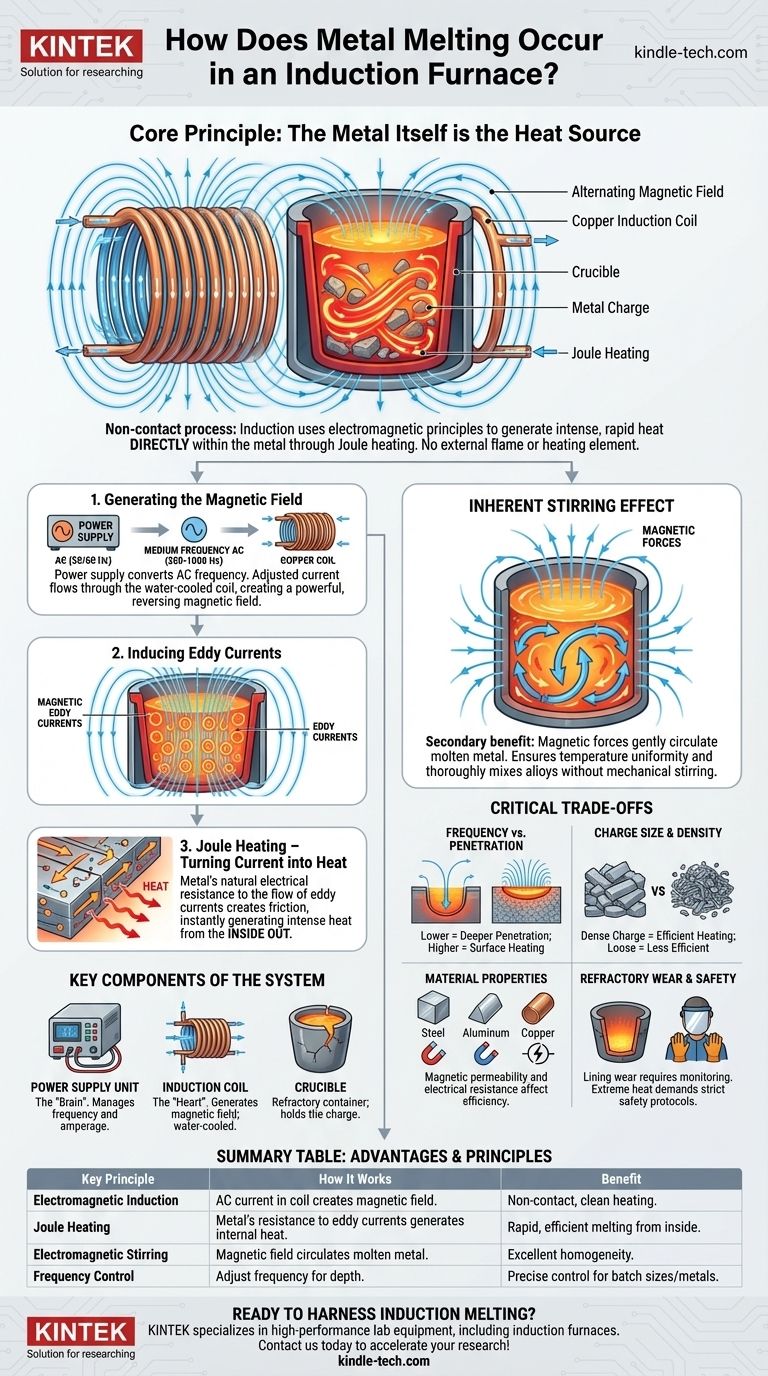

At its core, induction melting turns the metal itself into the heat source. An induction furnace uses a powerful, alternating magnetic field to induce electrical currents directly within the metal charge. The metal's natural resistance to these currents generates intense, rapid heat through a principle known as Joule heating, causing the metal to melt efficiently from the inside out without any external flame or heating element.

Unlike traditional furnaces that heat metal from the outside, induction melting is a non-contact process that uses electromagnetic principles to generate heat within the metal charge. This fundamental difference is the source of its speed, efficiency, and precise control.

The Physics of Induction: A Step-by-Step Breakdown

To understand how an induction furnace works, it's best to break the process down into its core physical principles. The entire operation relies on the relationship between electricity and magnetism.

Step 1: Generating the Magnetic Field

The process begins with a specialized power supply unit. This device converts standard mains electricity (e.g., 50/60 Hz) into an alternating current (AC) at a much higher or different frequency, typically in the medium-frequency range (300 Hz to 1000 Hz).

This adjusted current is then fed into a large, water-cooled copper coil that encircles a crucible containing the metal. As the AC flows through the coil, it generates a powerful and rapidly reversing magnetic field in the space within the coil.

Step 2: Inducing Eddy Currents

This powerful magnetic field passes directly through the metal placed inside the crucible. According to Faraday's Law of Induction, a changing magnetic field will induce an electrical current in any nearby conductor.

Because the metal charge is electrically conductive, the furnace's magnetic field induces numerous small, circular electrical currents within the metal. These are known as eddy currents.

