In short, PVD is one of the most durable decorative finishes available today. Physical Vapor Deposition (PVD) creates a surface layer that is exceptionally hard, far exceeding traditional finishes like chrome plating. This hardness provides outstanding resistance to scratches, abrasion, and daily wear, while its chemical inertness protects against corrosion and color fading from UV light.

The true durability of a PVD finish comes not just from its hardness, but from the process itself. By bonding a thin film of metal alloys to a substrate at a molecular level, PVD creates a dense, non-porous surface that excels in resisting scratches, corrosion, and discoloration.

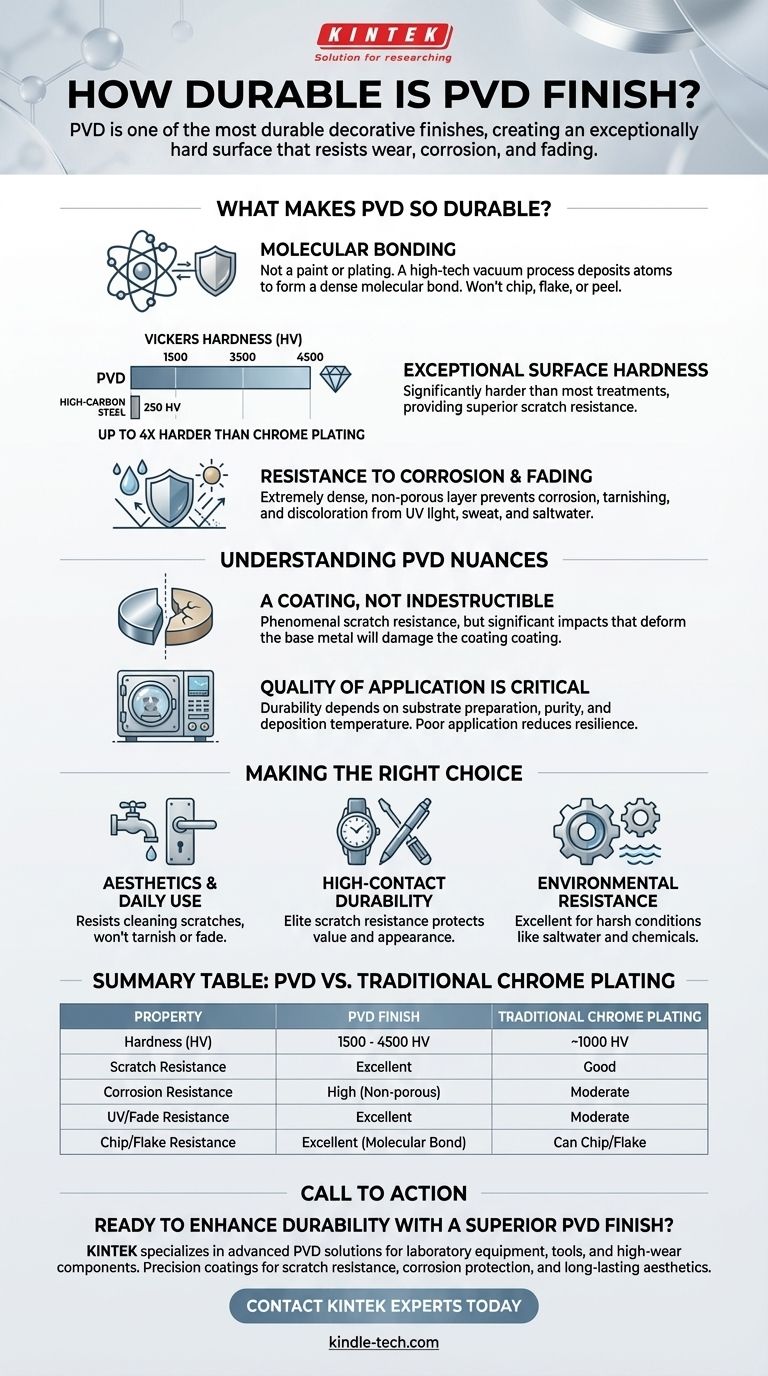

What Makes PVD So Durable?

