To clean PVD-coated stainless steel, use the simplest method available: a soft microfiber cloth, warm water, and a small amount of mild dish soap. The Physical Vapor Deposition (PVD) coating is highly durable and bonded to the steel, but its thinness means the primary goal is to avoid scratching or chemically altering the surface. Aggressive scrubbing or harsh chemicals are unnecessary and will cause damage.

The key to maintaining a PVD finish is understanding that while it is exceptionally hard, it is not invincible. The best cleaning strategy focuses on gently lifting contaminants from the surface without using abrasive force or corrosive chemicals that could harm the thin coating.

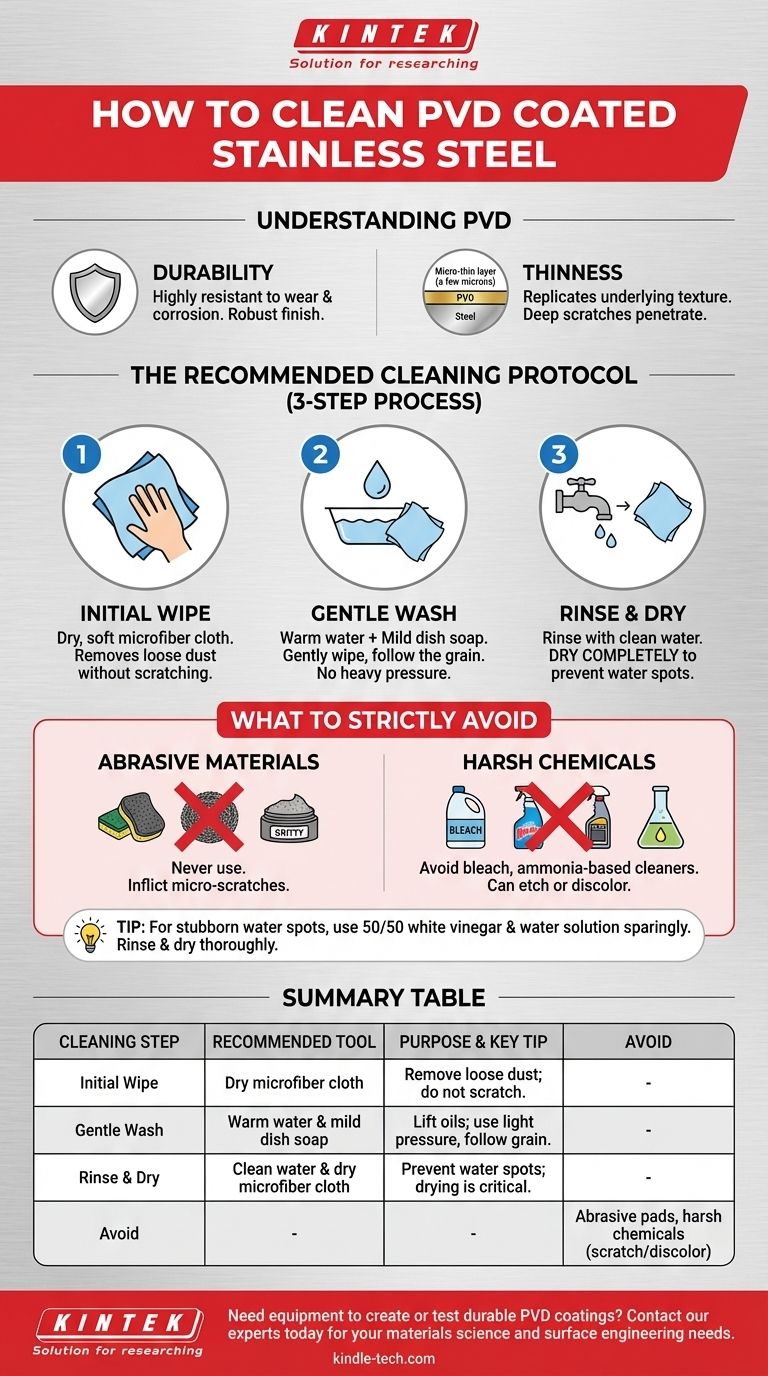

Understanding the PVD Surface

To clean a PVD-coated item correctly, you must first understand the nature of the coating itself. It is not paint; it's a micro-thin layer of material bonded to the stainless steel at a molecular level.

The Durability of PVD

PVD coatings are prized for their hardness and resistance to wear and corrosion. This process provides excellent adhesion, creating a finish that is far more robust than traditional plating or powder coating.

