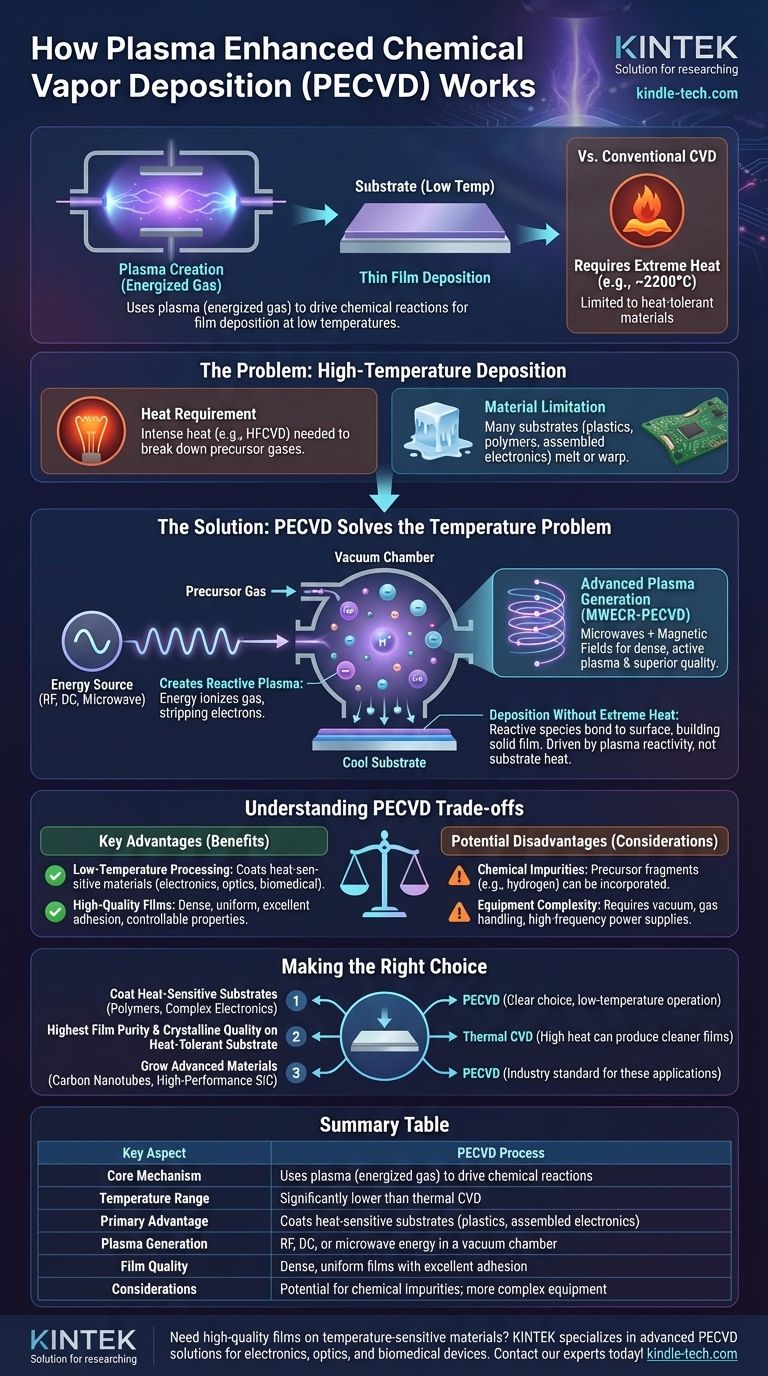

At its core, Plasma Enhanced Chemical Vapor Deposition (PECVD) uses an energized gas, or plasma, to deposit thin films onto a surface. Unlike conventional Chemical Vapor Deposition (CVD) which relies on extreme heat to trigger chemical reactions, PECVD initiates these reactions using energy from plasma. This allows high-quality films to be formed at significantly lower temperatures, making it a far more versatile process.

The central advantage of PECVD is its ability to create uniform, high-quality thin films without subjecting the target material to damaging high temperatures. It achieves this by using an electric or electromagnetic field to turn precursor gases into a reactive plasma, bypassing the need for thermal energy to drive the deposition process.

The Problem with High-Temperature Deposition

Traditional deposition methods, often grouped under the term thermal CVD, share a common requirement: intense heat. This creates a significant engineering constraint.

The Heat Requirement of Conventional CVD

Methods like Hot Filament CVD (HFCVD) use a filament heated to extreme temperatures (around 2200°C) to break down precursor gases. This thermal energy "cracks" the gas molecules, creating the reactive species needed to form a film on a nearby, cooler substrate.

