In the landscape of plastics manufacturing, compression molding is frequently positioned as a more environmentally considerate option compared to alternatives like injection molding. Its core benefits stem from high material efficiency and lower energy demands during production. The process minimizes plastic scrap and is particularly effective for forming parts from recycled materials and natural fiber composites.

While no industrial process is entirely free of environmental impact, compression molding's primary advantage is its direct, low-waste design. By precisely placing material into a mold and avoiding the high-pressure channel systems of other methods, it fundamentally reduces both material scrap and energy consumption per part.

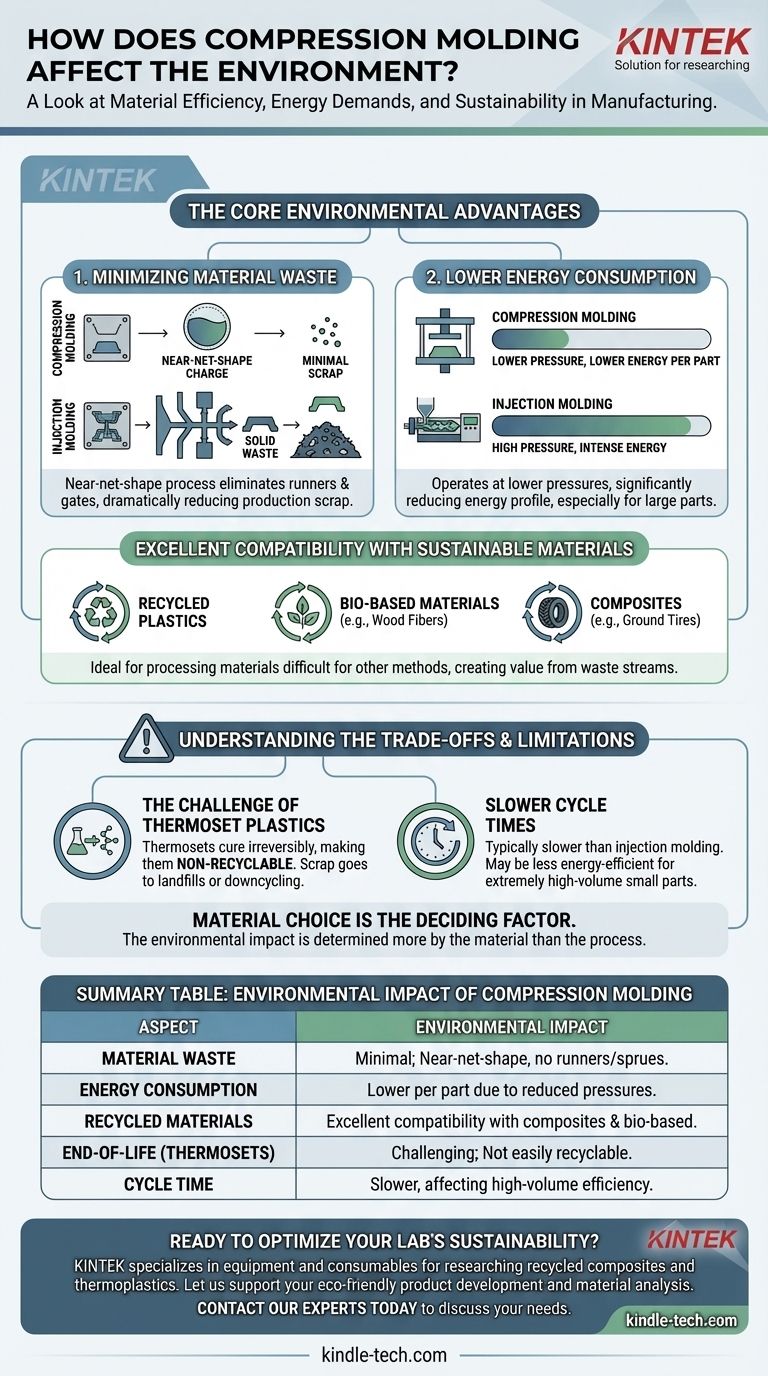

The Core Environmental Advantages

The environmental case for compression molding is built on two key pillars: efficiency in materials and efficiency in energy. These factors directly reduce the footprint of the manufacturing stage.

Minimizing Material Waste

Compression molding is a near-net-shape process. This means the initial amount of material, called the "charge," is weighed to be very close to the final part's required mass.

There are no runners, sprues, or gates—the channel systems used in injection molding to guide molten plastic into the cavity. These channels become solid plastic waste with every cycle, which is almost entirely eliminated in compression molding.

This dramatic reduction in production scrap means less wasted material, lower disposal costs, and a more efficient use of raw resources.

