 1600°C (2912°F), which is far beyond the reach of standard propane or MAPP gas torches. The procedure demands precise temperature control, even rotation, and a slow cooling process to prevent stress fractures.

The core challenge of bending quartz is not the action of bending itself, but the extreme difficulty of achieving and managing the necessary temperatures safely. For any application requiring precision or reliability, this work is best outsourced to a professional scientific glassblower.

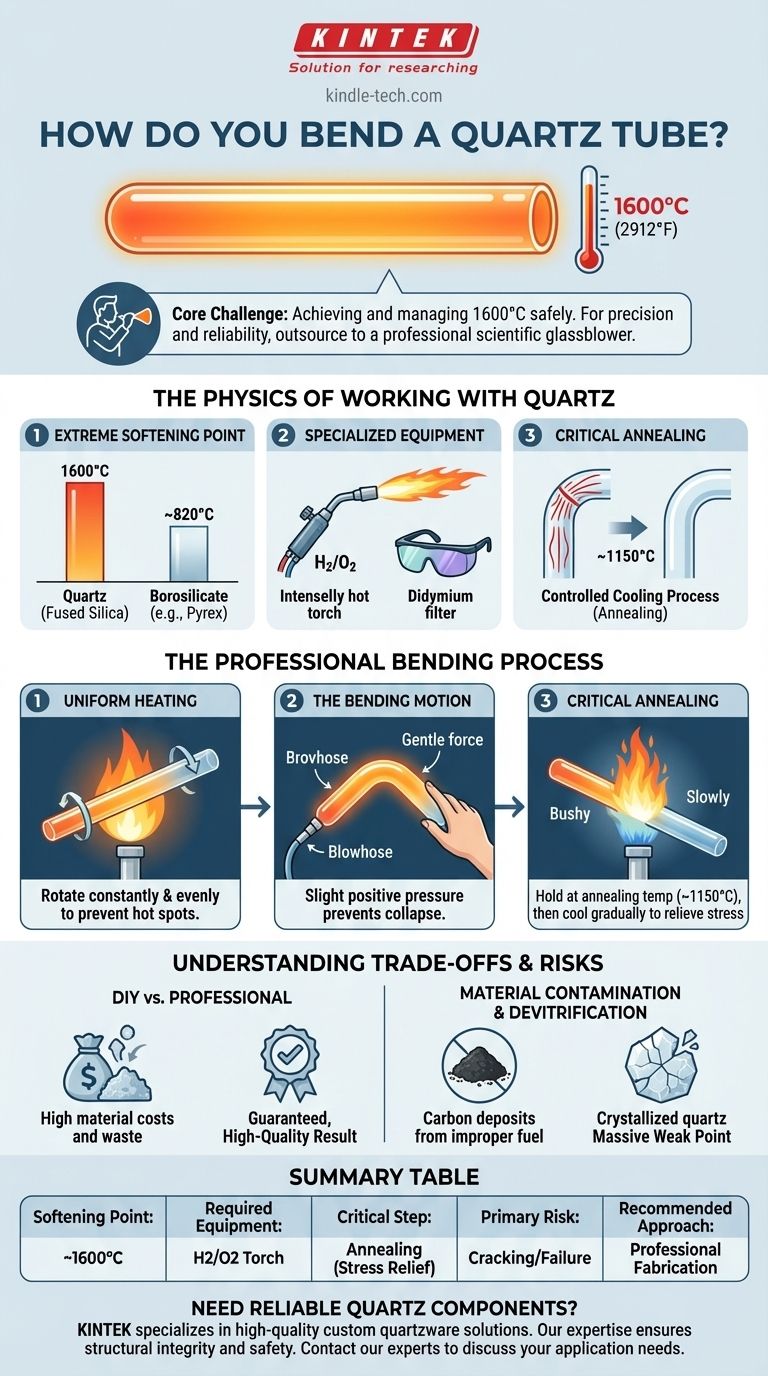

The Physics of Working with Quartz

To understand why bending quartz is so difficult, you must first understand its unique material properties, which differ significantly from common borosilicate glass (like Pyrex).

The Extreme Softening Point

Quartz is not technically a "glass" but a high-purity amorphous silica. Its softening point—the temperature at which it becomes malleable—is approximately 1600°C.

This is nearly double the softening point of borosilicate glass (~820°C). The 1100°C-1200°C range mentioned for furnace use is its maximum service temperature, where it remains rigid. Deformation at 1200°C is a sign of structural failure, not a workable state.

The Need for Specialized Equipment

Reaching and sustaining 1600°C requires a specialized torch. The industry standard is a hydrogen-oxygen (H2/O2) torch, also known as a hydro-oxy torch.

