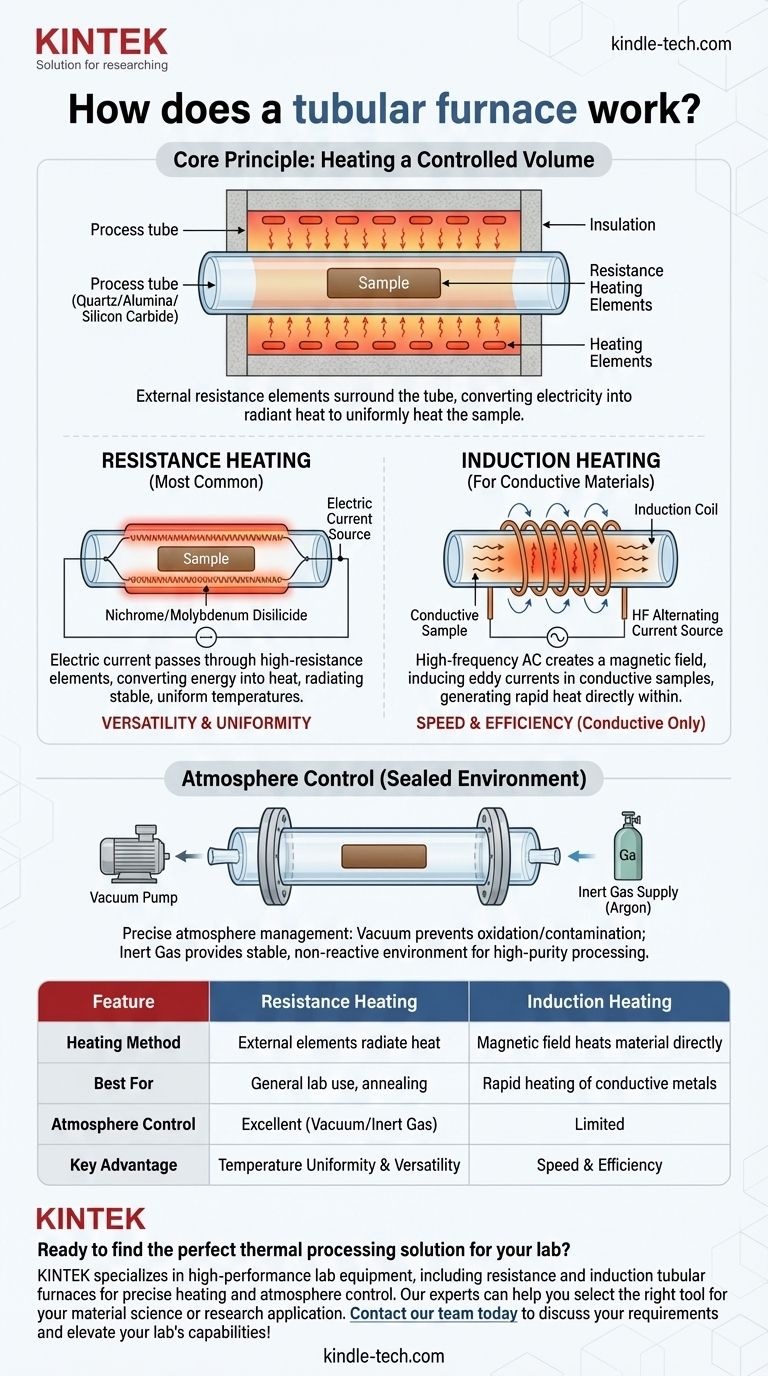

At its core, a tubular furnace is a high-temperature heating device defined by its cylindrical chamber. It works by creating a highly controlled thermal environment within this tube. The most common method involves external resistance heating elements that surround the tube, converting electricity into radiant heat that uniformly heats the sample placed inside.

A tubular furnace isn't a single type of technology, but rather a versatile form factor. Understanding that its "workings" depend entirely on the heating method it employs—most often resistance heating—is the key to selecting the right tool for a specific material processing task.

The Core Principle: Heating a Controlled Volume

To grasp how a tubular furnace operates, it's best to break it down into its two fundamental components: the tube itself and the heating system that surrounds it.

The Defining Feature: The Tube

The central element is the process tube, a hollow cylinder typically made from materials like quartz, alumina, or silicon carbide to withstand extreme temperatures. This tube serves as the chamber that holds the material or sample to be heated. Its enclosed, cylindrical shape is ideal for creating a uniform temperature zone and for controlling the internal atmosphere.

