In short, Diamond-Like Carbon (DLC) coating is exceptionally durable for its intended purpose. It offers a level of hardness and scratch resistance that significantly surpasses traditional coatings like PVD or surface treatments like bluing. However, its durability is best understood as extreme resistance to wear and abrasion, not total indestructibility against all forms of damage.

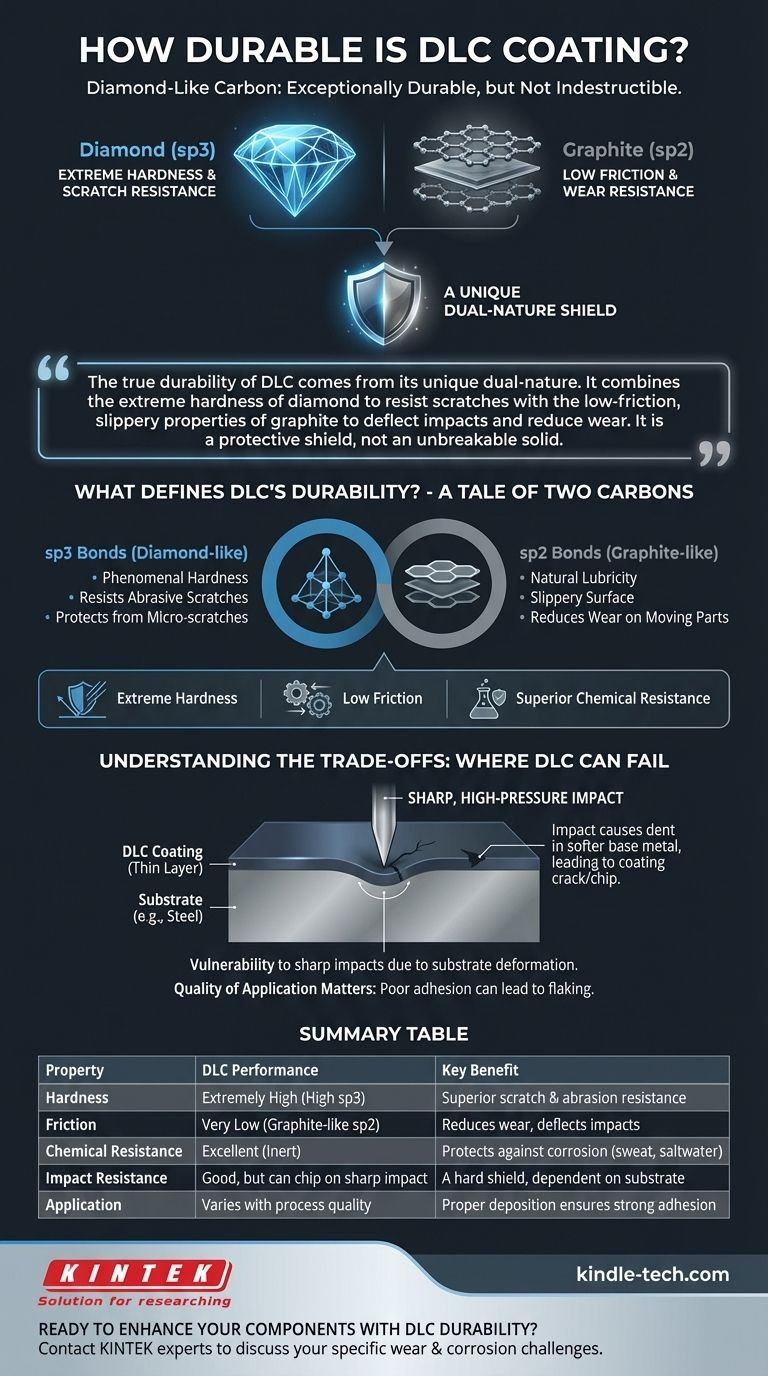

The true durability of DLC comes from its unique dual-nature. It combines the extreme hardness of diamond to resist scratches with the low-friction, slippery properties of graphite to deflect impacts and reduce wear. It is a protective shield, not an unbreakable solid.

What Defines DLC's Durability?

To understand how a DLC-coated item will perform, you need to look beyond a simple "strong or weak" label. Its resilience is a direct result of its atomic structure.

A Tale of Two Carbons

DLC is an amorphous coating composed of carbon atoms with two different types of bonds: sp3 and sp2.

The sp3 bonds are the same type found in natural diamond. This structure is what gives the coating its phenomenal hardness and resistance to abrasive scratches.

The sp2 bonds are the same type found in graphite. This structure provides a natural lubricity, or slipperiness, making the surface extremely low-friction.

