To definitively test for a CVD diamond, you must use advanced spectroscopic equipment found only in professional gemological laboratories. Because CVD diamonds are chemically and physically identical to natural diamonds, traditional tools like thermal probes or microscopes are insufficient for distinguishing them. The identification process relies on detecting subtle differences in crystal growth patterns and trace elements that are unique to the laboratory manufacturing process.

The core challenge in identifying a CVD diamond is that it is a real diamond. Therefore, testing isn't about finding a "fake," but about uncovering the evidence of its man-made origin story, which is invisible to the naked eye and requires sophisticated scientific analysis.

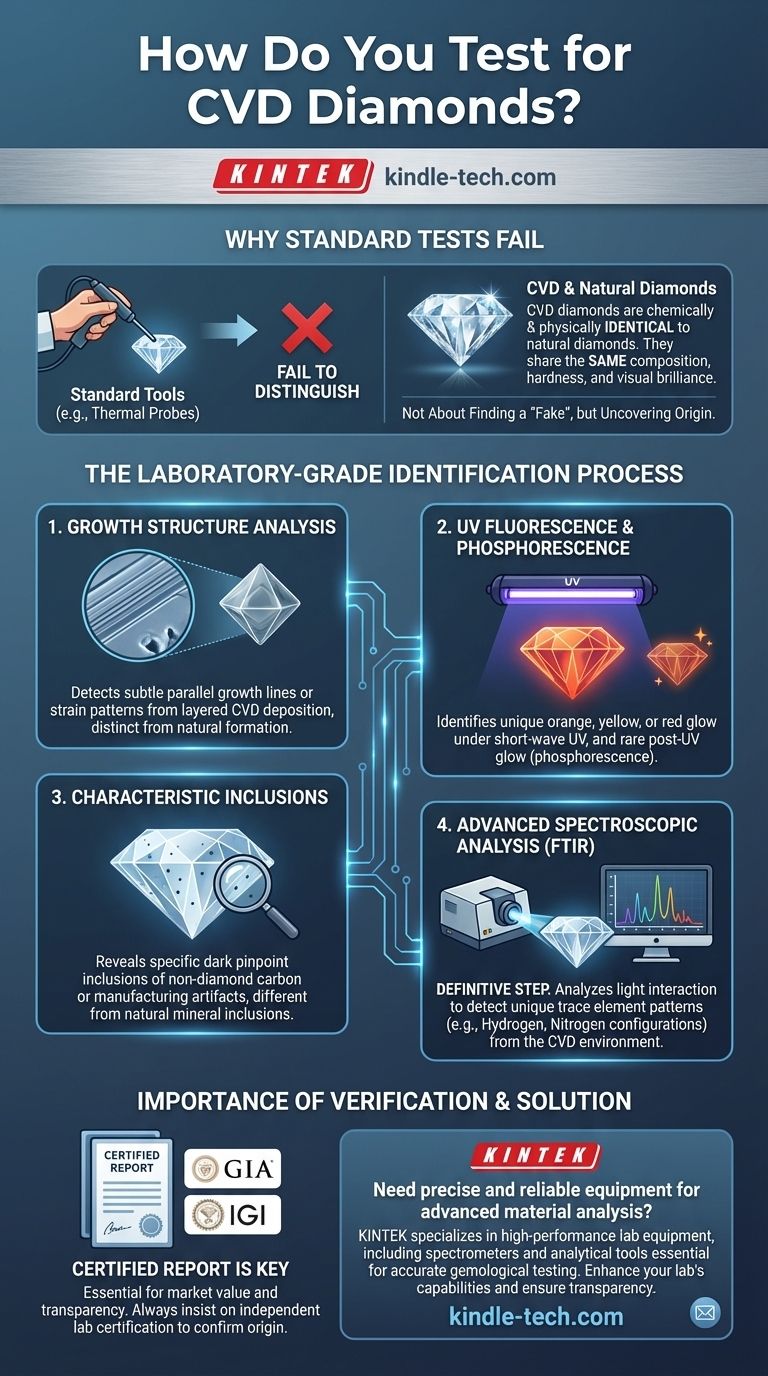

Why Standard Diamond Tests Fail

Standard tools used by jewelers are designed to differentiate diamonds from simulants like cubic zirconia or moissanite. They fail to distinguish between natural and lab-grown diamonds because their fundamental properties are the same.

Identical Chemical Composition

A CVD diamond is made of pure, crystallized carbon, just like a mined diamond. Its atomic structure is identical, giving it the same exceptional hardness and thermal conductivity that basic diamond testers are designed to detect.