This durability means the surface can easily withstand daily use and regular, gentle cleaning.

The Thinness of the Coating

The PVD layer is extremely thin, often just a few microns. A major benefit of this is that it perfectly replicates the texture of the underlying stainless steel, whether it's a brushed, matte, or polished finish.

However, this also means that a deep scratch can potentially penetrate the entire coating and expose the steel underneath.

Why Texture Dictates Technique

Because the PVD coating follows the original texture, your cleaning method must respect it. Abrasives will create fine scratches that run against the grain of a brushed finish, permanently dulling the appearance.

The Recommended Cleaning Protocol

For over 99% of cleaning needs, a simple, three-step process is all that is required.

Step 1: Initial Wipe-Down

Start by wiping the surface with a dry, soft microfiber cloth. This removes loose dust and debris without grinding it into the finish.

Step 2: Gentle Washing

For fingerprints, oils, or grime, dampen a clean microfiber cloth with warm water and a few drops of mild, pH-neutral soap (like standard dish soap). Gently wipe the surface, following the grain if one is visible.

Do not apply heavy pressure. The soap and water are doing the work of breaking down the oils.

Step 3: Rinsing and Drying

Wipe the surface again with a separate, clean cloth dampened only with water to remove any soap residue.

Finally, and most importantly, dry the surface completely with another dry, soft cloth. This prevents water spots and mineral deposits from forming, which can be difficult to remove later.

What to Strictly Avoid

The durability of PVD can create a false sense of security. Damaging the finish is almost always a result of using the wrong tools or chemicals.

Abrasive Cleaners and Tools

Never use abrasive materials. This includes scouring pads, steel wool, gritty cleaning pastes, or powdered cleansers (like Comet or Bar Keepers Friend). These will inflict micro-scratches that will permanently mar the finish.

Harsh Chemical Agents

Avoid all harsh and acidic chemical cleaners. This includes bleach, ammonia-based cleaners (like Windex), oven cleaners, toilet bowl cleaners, and any solution containing strong acids or alkalis. These can chemically etch or discolor the PVD coating.

Stick to mild soap and water. If you are unsure about a cleaner, test it on a small, inconspicuous area first, but it is rarely worth the risk.

Stubborn Stains and Mineral Deposits

For stubborn hard water spots, a 50/50 solution of white vinegar and water can be effective. Apply it with a soft cloth, let it sit for no more than a minute, then rinse thoroughly with plain water and dry completely. Use this method sparingly.

Making the Right Choice for Your Goal

Your cleaning frequency and focus will depend on your objective.

- If your primary focus is daily maintenance: Simply wipe the surface with a dry or slightly damp microfiber cloth to remove fingerprints and dust.

- If your primary focus is a deep clean: Use the warm water and mild soap method, ensuring you rinse and dry thoroughly to prevent water spots.

- If your primary focus is preserving a high-polish finish: Be extra diligent about using only the softest microfiber cloths and drying immediately to prevent any mineral deposits from dulling the shine.

By treating the PVD surface with care, you will preserve its intended color and finish for years to come.

Summary Table:

| Cleaning Step | Recommended Tool/Material | Purpose & Key Tip |

|---|---|---|

| Initial Wipe | Dry microfiber cloth | Remove loose dust and debris without scratching. |

| Gentle Wash | Warm water & mild dish soap | Lift oils and grime; use light pressure and follow the grain. |

| Rinse & Dry | Clean water & dry microfiber cloth | Prevent water spots; thorough drying is critical. |

| Avoid | Abrasive pads, harsh chemicals (bleach, ammonia) | These will permanently scratch or discolor the PVD coating. |

Need equipment to create or test durable PVD coatings? KINTEK specializes in high-quality lab equipment and consumables for all your materials science and surface engineering needs. Our reliable tools help you achieve and maintain superior finishes. Contact our experts today to find the perfect solution for your laboratory!

Visual Guide

Related Products

- Evaporation Boat for Organic Matter

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- Stainless Steel Quick Release Vacuum Chain Three-Section Clamp

People Also Ask

- What is the widely used boat made of in thermal evaporation? Choosing the Right Material for High-Purity Deposition

- What temperature does evaporation occur? Unlock the Secrets to Controlling the Rate of Evaporation

- What were the 4 factors that affect the rate of evaporation? Master Control for Lab & Industrial Processes

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What is deposition in environmental chemistry? Understanding How Air Pollution Harms Ecosystems