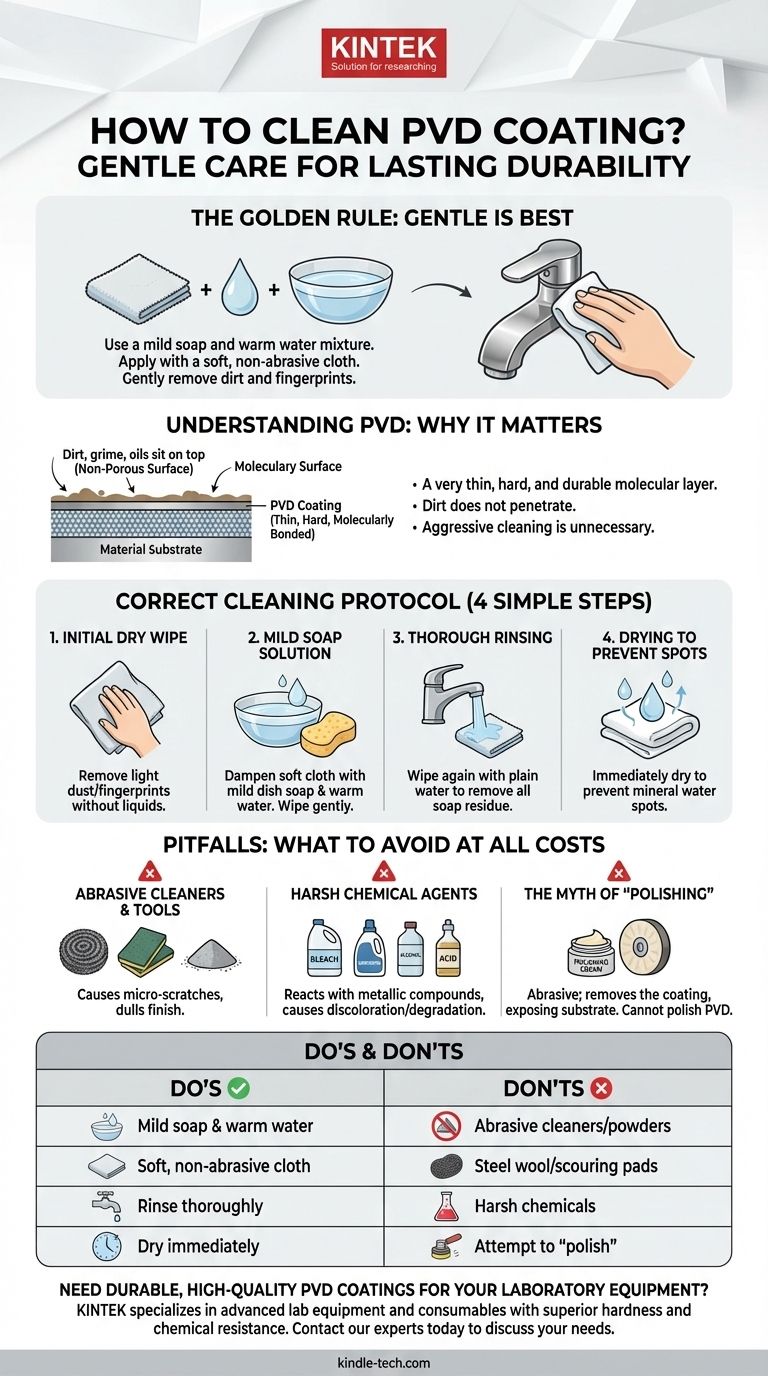

To clean PVD coatings effectively, use a simple mixture of mild soap and warm water applied with a soft, non-abrasive cloth. The goal is to gently remove dirt and fingerprints without using abrasive materials or harsh chemicals. This simple method preserves the integrity of the thin, durable finish, ensuring its longevity and appearance.

The exceptional durability of a PVD coating comes from its thin, hard, molecularly bonded layer. Therefore, the best cleaning approach is always the gentlest one, focused on protecting this layer from the two things that can damage it: physical abrasion and chemical attack.

What is PVD Coating and Why It Matters for Cleaning

To properly care for a PVD finish, it's essential to understand what it is. The manufacturing process itself dictates the best cleaning methods.

