In X-Ray Fluorescence (XRF) analysis, particle size is a critical variable that directly controls the accuracy and repeatability of your results. Inconsistent or overly large particles create a non-homogenous sample that introduces significant measurement errors. For pressed pellet analysis, the standard recommendation is to grind samples to a particle size below 50 micrometers (µm) to ensure the analytical surface is dense, uniform, and truly representative of the bulk material.

The core issue is that XRF is a surface-sensitive technique. The goal of sample preparation is not just to make particles small, but to create a perfectly homogeneous surface that eliminates physical inconsistencies, as these effects can distort the X-ray signal more than minor chemical variations.

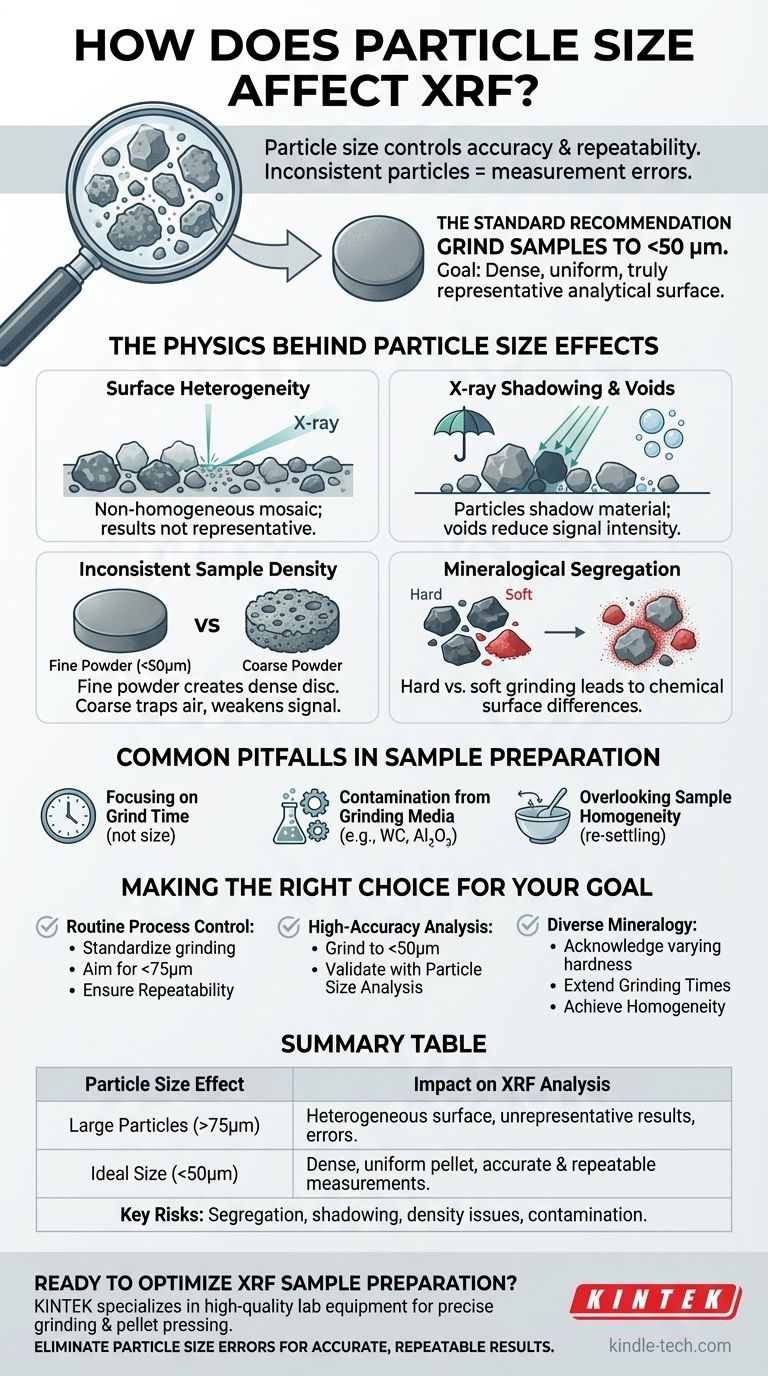

The Physics Behind Particle Size Effects

To understand why particle size is so influential, we must look at how the X-ray beam interacts with the sample. The analysis depth is very shallow, so the condition of the surface dictates the quality of the entire measurement.

The Problem of Surface Heterogeneity

XRF assumes the small area being analyzed is identical to the rest of your sample. If you have large particles of different minerals, the surface is a random mosaic. The X-ray beam might hit a particle rich in one element and miss another right next to it, leading to results that are not representative of the whole.

