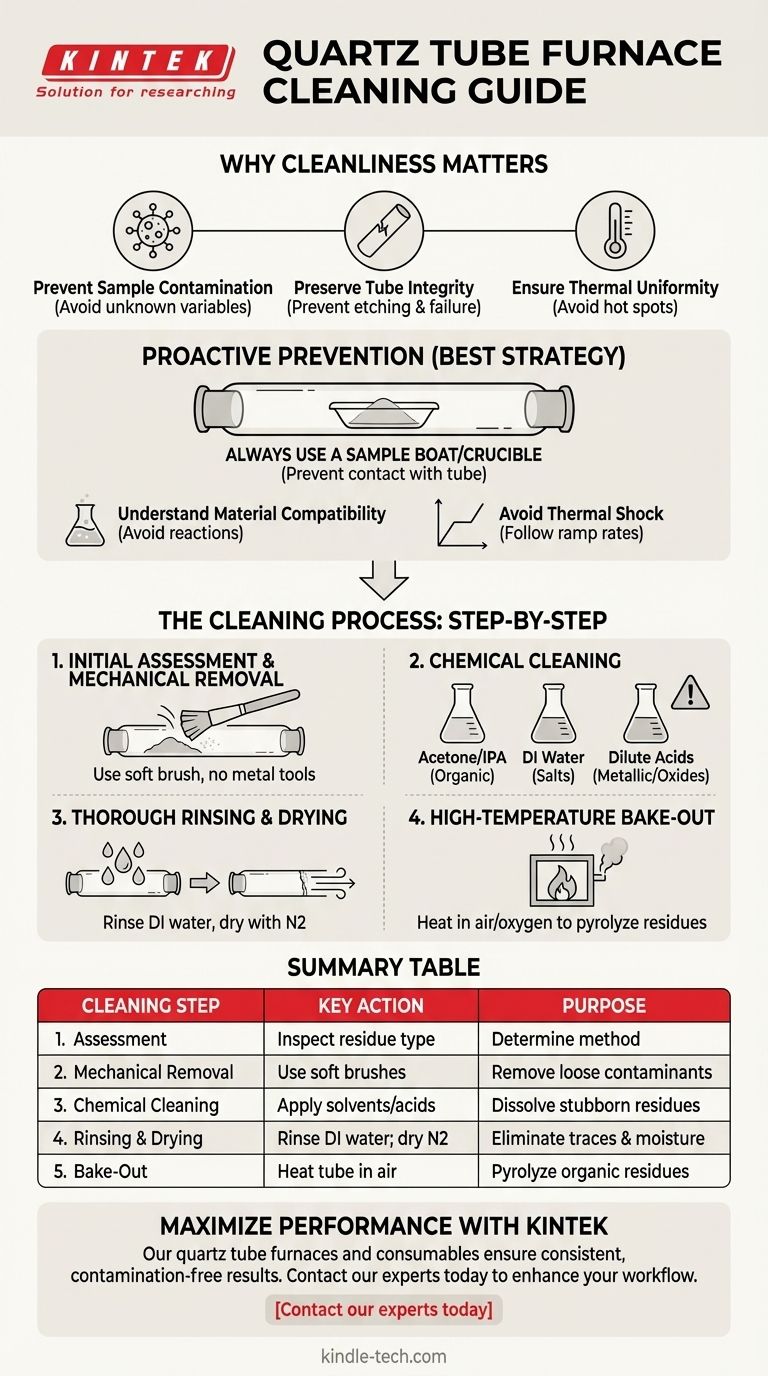

To properly clean a quartz tube furnace, you must first identify the type of residue you are dealing with. The process generally involves a combination of careful mechanical removal of loose material, chemical cleaning with appropriate solvents or mild acids, thorough rinsing with deionized water, and a final high-temperature bake-out to ensure all contaminants are gone.

The most effective strategy for maintaining a quartz tube is not reactive cleaning but proactive prevention. Using sample crucibles and understanding material compatibility minimizes the need for aggressive cleaning procedures that can damage the tube, shorten its lifespan, and compromise experimental results.

Why Cleanliness is the Foundation of Good Results

The quartz tube is the heart of your furnace—it's the reaction chamber where your work takes place. Its condition directly impacts the quality and reliability of your outcomes.

Preventing Sample Contamination

Any residue left from a previous run can vaporize or react during your next experiment. This introduces unknown variables, contaminates your sample, and invalidates your results.

Preserving Tube Integrity

Certain materials, especially at high temperatures, can react with and etch the silicon dioxide (SiO₂) of the quartz. This creates microscopic weak points that can lead to cracks and catastrophic failure under thermal stress or pressure changes.

Ensuring Thermal Uniformity

A layer of residue can act as an insulator or create hot spots, disrupting the uniform temperature profile within the tube. This leads to inconsistent heating of your sample and unreliable thermal processes.

A Proactive Approach: Preventing Contamination

The best cleaning method is to avoid the need for it. Integrating these practices into your workflow will dramatically extend the life of your quartz tubes.

Always Use a Sample Boat or Crucible

This is the single most important rule. As noted in furnace documentation, materials should never be placed directly on the furnace tube. Using a ceramic (like alumina) or quartz boat contains the sample and prevents it from ever touching the tube wall.

Understand Material Compatibility

Before heating any substance, confirm that it will not react with SiO₂ at your target temperature. Some metals and alkali compounds are particularly aggressive and can permanently damage the quartz.

Avoid Thermal Shock

Rapid heating or cooling creates immense stress in the quartz, making it more susceptible to cracking. Always follow the manufacturer's recommended ramp rates, especially when the tube is new or has been recently cleaned.