To understand PVD's resilience, you have to look beyond a simple hardness number. Its durability is a result of the unique application process and the resulting material properties.

A Matter of Molecular Bonding

PVD is not a paint or a plating; it is a high-tech vacuum deposition process. A solid material is vaporized in a vacuum and deposited, atom by atom, onto the surface of the object.

This process creates a molecular bond between the coating and the substrate, resulting in a finish that won't chip, flake, or peel like a traditional paint or plating might.

Exceptional Surface Hardness

PVD coatings are significantly harder than most other surface treatments. On the Vickers hardness scale, PVD typically measures between 1500 and 4500 HV.

For comparison, high-carbon steel is around 250 HV, and hard chrome plating—itself a very durable finish—is around 1000 HV. This makes some PVD coatings up to four times harder than chrome, providing superior resistance to scratching.

Resistance to Corrosion and Fading

The PVD process creates an extremely dense and non-porous layer. This shield is chemically inert, preventing air, water, or other corrosive elements from reaching the base metal.

This is why PVD-coated items do not tarnish or discolor. They are highly resistant to damage from sweat, saltwater, and prolonged UV exposure, ensuring the color remains vibrant for years.

Understanding the Nuances of PVD

While PVD is incredibly robust, it's crucial to understand its limitations to have realistic expectations. It is a surface treatment, not a solid material.

Hardness vs. Wear Resistance

While PVD's high hardness contributes to its wear resistance, they are not the same thing. There is an optimal level of hardness for any application. An overly hard coating can become brittle.

The true performance comes from the combination of hardness, coating density, and adhesion to the substrate. Reputable manufacturers engineer their PVD formulas for a specific balance of properties.

It's a Coating, Not Indestructible

PVD provides phenomenal scratch resistance, but it cannot make the object itself indestructible.

If a PVD-coated item is struck with enough force to dent or deform the underlying base metal, the coating will be damaged along with it. It protects the surface from wear, not from significant physical impacts.

Quality of Application is Critical

Not all PVD coatings are created equal. The durability of the final product is highly dependent on the quality of the application process.

Factors like substrate preparation, vacuum chamber purity, and deposition temperature all play a critical role. A poorly executed PVD application will not deliver the expected longevity or resilience.

Making the Right Choice for Your Goal

PVD is often a superior choice, but its benefits are most pronounced in specific situations.

- If your primary focus is aesthetics and daily use: For items like faucets, door hardware, or kitchen fixtures, PVD offers a finish that will resist scratches from cleaning and handling, and it will not tarnish or fade over time.

- If your primary focus is high-contact durability: For watches, tools, or high-end pens, PVD provides elite scratch resistance that protects the item's appearance and value far better than uncoated or plated alternatives.

- If your primary focus is environmental resistance: For items exposed to harsh conditions like saltwater or chemicals, PVD's corrosion resistance is its most significant advantage, preventing degradation and maintaining structural integrity.

Ultimately, choosing a PVD finish is an investment in long-term surface integrity and appearance.

Summary Table:

| Property | PVD Finish | Traditional Chrome Plating |

|---|---|---|

| Hardness (HV) | 1500 - 4500 HV | ~1000 HV |

| Scratch Resistance | Excellent | Good |

| Corrosion Resistance | High (Non-porous) | Moderate |

| UV/Fade Resistance | Excellent | Moderate |

| Chip/Flake Resistance | Excellent (Molecular Bond) | Can Chip/Flake |

Ready to enhance your product's durability with a superior PVD finish? KINTEK specializes in advanced PVD coating solutions for laboratory equipment, tools, and high-wear components. Our precision coatings provide exceptional scratch resistance, corrosion protection, and long-lasting aesthetics. Contact our experts today to discuss how our PVD finishes can protect your investment and elevate your product's performance.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process