Indistinguishable Visuals

To the eye, even a trained one with a loupe, a high-quality CVD diamond is visually indistinguishable from a natural one. Both exhibit the same fire, brilliance, and scintillation. While both can have inclusions, the identifying characteristics of these flaws require specialized magnification and analysis.

The Laboratory-Grade Identification Process

Gemological labs like the GIA (Gemological Institute of America) use a series of advanced tests to look for artifacts of the manufacturing process. The CVD method, which involves depositing carbon layers from a gas onto a diamond seed, leaves behind unique microscopic clues.

Telltale Growth Structure

Natural diamonds grow in octahedral (eight-sided) crystal structures over billions of years. CVD diamonds grow in thin layers in a single direction. This process can create subtle parallel growth lines, or strain patterns, that are not present in natural diamonds and can be seen under high magnification with specialized lighting.

Unique Fluorescence Signatures

When exposed to short-wave ultraviolet (UV) light, CVD diamonds often fluoresce in distinct colors, such as orange, yellow, or red, which are very rare in natural diamonds. Some may also exhibit phosphorescence, continuing to glow for a short period after the UV light is turned off, another strong indicator of a lab-grown origin.

Characteristic Inclusions

The CVD process is not perfect and can leave behind specific types of inclusions not found in nature. While natural diamonds may contain tiny crystals of other minerals, CVD diamonds can contain small, dark pinpoint inclusions of non-diamond carbon or other artifacts from the growth chamber.

Advanced Spectroscopic Analysis

This is the most definitive step. Spectrometers analyze how a diamond interacts with different forms of light and energy. Techniques like FTIR (Fourier Transform Infrared Spectroscopy) can detect the presence and configuration of elements like nitrogen and hydrogen within the crystal lattice, revealing patterns unique to the controlled CVD environment.

The Importance of Verification

The need for this rigorous testing comes down to two key factors: market value and transparency. While physically identical, the different origins and supply chains result in a significant price difference between natural and CVD diamonds.

The Role of Disclosure

Reputable sellers will always disclose that a diamond is laboratory-grown. Testing serves as a crucial verification step to ensure transparency and protect the consumer. An undisclosed lab-grown diamond is a misrepresentation.

The Power of Certification

For any significant diamond purchase, the most reliable way to confirm its origin is to have a grading report from a premier laboratory like GIA or IGI. This certificate will explicitly state if the diamond is "Laboratory-Grown" and serves as the ultimate proof of its identity.

Making the Right Choice for Your Goal

Understanding the origin of your diamond is essential for making an informed decision. The right approach depends on your specific role or objective.

- If your primary focus is purchasing a diamond: Always insist on a recent, independent grading report from a top-tier gemological laboratory that confirms the stone's origin.

- If your primary focus is selling or appraising diamonds: You must rely on professional lab services to verify any stones that lack clear certification or raise suspicion.

- If your primary focus is identifying a stone you already own: The only way to know its origin with 100% certainty is to submit it to a professional grading institution for a full analysis.

Ultimately, confidence in a diamond's identity comes not from a simple at-home test, but from verifiable and expert third-party certification.

Summary Table:

| Test Method | What It Detects | Why It's Effective |

|---|---|---|

| UV Fluorescence | Distinct orange, yellow, or red glow; phosphorescence | Rare in natural diamonds, common in CVD |

| Growth Structure Analysis | Parallel growth lines or strain patterns from layered growth | Natural diamonds grow in octahedral shapes |

| FTIR Spectroscopy | Trace elements like hydrogen or specific nitrogen configurations | Reveals unique patterns from the CVD process |

| Inclusion Analysis | Dark pinpoint inclusions of non-diamond carbon | Different from mineral inclusions in natural stones |

Need precise and reliable equipment for advanced material analysis? KINTEK specializes in high-performance lab equipment and consumables, including spectrometers and analytical tools essential for gemological and materials testing. Our solutions help laboratories ensure accuracy, transparency, and efficiency in identifying materials like CVD diamonds. Enhance your lab's capabilities — contact us today to discuss your specific needs!

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory CVD Boron Doped Diamond Materials

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- What are the advantages of using HFCVD for BDD electrodes? Scaling Industrial Diamond Production Efficiently

- How is something diamond coated? A Guide to CVD Growth vs. Plating Methods

- How does a Hot Filament Chemical Vapor Deposition (HFCVD) reactor function? Expert Guide to Diamond Film Fabrication

- How are reactants introduced into the reaction chamber during a CVD process? Mastering Precursor Delivery Systems

- How does PACVD equipment improve DLC coatings? Unlock Low Friction and High Heat Resistance