The Cleaning Process: A Step-by-Step Guide

When cleaning is unavoidable, follow a systematic and gentle approach.

Step 1: Initial Assessment and Mechanical Removal

Once the tube is cool and safely removed, inspect the residue. If the material is loose (like soot or powder), you can often remove it by tilting the tube or using a long, soft-bristled brush. Never use metal tools that could scratch the interior.

Step 2: Chemical Cleaning

The choice of chemical depends on the contaminant. Start with the mildest solvent possible.

- For organic residues: Use solvents like acetone or isopropyl alcohol (IPA).

- For water-soluble salts: Use high-purity deionized (DI) water.

- For metallic films or oxides: This is more complex and may require dilute acids. Always perform this with extreme caution and proper personal protective equipment (PPE).

Step 3: Thorough Rinsing and Drying

After any chemical wash, rinse the tube multiple times with deionized water to remove all traces of the cleaning agent. Afterward, dry the tube completely, either by air drying or using a gentle stream of clean nitrogen gas.

Step 4: High-Temperature Bake-Out (Pyrolysis)

For stubborn carbon-based residues, a final cleaning step can be a bake-out. Place the empty, dry tube back in the furnace and heat it in the presence of air or oxygen to burn off any remaining organic traces.

Understanding the Risks and Trade-offs

Aggressive cleaning can cause more harm than good. Understanding the limitations is key to making the right decision.

The Danger of Aggressive Chemicals

Strong acids or bases (like aqua regia or piranha solution) can be effective, but they are extremely hazardous and can etch the quartz surface. This microscopic damage accelerates future contamination and creates failure points. This should be an absolute last resort.

The Risk of Mechanical Scratching

A scratch is a stress concentration point. When the tube is heated, this tiny flaw can easily propagate into a full crack, ruining the tube. Always use soft tools or avoid mechanical contact altogether.

The Limitations of Thermal Cleaning

A bake-out is only effective for materials that will pyrolyze or oxidize cleanly. Some materials may melt and alloy with the quartz, causing irreversible damage. Always know what you are trying to burn off.

Making the Right Choice for Your Goal

Your cleaning and maintenance strategy should be tailored to your specific application and priorities.

- If your primary focus is routine use with organic materials: Prioritize using a sample boat and perform periodic cleaning with solvents like acetone, followed by a DI water rinse and bake-out.

- If your primary focus is processing diverse inorganic compounds: Your top priority is researching material compatibility with quartz before the experiment and always using a crucible.

- If your primary focus is maximum tube lifetime and budget control: Be relentless about preventative measures. A new sample boat is far cheaper than a new quartz tube.

Ultimately, treating your quartz tube with meticulous care is the foundation of reliable and repeatable results in your work.

Summary Table:

| Cleaning Step | Key Action | Purpose |

|---|---|---|

| 1. Assessment | Inspect residue type (organic, metallic, etc.) | Determine the appropriate cleaning method |

| 2. Mechanical Removal | Use soft brushes; avoid metal tools | Safely remove loose contaminants without scratching |

| 3. Chemical Cleaning | Apply mild solvents (e.g., acetone) or dilute acids | Dissolve stubborn residues based on material type |

| 4. Rinsing & Drying | Rinse with deionized water; dry with nitrogen | Eliminate chemical traces and moisture |

| 5. Bake-Out | Heat tube in air to pyrolyze organic residues | Ensure complete removal of carbon-based contaminants |

Maximize the performance and longevity of your lab equipment with KINTEK's expertise.

Our quartz tube furnaces and consumables are designed for precision and durability, ensuring your experiments yield consistent, contamination-free results. Whether you need replacement tubes, sample boats, or technical support on maintenance best practices, KINTEK is here to help.

Contact our experts today to discuss your specific laboratory needs and discover how our solutions can enhance your workflow.

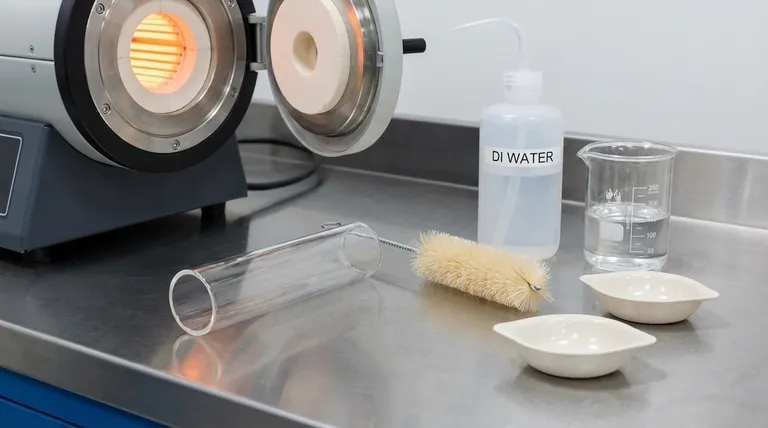

Visual Guide

Related Products

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Vertical Laboratory Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What is the technical value of using a quartz tube reaction chamber for static corrosion testing? Achieve Precision.

- How does an industrial tube furnace ensure the required process conditions for supercritical fluid experimental devices?

- What role does a quartz tube furnace play in hBN synthesis? Optimize Your Chemical Vapor Deposition Results

- Why are quartz tubes preferred for chromium powder combustion? Superior Heat Resistance & Optical Clarity

- What is the primary function of quartz tubes in halide electrolyte synthesis? Ensure Purity & Precise Stoichiometry