Extreme Hardness for Scratch Resistance

The high ratio of diamond-like sp3 bonds makes a DLC surface incredibly hard. This is why a DLC-coated watch or knife blade can easily resist scuffs and scratches from daily contact with keys, zippers, or desks.

It protects the underlying metal from the kind of micro-scratches that accumulate over time and dull a finish.

Low Friction for Wear Resistance

The graphite-like sp2 bonds are just as important. This "slick" surface quality means that when an object scrapes against it, it is more likely to slide off harmlessly rather than dig in and cause a gouge.

This low coefficient of friction is also critical for internal components, where it drastically reduces wear between moving parts.

Superior Chemical and Corrosion Resistance

As a stable carbon layer, DLC is chemically inert. This provides a high-performance barrier against corrosive elements, including saltwater, sweat, and various chemicals. This ensures the finish and the metal beneath it remain protected.

Understanding the Trade-offs: Where DLC Can Fail

No coating is invulnerable. Trusting any material requires understanding its limitations. The "weakness" of DLC is a function of physics, not a flaw in the material itself.

It's a Coating, Not a Solid Material

The most critical factor to remember is that DLC is a very thin layer (typically a few microns thick) applied to a base metal like steel or titanium. The coating is only as stable as the material underneath it.

Vulnerability to Sharp, Direct Impacts

While DLC is extremely resistant to abrasive scratches, it can be compromised by a sharp, high-pressure impact. If you strike a DLC-coated watch hard against a sharp granite corner, the force can dent the softer steel underneath the coating.

Because the DLC layer is so rigid, it cannot stretch with the dented metal. This can cause the coating to crack or chip at the point of impact. Think of it like a thin layer of glass over a block of wood—the glass is hard, but a hammer blow will dent the wood and crack the glass.

The Quality of Application Matters

The durability of a DLC finish is highly dependent on the quality of the deposition process. Proper adhesion to the substrate is paramount. A poorly applied coating may be prone to flaking or peeling, even without significant impact. Reputable manufacturers use advanced plasma processes to ensure a strong, uniform bond.

Making the Right Choice for Your Goal

Ultimately, the decision to invest in a DLC-coated product depends on aligning its properties with your expectations.

- If your primary focus is daily wear and tear: DLC is an outstanding choice, offering best-in-class resistance to the scuffs, scratches, and corrosion that degrade most other finishes.

- If your primary focus is extreme, high-impact use: Understand its limits. While far tougher than the alternatives, a severe impact against a hard, sharp edge can still cause a chip where the underlying metal deforms.

- If your primary focus is long-term aesthetic stability: DLC is a premier option, as its chemically inert nature ensures the deep black finish will not fade, tarnish, or patina over time.

By viewing DLC as an ultra-hard, low-friction shield, you can accurately weigh its immense benefits against its physical limitations.

Summary Table:

| Property | DLC Coating Performance | Key Benefit |

|---|---|---|

| Hardness | Extremely High (High sp3 Bond Ratio) | Superior scratch and abrasion resistance |

| Friction | Very Low (Graphite-like sp2 Bonds) | Reduces wear on moving parts, deflects impacts |

| Chemical Resistance | Excellent (Chemically Inert) | Protects against corrosion from sweat, saltwater, chemicals |

| Impact Resistance | Good, but can chip on sharp, high-force impacts | A hard shield, dependent on substrate stability |

| Application | Varies with process quality | Proper plasma deposition ensures strong adhesion and durability |

Ready to enhance your components with the superior durability of a DLC coating?

At KINTEK, we specialize in advanced coating solutions for laboratory equipment and precision components. Our expertise ensures your parts benefit from maximum wear resistance, reduced friction, and long-lasting protection.

Contact our experts today to discuss how a DLC coating can solve your specific wear and corrosion challenges.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Glassy Carbon Sheet RVC for Electrochemical Experiments

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Hydrophilic Carbon Paper TGPH060 for Battery Lab Applications

People Also Ask

- Why is an RF plasma reactor used for reactive oxygen plasma etching tests? Evaluating Film Oxidation Resistance

- What role does a stainless steel bubbler play in RF-PECVD? Enhance Precursor Delivery for Siloxane Coatings

- What materials are deposited in PECVD? Discover the Versatile Thin-Film Materials for Your Application

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What are the advantages of using PECVD for CNT synthesis? Unlock High-Performance Photoelectrode Preparation

- What is the process of PACVD? Achieve High-Quality Coatings at Lower Temperatures

- What is plasma enhanced chemical vapor deposition PECVD equipment? A Guide to Low-Temperature Thin Film Deposition

- What is the difference between LPCVD SiN and PECVD SiN? Choose the Right Deposition Method for Your Device