A Microscopic Layer of Durability

Physical Vapor Deposition (PVD) is a process performed in a high-vacuum environment where a solid metal is vaporized into a plasma. This vapor is then precisely deposited, molecule by molecule, onto the surface of a product, creating a very thin but extremely hard and durable coating.

This isn't a wet paint or a simple plating; it's a finish that is bonded to the substrate at a molecular level.

Non-Porous and Resilient

The PVD process creates a dense, non-porous surface. This means that dirt, grime, and oils tend to sit on top of the coating rather than penetrating it. This is why aggressive cleaning is rarely necessary.

The inherent resilience comes from the controlled application process, where factors like the coating material and pressure are managed to create a finish with specific characteristics like hardness.

The Correct Cleaning Protocol for PVD Surfaces

Follow these simple steps to ensure your PVD-coated items remain in pristine condition. This method is safe for all PVD finishes, from matte black to polished brass.

Step 1: Initial Dry Wipe

For light dust or fingerprints, a simple wipe with a clean, dry microfiber cloth is often sufficient. This removes surface contaminants without any liquids.

Step 2: Mild Soap Solution

If a dry wipe isn't enough, mix a few drops of mild dish soap into a bowl of warm water. Dampen a soft cloth or sponge in this solution, wringing out any excess water.

Gently wipe down the PVD surface to lift away any grime or residue.

Step 3: Thorough Rinsing

Using a separate clean cloth dampened with only plain water, wipe the surface again to remove any soap residue. Leaving soap to dry can create a film that dulls the finish.

Step 4: Drying to Prevent Spots

Immediately dry the item with a clean, soft, dry towel. This is a critical step to prevent water spots, which are mineral deposits left behind as water evaporates.

Understanding the Pitfalls: What to Avoid at All Costs

The most common way to damage a PVD finish is by using the wrong cleaning products. The coating's thinness makes it vulnerable to improper care.

Abrasive Cleaners and Tools

Never use abrasive cleaners, powders, or creams. These products contain small, hard particles designed to scrub away tough stains, but they will also scrub away the PVD finish over time, creating micro-scratches that dull its appearance.

Avoid using steel wool, scouring pads, or any abrasive brushes. Stick to soft cloths, such as microfiber.

Harsh Chemical Agents

Do not use cleaners containing acids, chlorine bleach, ammonia, or alcohol. These potent chemical agents can react with the metallic compounds in the PVD coating, potentially causing discoloration or degradation of the finish.

The Myth of "Polishing"

You cannot "polish" a PVD coating in the traditional sense. Polishes are, by nature, abrasive. Attempting to polish a PVD finish will only serve to remove it, exposing the substrate material underneath. The shine and color are integral to the coating itself.

How to Apply This to Your Product

Your cleaning strategy should be based on ensuring the long-term integrity of the finish, regardless of the item.

- If your primary focus is routine maintenance (e.g., faucets, fixtures): A weekly wipe-down with a soft cloth and mild soap and water is the perfect strategy to prevent buildup.

- If your primary focus is removing stubborn grime (e.g., tools, watches): Let a mild soap solution sit on the surface for a minute before wiping, but never resort to abrasive tools or chemicals.

- If your primary focus is long-term preservation: Always dry the surface completely after cleaning to prevent mineral deposits and maintain the original luster.

By treating the PVD finish with gentle care, you protect the advanced layer that gives your product its lasting beauty and durability.

Summary Table:

| Do's | Don'ts |

|---|---|

| Use mild soap & warm water | Use abrasive cleaners or powders |

| Wipe with a soft, non-abrasive cloth | Use steel wool or scouring pads |

| Rinse thoroughly with plain water | Use harsh chemicals (acid, bleach, ammonia) |

| Dry immediately with a soft towel | Attempt to 'polish' the coating |

Need Durable, High-Quality PVD Coatings for Your Laboratory Equipment? KINTEK specializes in advanced lab equipment and consumables, ensuring your tools have the resilient finishes they need to withstand demanding environments. Our PVD coating solutions offer superior hardness and chemical resistance, perfect for preserving your lab instruments. Contact our experts today to discuss how we can enhance your laboratory's capabilities with reliable, long-lasting products.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Custom CVD Diamond Coating for Lab Applications

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Cold Trap Direct Cold Trap Chiller

- Isostatic Molding Pressing Molds for Lab

People Also Ask

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What are the benefits of PECVD? Achieve Superior Low-Temperature Thin Film Deposition

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition