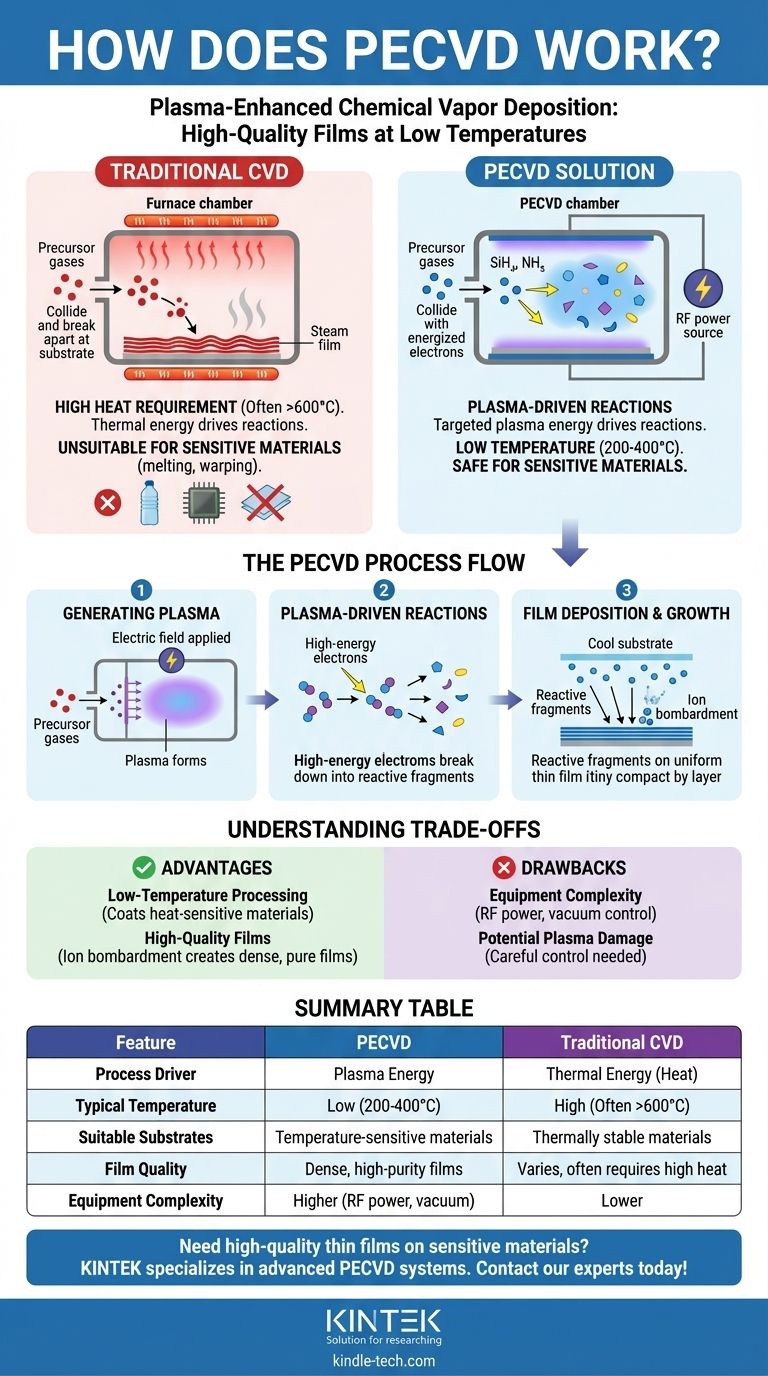

At its core, Plasma-Enhanced Chemical Vapor Deposition (PECVD) is a process used to deposit high-quality thin films onto a substrate without requiring extreme heat. It works by introducing precursor gases into a low-pressure chamber and then using an electric field to ignite a plasma, which provides the energy needed to drive the chemical reactions that form the film on the substrate's surface.

The fundamental advantage of PECVD is its ability to bypass the high-temperature requirements of traditional Chemical Vapor Deposition (CVD). By using an energy-rich plasma instead of heat, it allows for the creation of dense, pure films on materials that would otherwise be damaged or destroyed by a thermal process.

The Limitation of Traditional Deposition

To understand the value of PECVD, we must first look at its predecessor, conventional Chemical Vapor Deposition (CVD).

The High-Heat Requirement of CVD

In a traditional CVD process, a substrate is placed in a chamber and heated to very high temperatures, often several hundred degrees Celsius.