Step 3: Joule Heating – Turning Current into Heat

The metal itself has a natural electrical resistance. As the induced eddy currents flow through the metal, this resistance creates friction and generates intense heat.

This phenomenon is called Joule heating. The heat is produced directly and instantly inside the metal, not transferred from an external source. This is what makes induction melting incredibly fast and efficient.

The Inherent Stirring Effect

A secondary benefit of the powerful magnetic field and eddy currents is an electromagnetic stirring action within the molten metal bath. This force gently circulates the liquid metal.

This natural stirring ensures excellent temperature uniformity and helps to mix alloys thoroughly, resulting in a more homogenous final product without the need for mechanical stirring.

The Key Components of an Induction Furnace System

An induction furnace is a system of components working in unison. Understanding each part clarifies its role in the overall process.

The Power Supply Unit

This is the "brain" of the operation. It manages the conversion of incoming power to the precise frequency and amperage needed to create the required magnetic field for a specific metal and charge size.

The Induction Coil

This is the "heart" of the furnace. It is almost always a hollow copper tube, formed into a coil, through which water is constantly circulated for cooling. It generates the magnetic field but does not get hot itself, other than from radiant heat from the melt.

The Crucible

This is the refractory container that holds the metal charge. It must withstand extreme thermal shock and high temperatures. Crucibles are typically made of materials like graphite, clay, or other specialized ceramics, chosen based on the type of metal being melted.

Understanding the Critical Trade-offs

While powerful, the induction process is governed by physical laws that create important trade-offs you must consider for optimal performance.

Frequency vs. Penetration Depth

The frequency of the alternating current is a critical variable. Lower frequencies penetrate deeper into the metal charge, making them ideal for melting large batches in large furnaces. Higher frequencies tend to concentrate heat near the surface, making them suitable for smaller melts or applications requiring rapid surface heating.

Charge Size and Density

The efficiency of the process depends on how well the metal charge "couples" with the magnetic field. A densely packed charge of solid metal pieces will heat far more efficiently than a loose collection of small shavings or turnings, which have significant air gaps.

Material Properties

Induction works on electrically conductive materials. However, the specific magnetic permeability and electrical resistance of the metal being melted will affect the heating rate and overall efficiency. Different metals require different power and frequency settings for optimal melting.

Refractory Wear and Safety

The intense heat and electromagnetic stirring action place significant stress on the crucible lining. This lining is a consumable part that requires regular inspection and replacement. Furthermore, the extreme temperatures demand strict safety protocols, including personal protective equipment (PPE) like face shields, heat-resistant gloves, and aprons.

How to Apply This to Your Goal

Your choice to use induction melting, and how you configure it, depends entirely on your objective.

- If your primary focus is rapid, clean melting of high-value alloys: Induction is ideal due to its speed and the absence of combustion byproducts, preventing contamination of the melt.

- If your primary focus is large-scale foundry production: The efficiency, speed, and natural stirring action of medium-frequency furnaces make them a superior choice for producing large volumes of iron and steel.

- If your primary focus is small-batch or laboratory work: The compact size, precise temperature control, and quick startup/shutdown times of high-frequency induction furnaces are perfectly suited for research and development.

By mastering these principles, you can leverage the distinct advantages of induction technology for nearly any metallurgical application.

Summary Table:

| Key Principle | How It Works | Benefit |

|---|---|---|

| Electromagnetic Induction | AC current in a coil creates a magnetic field that induces eddy currents in the metal. | Non-contact, clean heating process. |

| Joule Heating | The metal's resistance to eddy currents generates intense internal heat. | Rapid, efficient melting from the inside out. |

| Electromagnetic Stirring | The magnetic field naturally circulates the molten metal. | Excellent temperature and alloy homogeneity. |

| Frequency Control | Lower frequencies penetrate deeper; higher frequencies heat surface faster. | Precise control for different batch sizes and metals. |

Ready to harness the power of induction melting for your lab or production needs?

KINTEK specializes in high-performance lab equipment, including induction furnaces designed for precision, efficiency, and reliability. Whether you're melting high-value alloys in an R&D setting or require robust solutions for foundry production, our expertise ensures you get the right system for your specific metals and goals.

Contact us today to discuss how an induction furnace from KINTEK can accelerate your research, improve your product quality, and enhance your operational efficiency.

Visual Guide

Related Products

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Lab-Scale Vacuum Induction Melting Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- Does induction heating work with non magnetic materials? Yes, for conductive metals like aluminum and copper.

- What is the range of frequency for induction heating of machine use to melt metals without using fuel? Optimize Your Melting Process

- Will an induction heater melt aluminum? Yes, with the right high-frequency system.

- Can metal melt in a vacuum? Achieve Ultimate Purity for High-Performance Alloys

- Can you melt Aluminium in an induction furnace? Yes, and here's how to do it efficiently.

- How long do induction furnaces last? A Guide to Maximizing Your Furnace's Lifespan

- What is the primary function of a vacuum induction furnace in the preparation of silicon-containing T91 steel?

- What furnace is used for melting non-ferrous metals? Achieve High Purity with Induction Technology