These torches produce a clean, intensely hot flame necessary to work the quartz. You will also need specialized safety glasses with a didymium filter (often Shade 5 or higher) to protect your eyes from the intense sodium flare and infrared radiation.

The Importance of Annealing

While quartz has excellent thermal shock resistance, any localized heating and bending introduces significant internal stress into the material's structure.

If this stress is not relieved, the tube will be extremely fragile and likely crack later, either spontaneously or during temperature changes. This stress relief is achieved through a controlled cooling process called annealing.

The Professional Bending Process

A scientific glassblower follows a precise workflow to ensure a strong, dimensionally stable bend.

Step 1: Uniform Heating

The glassblower uses the torch to heat a wide, even band around the area to be bent. The tube must be rotated constantly and evenly to prevent hot spots.

Uneven heating is the most common cause of failure, as one side will become soft while the other remains rigid, causing the tube to collapse or bubble.

Step 2: The Bending Motion

Once the heated section glows a bright orange-white and begins to yield under its own weight, a gentle and steady force is applied to create the bend.

The tube is kept under slight positive pressure by blowing through a swivel at one end. This prevents the softened tube walls from collapsing inward during the bend.

Step 3: Critical Annealing

Immediately after the bend is formed, the glassblower reduces the flame and "bathes" the entire bent area in a large, bushy flame.

This holds the piece at its annealing temperature (around 1150°C) to allow the internal stresses to relax. The flame is then slowly withdrawn, allowing the area to cool gradually and evenly. Skipping this step guarantees future failure.

Understanding the Trade-offs and Risks

Attempting to bend quartz without the proper training and equipment is fraught with challenges.

DIY vs. Professional Fabrication

The primary trade-off is cost versus reliability. While attempting it yourself may seem cheaper, the high cost of quartz tubing, specialized torches, and safety equipment adds up.

Factoring in the high likelihood of failed attempts and material waste, outsourcing to a professional glassblower is often more cost-effective for a guaranteed, high-quality result.

Material Contamination and Devitrification

Using an improper fuel, like propane, can deposit carbon into the quartz, weakening it. Furthermore, holding quartz at high temperatures for too long can cause it to devitrify, or crystallize.

This crystallized area (cristobalite) has a different coefficient of thermal expansion and will create a massive weak point that will crack upon cooling.

The High Cost of Failure

A poorly executed bend is more than just a cosmetic flaw; it is a structural defect. For any scientific or industrial process, especially those involving vacuum or pressure, using a compromised quartz component is a significant safety risk.

Making the Right Choice for Your Goal

Your approach should be dictated entirely by the final application of the component.

- If your primary focus is a non-critical prototype or learning the skill: You can attempt this with the correct hydrogen torch and safety gear, but you must plan for a steep learning curve and significant material waste.

- If your primary focus is a reliable, dimensionally accurate part for research or production: Outsource the work to a professional scientific glassblower. This is the only way to guarantee a safe, stress-free, and functional component.

- If your primary focus is simply routing a high-temperature process: Evaluate if a stock, pre-fabricated bent quartz tube or a custom assembly using straight tubes and connectors can meet your needs without requiring custom bending.

Ultimately, understanding the extreme demands of working with quartz is the first step toward achieving a successful and safe outcome.

Summary Table:

| Key Consideration | Detail |

|---|---|

| Softening Point | ~1600°C (2912°F) |

| Required Equipment | Hydrogen-Oxygen (H2/O2) Torch |

| Critical Step | Annealing to relieve internal stress |

| Primary Risk | Cracking from stress or improper cooling |

| Recommended Approach | Professional fabrication for reliable results |

Need a reliable, professionally fabricated quartz component for your laboratory? Bending quartz requires extreme precision and specialized equipment to ensure structural integrity and safety. KINTEK specializes in high-quality lab equipment and consumables, including custom quartzware solutions. Our expertise ensures your components are fabricated correctly, saving you time, cost, and the risk of material failure. Contact our experts today to discuss your specific application needs and get a durable, stress-free solution tailored for your research or production.

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory High Pressure Vacuum Tube Furnace

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is the function of a tube furnace? Achieve Precise High-Temperature Processing in a Controlled Atmosphere

- How do you clean a tube furnace tube? A Step-by-Step Guide to Safe and Effective Cleaning

- Why is an Alumina Ceramic Tube Support Necessary for 1100°C Experiments? Ensure Data Accuracy and Chemical Inertness

- What are the applications of tube furnace? Unlock Precise High-Temperature Processing

- What is the ceramic tube high temperature? From 1100°C to 1800°C, Choose the Right Material