Precursor gases are then introduced into the chamber. The intense heat provides the thermal energy needed to break these gas molecules apart and trigger a chemical reaction on the substrate’s surface, resulting in a thin film.

The Problem with Heat

While effective, this reliance on high heat is a significant constraint. It makes traditional CVD unsuitable for depositing films on temperature-sensitive materials like plastics, polymers, or certain electronic components that would melt, warp, or degrade.

How PECVD Solves the Temperature Problem

PECVD was engineered specifically to overcome this thermal barrier. It achieves this by substituting brute-force heat with the targeted energy of a plasma.

Step 1: Generating the Plasma

The process begins by placing the substrate in a vacuum chamber. Precursor gases, such as silane (SiH₄) and ammonia (NH₃) for a silicon nitride film, are introduced at low pressure.

An electric field, typically radio frequency (RF), is then applied across electrodes in the chamber. This field energizes the gas, stripping electrons from the atoms and creating plasma—an ionized gas containing a mix of high-energy electrons, ions, and neutral radical species.

Step 2: Plasma-Driven Chemical Reactions

This plasma is the key to the process. The high-energy electrons collide with the precursor gas molecules, breaking them down into highly reactive chemical fragments.

Crucially, this dissociation happens because of the electron energy, not the ambient temperature of the chamber. The chamber itself can remain at a much lower temperature (e.g., 200-400°C) compared to traditional CVD.

Step 3: Film Deposition and Growth

These reactive fragments then travel to the comparatively cool substrate surface. Once there, they react and bond, gradually building up the desired thin film layer by layer.

For example, in solar cell manufacturing, this process is used to deposit a silicon nitride (SiNₓ) film that acts as an anti-reflection coating, improving the cell's efficiency.

Understanding the Trade-offs

While powerful, PECVD is not a universal solution. It involves a specific set of advantages and complexities that must be considered.

Advantage: Low-Temperature Processing

This is the primary benefit. PECVD opens up the possibility of coating a vast range of heat-sensitive materials that are incompatible with thermal CVD.

Advantage: High-Quality Films

The plasma environment offers another benefit: ion bombardment. As the film grows, it is constantly bombarded by ions from the plasma. This action compacts the film, leading to higher density and improved purity compared to some other low-temperature methods.

Drawback: Equipment Complexity

A PECVD system is more complex than a simple thermal CVD furnace. It requires RF or DC power supplies, impedance matching networks, and more sophisticated vacuum control to sustain a stable plasma, which can increase equipment and maintenance costs.

Drawback: Potential for Plasma Damage

While the low temperature prevents thermal damage, the high-energy ion bombardment can sometimes be a double-edged sword. If not carefully controlled, it can cause physical damage (sputtering) to the substrate or the growing film, or introduce stress.

Making the Right Choice for Your Application

Selecting the correct deposition technique depends entirely on the substrate material and the desired properties of the final film.

- If your primary focus is coating heat-sensitive substrates: PECVD is the definitive choice over high-temperature methods like thermal CVD.

- If your primary focus is achieving high film density at low temperatures: The ion-assisted deposition in PECVD provides a distinct advantage for creating robust, high-quality films.

- If your primary focus is cost minimization for thermally stable materials: Traditional thermal CVD may be a more straightforward and economical option if your substrate can withstand the high heat.

Ultimately, choosing PECVD is a strategic decision to enable high-performance coatings on materials that heat would otherwise forbid.

Summary Table:

| Feature | PECVD | Traditional CVD |

|---|---|---|

| Process Driver | Plasma Energy | Thermal Energy (Heat) |

| Typical Temperature | Low (200-400°C) | High (Often >600°C) |

| Suitable Substrates | Temperature-sensitive materials (e.g., polymers, electronics) | Thermally stable materials |

| Film Quality | Dense, high-purity films | Varies, but can require high heat for quality |

| Equipment Complexity | Higher (RF power, vacuum control) | Lower |

Need to deposit high-quality thin films on sensitive materials? KINTEK specializes in advanced lab equipment, including PECVD systems, to meet your specific research and production needs. Our solutions enable you to achieve superior film quality without the risk of thermal damage. Contact our experts today to discuss how we can support your laboratory's thin film deposition challenges!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

People Also Ask

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What is PECVD in semiconductor? Enable Low-Temperature Thin Film Deposition for ICs