The Heating Mechanism: Creating the Thermal Environment

The "furnace" component consists of heating elements and insulation. These elements encircle the process tube without directly touching it. When activated, they generate intense heat that radiates inward, heating the tube walls and, in turn, the sample inside.

Common Heating Methods in Tubular Furnaces

While the tubular shape is constant, the method used to generate heat can vary significantly, which dictates the furnace's capabilities and applications.

Resistance Heating (The Most Common Method)

This method functions on the principle of resistance, similar to a muffle furnace or an electric stovetop. An electric current is passed through high-resistance heating elements (often made of materials like nichrome or molybdenum disilicide). These elements vigorously resist the flow of electricity, converting electrical energy directly into heat. This heat radiates through the insulation to the process tube, providing stable and highly uniform temperatures.

Induction Heating (For Conductive Materials)

A less common but powerful alternative is induction heating. In this design, a copper coil is wrapped around the process tube. A high-frequency alternating current is passed through this coil, creating a powerful, fluctuating magnetic field. This field induces electrical "eddy currents" directly within the conductive sample inside the tube. The material's own resistance to these internal currents generates rapid, intense heat from the inside out.

The Role of Atmosphere Control

The sealed nature of the process tube is a critical advantage. By fitting flanges on the ends, the internal environment can be precisely managed. A vacuum furnace operates by pumping out the air to create a low-pressure environment, which prevents oxidation and contamination of sensitive materials. Alternatively, an inert gas like argon can be flowed through the tube to provide a stable, non-reactive atmosphere for processing.

Understanding the Trade-offs

Each operational principle comes with distinct advantages and disadvantages that make it suitable for different tasks.

Resistance Furnaces: Versatility vs. Speed

The primary advantage of resistance heating is its versatility and temperature uniformity, making it the standard for lab research, annealing, and general-purpose heating. However, it can be slower to heat up and cool down compared to other methods.

Induction Furnaces: Speed vs. Material Limitation

Induction heating offers unparalleled speed, as it heats the material directly and almost instantly. Its major trade-off is that it only works with electrically conductive materials, limiting its application.

Atmosphere Control: Purity vs. Complexity

Operating under a vacuum or controlled atmosphere enables the high-purity processing of reactive materials. This capability comes at the cost of increased complexity and expense, requiring vacuum pumps, seals, and gas-handling systems.

Making the Right Choice for Your Goal

Selecting the right tubular furnace depends entirely on the material you are processing and your desired outcome.

- If your primary focus is general-purpose lab heating or annealing: A standard resistance-heated tubular furnace provides the best balance of temperature control, uniformity, and cost-effectiveness.

- If your primary focus is rapidly melting or heating conductive metals: An induction-heated system offers superior speed and efficiency for compatible materials.

- If your primary focus is processing air-sensitive or reactive materials: Prioritize a furnace system with robust vacuum and inert gas capabilities to ensure sample purity.

Understanding these core principles allows you to select not just a furnace, but the precise thermal processing tool your work demands.

Summary Table:

| Feature | Resistance Heating | Induction Heating |

|---|---|---|

| Heating Method | External elements radiate heat | Magnetic field heats material directly |

| Best For | General lab use, annealing | Rapid heating of conductive metals |

| Atmosphere Control | Excellent (Vacuum/Inert Gas) | Limited |

| Key Advantage | Temperature Uniformity & Versatility | Speed & Efficiency |

Ready to find the perfect thermal processing solution for your lab?

KINTEK specializes in high-performance lab equipment, including a wide range of tubular furnaces for precise heating, annealing, and atmosphere control. Whether you need the uniform heating of a resistance furnace or the rapid processing of an induction system, our experts can help you select the right tool for your material science or research application.

Contact our team today to discuss your requirements and elevate your lab's capabilities!

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

- Laboratory High Pressure Vacuum Tube Furnace

- Vertical Laboratory Tube Furnace

People Also Ask

- What is the role of corundum tubes in oxygen permeation testing? Ensure Integrity for Bi-doped Membranes

- Why is an Alumina Ceramic Tube Support Necessary for 1100°C Experiments? Ensure Data Accuracy and Chemical Inertness

- What is the function of alumina tubes and alumina wool in a pyrolysis furnace? Optimize Your Biochar Production Quality

- What are the advantages of using an alumina liner in a tube furnace for biomass combustion corrosion simulations?

- How do you clean a tube furnace tube? A Step-by-Step Guide to Safe and Effective Cleaning