X-ray Shadowing and Voids

Imagine the X-ray beam as a steady rain. Large particles act like umbrellas, "shadowing" the material beneath them and preventing it from fluorescing. The gaps and voids between coarse, irregular particles also lower the effective density of the sample, reducing the overall signal intensity detected by the analyzer.

Inconsistent Sample Density

When creating a pressed pellet, fine powder (e.g., <50µm) compacts into a dense, uniform disc with a smooth, glass-like surface. Coarse powders resist compaction, trapping air and creating a less dense pellet with a rough surface. Since the XRF signal is proportional to the number of atoms in the beam's path, a low-density sample will produce an artificially weak signal.

Mineralogical Segregation

Different minerals within a single sample have different hardness and brittleness. During grinding, softer minerals may turn into a fine powder quickly, while harder minerals remain as larger particles. This can cause segregation, where the fine dust coats the larger grains, making the sample surface chemically different from the bulk material.

Common Pitfalls in Sample Preparation

Achieving the correct particle size is a process with its own set of challenges. Being aware of them is essential for producing reliable data.

Focusing on Grind Time, Not Particle Size

Different materials grind at different rates. Using a standardized grinding time for all sample types is a common mistake. The true goal is achieving a target particle size, which may require different durations or methods depending on the sample's physical properties.

Contamination from Grinding Media

The act of grinding is abrasive and can introduce contaminants into your sample. Grinding vials and media made of materials like tungsten carbide (WC) or alumina (Al₂O₃) can slightly wear down, adding trace amounts of tungsten, cobalt, or aluminum to your sample, which can lead to significant errors if you are analyzing for those elements.

Overlooking Sample Homogeneity

Even with fine particles, the sample must be thoroughly mixed before being pressed. During transport or handling, finer or denser particles can settle, re-introducing heterogeneity. Proper mixing is the final, critical step before analysis.

Making the Right Choice for Your Goal

To mitigate these effects, your sample preparation strategy must be deliberate, consistent, and aligned with your analytical needs.

- If your primary focus is routine process control: Standardize your grinding procedure (time, equipment, sample mass) and aim for a consistent particle size below 75µm to ensure high repeatability between measurements.

- If your primary focus is high-accuracy analysis (e.g., research or method development): Grind samples to less than 50µm and consider using techniques like particle size analysis to validate your preparation method for critical samples.

- If you are analyzing materials with diverse mineralogy: Acknowledge that hard and soft components will grind differently and extend grinding times to ensure the hardest phases are sufficiently reduced, which is key to achieving a truly homogeneous powder.

Ultimately, mastering particle size control is the foundation upon which all accurate and repeatable XRF analysis is built.

Summary Table:

| Particle Size Effect | Impact on XRF Analysis |

|---|---|

| Large Particles (>75µm) | Creates a heterogeneous surface, leading to unrepresentative results and significant measurement errors. |

| Ideal Size (<50µm) | Ensures a dense, uniform pressed pellet for accurate and repeatable measurements. |

| Key Risks | Mineral segregation, X-ray shadowing, inconsistent density, and potential contamination from grinding. |

Ready to optimize your XRF sample preparation and achieve superior analytical results?

KINTEK specializes in high-quality lab equipment and consumables for precise grinding and pellet pressing. Our solutions are designed to help you eliminate particle size errors, ensuring your XRF analysis is both accurate and repeatable.

Contact us today to discuss your specific laboratory needs and discover how we can support your success.

Get in touch with our experts now!

Visual Guide

Related Products

- Laboratory Jar Ball Mill with Alumina Zirconia Grinding Jar and Balls

- Laboratory Disc Cup Vibratory Mill for Sample Grinding

- Laboratory High Throughput Tissue Grinding Mill Grinder

- Laboratory Hybrid Tissue Grinding Mill

- Hybrid High Energy Vibratory Ball Mill for Lab Use

People Also Ask

- What is XRF sample preparation? Achieve Accurate and Reliable Elemental Analysis

- Which oil is used in hydraulic press machine? Choose the Right Fluid for Maximum Performance

- What is the purpose of a laboratory hydraulic press in FT-IR mineral analysis? Master Pellet Preparation

- How does continuous hydraulic pressure affect Ruthenium powder sintering? Control Microstructure & Crystal Alignment.

- What is the significance of using a laboratory hydraulic press for ceramic green bodies? Achieve Maximum Green Density

- Why is a laboratory hydraulic press used to compress powders into pellets? Enhance Solid-State Reaction Kinetics

- Why KBr is used for IR spectroscopy? The Ideal Medium for Solid Sample Analysis

- What is a major cause of hydraulic system and component failures? Prevent Costly Downtime with Clean Fluid