The Resulting Material Limitation

This reliance on high heat severely limits the types of materials that can be coated. Many substrates, including plastics, polymers, and many assembled electronic components, would melt, warp, or be fundamentally damaged by the temperatures required for thermal CVD.

How PECVD Solves the Temperature Problem

PECVD fundamentally changes the equation by substituting electrical energy for thermal energy. It creates the necessary reactive chemistry without needing to heat the entire system to extreme temperatures.

Creating a Plasma State

The process takes place in a vacuum chamber. A specific precursor gas (the source for the film material) is introduced at low pressure. An energy source—typically radio frequency (RF), direct current (DC), or microwaves—is then applied.

This energy ionizes the gas, stripping electrons from atoms and creating a mixture of ions, electrons, radicals, and neutral particles. This energized, chemically reactive state is plasma.

Deposition Without Extreme Heat

The ions and highly reactive radical species within the plasma are chemically unstable. They readily react with any surface they contact.

When these reactive particles land on the substrate, they bond to its surface and to each other, building up a solid, uniform thin film. The reaction is driven by the chemical reactivity of the plasma, not by the thermal energy of the substrate.

Advanced Plasma Generation

More advanced techniques like Microwave Electron Cyclotron Resonance (MWECR-PECVD) use a combination of microwaves and magnetic fields. This traps electrons in a spiral path, dramatically increasing their collision rate with gas molecules and creating an exceptionally dense and active plasma, enabling superior film quality at very low temperatures.

Understanding the Trade-offs of PECVD

While powerful, PECVD is not a universal solution. Understanding its advantages and disadvantages is critical for proper application.

Key Advantage: Low-Temperature Processing

This is the defining benefit. PECVD enables the coating of temperature-sensitive materials that are incompatible with thermal CVD, opening up a vast range of applications in electronics, optics, and biomedical devices.

Key Advantage: High-Quality Films

PECVD processes can produce films that are dense, uniform, and have excellent adhesion. The ability to precisely control plasma parameters allows for fine-tuning of the film's properties, such as its structure and chemical stability.

Potential Disadvantage: Chemical Impurities

Because the plasma reactions are complex, precursor gas fragments can sometimes be incorporated into the growing film as impurities (e.g., hydrogen atoms). In some high-purity applications, this can be a drawback compared to the "cleaner" high-temperature environment of thermal CVD.

Potential Disadvantage: Equipment Complexity

A PECVD system requires a vacuum chamber, gas handling systems, and sophisticated high-frequency power supplies. This makes the equipment more complex and generally more expensive than some simpler deposition techniques.

Making the Right Choice for Your Application

Selecting the correct deposition method requires matching the process capabilities to your substrate material and desired film characteristics.

- If your primary focus is coating heat-sensitive substrates like polymers or complex electronics: PECVD is the clear and often only viable choice due to its low-temperature operation.

- If your primary focus is achieving the highest possible film purity and crystalline quality on a heat-tolerant substrate: A thermal CVD method may be a better option, as the high heat can produce cleaner, more ordered films.

- If your primary focus is growing advanced materials like carbon nanotubes or depositing high-performance SiC films: PECVD is a frequently used and highly effective industry standard.

Ultimately, PECVD empowers modern material science by providing a robust method to engineer surfaces without the destructive constraint of high heat.

Summary Table:

| Key Aspect | PECVD Process |

|---|---|

| Core Mechanism | Uses plasma (energized gas) to drive chemical reactions |

| Temperature Range | Significantly lower than thermal CVD |

| Primary Advantage | Coats heat-sensitive substrates (plastics, assembled electronics) |

| Plasma Generation | RF, DC, or microwave energy in a vacuum chamber |

| Film Quality | Dense, uniform films with excellent adhesion |

| Considerations | Potential for chemical impurities; more complex equipment |

Need to deposit high-quality thin films on temperature-sensitive materials? KINTEK specializes in advanced PECVD solutions and lab equipment for applications in electronics, optics, and biomedical devices. Our expertise ensures you get the right deposition process for your specific substrate and film requirements. Contact our experts today to discuss how our PECVD technology can enhance your research and production capabilities!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Multi Heating Zones CVD Tube Furnace Machine Chemical Vapor Deposition Chamber System Equipment

People Also Ask

- What are different types of thin films? A Guide to Function, Material, and Deposition Methods

- Can plasma enhanced CVD deposit metals? Why PECVD is rarely used for metal deposition

- Why does a PECVD vacuum system require both a rotary vane and turbo pump? Ensure High-Purity Coatings

- What is the difference between PECVD and APCVD? Choose the Right CVD Method for Your Application

- How do PECVD systems improve DLC coatings on implants? Superior Durability and Biocompatibility Explained