Lower Energy Consumption

The process generally operates at lower pressures than high-speed injection molding. It doesn't require the intense energy needed to force molten plastic through a complex network of narrow channels.

While heating is required to cure the material, the overall energy profile per part can be significantly lower. This is especially true for large, thick-walled components where injection molding would demand extremely high and sustained pressure.

Excellent Compatibility with Recycled & Bio-based Materials

Compression molding is exceptionally well-suited for working with materials that are difficult to process in other ways. This includes thermoset plastics, composites, and materials with a high percentage of fillers.

The process can easily incorporate recycled plastics, ground-up tires, wood fibers, and other bio-composites. This provides a valuable manufacturing outlet for waste streams, reducing landfill burden and decreasing the demand for virgin petroleum-based polymers.

Understanding the Trade-offs and Limitations

True objectivity requires acknowledging where the process falls short. The environmental benefits of compression molding are not absolute and come with critical trade-offs.

The Challenge of Thermoset Plastics

A significant portion of materials used in compression molding are thermosets (like epoxy, phenolic, or silicone). These materials undergo an irreversible chemical reaction (curing) when heated.

Once a thermoset part is cured, it cannot be re-melted and recycled in the same way as thermoplastics (like PET or Polypropylene). This creates a major end-of-life challenge, as scrap or post-consumer parts are destined for landfills or, at best, downcycling into low-grade filler.

Slower Cycle Times Can Add Up

Compression molding is typically a slower process than injection molding, with longer cycle times. For extremely high-volume production of millions of small parts, the faster cycles of injection molding might lead to greater overall energy efficiency at scale.

The energy savings of compression molding are most pronounced for medium-volume runs and for large, thick parts that are inefficient to produce with other methods.

Material Choice is the Deciding Factor

The environmental impact is ultimately dictated more by the material than by the process itself.

Using compression molding to form a part from a virgin, petroleum-based thermoset has a very different environmental profile than using the same process to create a part from a thermoplastic composite filled with recycled wood fiber. The process enables sustainable choices, but it does not guarantee them.

Making the Right Choice for Your Sustainability Goals

To apply this knowledge effectively, you must align the process capabilities with your specific environmental priorities.

- If your primary focus is minimizing production scrap: Compression molding is an exceptional choice due to its near-net-shape process that virtually eliminates runner and gate waste.

- If your primary focus is end-of-life recyclability: You must prioritize using thermoplastic materials rather than traditional thermosets, which are not recyclable.

- If your primary focus is incorporating recycled or bio-based content: The process excels at handling composites and filled materials, making it ideal for creating value from diverse waste streams.

Ultimately, leveraging compression molding for environmental benefit depends on a holistic strategy that aligns your material selection with the process's inherent efficiencies.

Summary Table:

| Aspect | Environmental Impact |

|---|---|

| Material Waste | Minimal; near-net-shape process eliminates runners and sprues. |

| Energy Consumption | Lower per part due to lower operating pressures. |

| Recycled Materials | Excellent compatibility with recycled plastics and bio-composites. |

| End-of-Life (Thermosets) | Challenging; thermoset parts are not easily recyclable. |

| Cycle Time | Slower than injection molding, affecting high-volume efficiency. |

Ready to optimize your lab's manufacturing processes for sustainability? KINTEK specializes in providing the right lab equipment and consumables to support your research into materials like recycled composites and thermoplastics. Whether you're developing new, eco-friendly products or need to analyze material properties, we have the solutions to help you achieve your sustainability goals. Contact our experts today to discuss how we can support your laboratory's needs.

Visual Guide

Related Products

- Small Injection Molding Machine for Lab Use

- Rubber Vulcanizer Vulcanizing Machine Plate Vulcanizing Press for Lab

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Electric Lab Cold Isostatic Press CIP Machine for Cold Isostatic Pressing

- Automatic Laboratory Heat Press Machine

People Also Ask

- What are the disadvantages of two plate mold? Key Limitations in Gating and Multi-Cavity Molding

- How to use a press mould? Master the Art of Consistent Ceramic Forms

- What is mold filling? Master the Critical First Step of Injection Molding

- What are the specific functions of graphite molds in the vacuum hot-press sintering process? Expert Insights for Ceramics

- Why are high-precision PTFE molds necessary for solid-state Li-S batteries? Ensure Structural Integrity & Performance

- What role does a high-strength steel mold play in the cold sintering of LLTO? Key to 600 MPa Densification

- What is the purpose of using a transparent polycarbonate mold? Visualizing the Anode Interface in ASSB Research

- What role does a stainless steel mold play during the hot-pressing of Li6PS5Cl? Achieve Precise Solid-State Densification