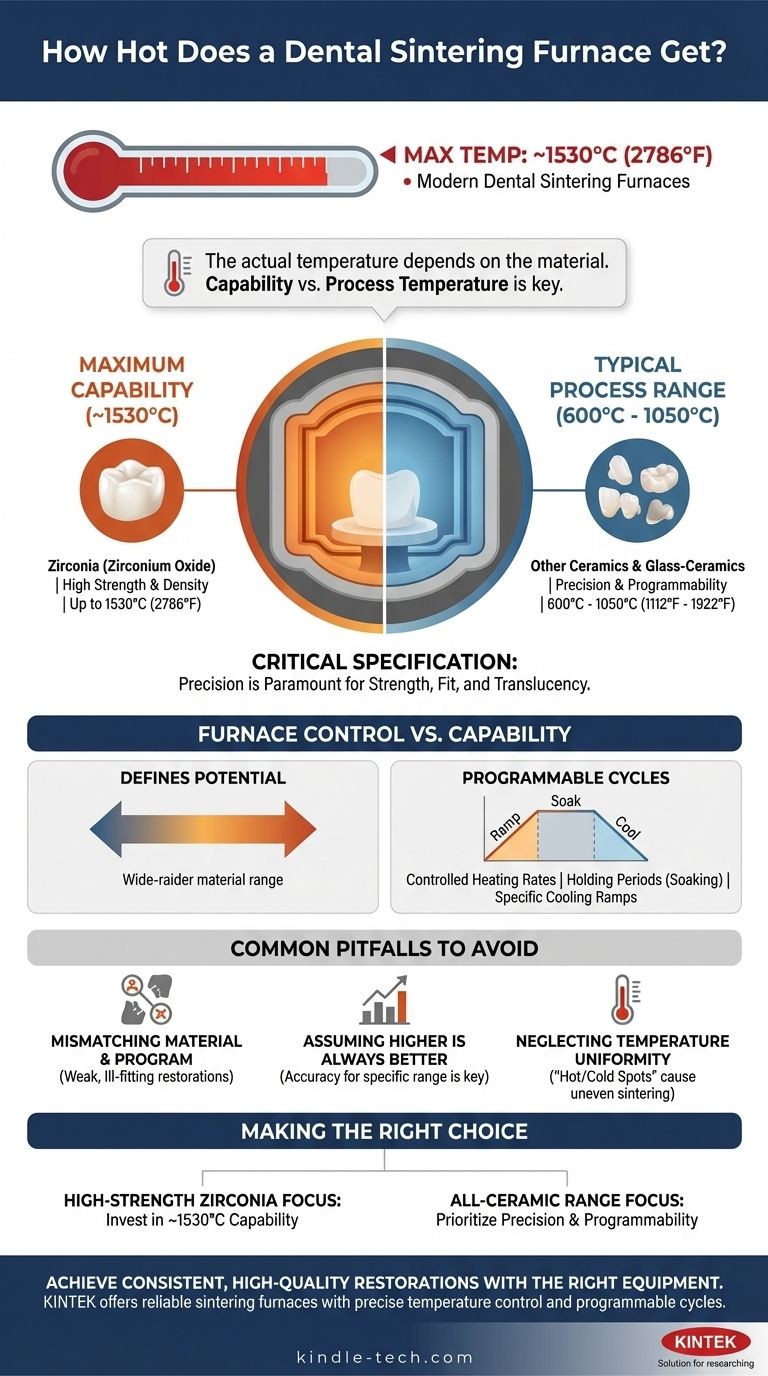

In short, a modern dental sintering furnace can reach a maximum temperature of around 1530°C (2786°F). However, the actual temperature used during a specific process depends entirely on the dental material being fired, with typical operating ranges falling between 600°C and 1050°C for many ceramics. The high maximum temperature is a measure of the furnace's capability, ensuring it can process the most demanding materials like zirconia.

The key is to distinguish between a furnace's maximum capability and the specific process temperature required by a material. While a furnace may be able to reach over 1500°C for zirconia, other materials require much lower, precisely controlled heat cycles.

Why Temperature Range is a Critical Specification

A dental furnace is not simply an oven; it is a precision instrument. The final strength, fit, and translucency of a dental restoration are directly determined by the accuracy of the temperature and the duration of the heating cycle, a process known as sintering.

The Demands of Zirconia

The need for high temperatures is primarily driven by zirconium oxide (zirconia), a popular material for crowns and bridges due to its exceptional strength.

To achieve its final, dense state, zirconia must be sintered at very high temperatures, often approaching the furnace's maximum limit of 1530°C. This process transforms the chalky, pre-sintered material into a robust, monolithic restoration.

The Needs of Other Ceramics

Many other dental materials, such as various glass-ceramics, do not require such extreme heat.

Their processing temperatures typically fall within a 600°C to 1050°C range. Using a temperature that is too high for these materials would ruin the restoration.

Understanding Furnace Control vs. Capability

A furnace's value is defined by both its peak temperature and its ability to execute precise heating programs.

Maximum Temperature Defines Potential

The maximum temperature rating tells you the full range of materials the furnace can handle. A higher ceiling provides more flexibility for a lab to adopt new and advanced materials in the future without needing new equipment.

Programmable Cycles Deliver Results

Sintering is not a simple matter of heating an object to a single temperature. It involves a carefully controlled sequence of steps.

Modern furnaces use programmable controllers that manage multi-stage cycles. A program can have multiple segments for controlled heating rates, holding periods (soaking), and specific cooling ramps, all of which are critical for a successful outcome.

Precision is Paramount

Features like touch screen controls, preset programs for specific materials, and internet connectivity are not just for convenience. They help ensure that these complex heating cycles are executed with precision and repeatability, minimizing errors and ensuring consistent quality.

Common Pitfalls to Avoid

Understanding the nuances of furnace temperature can help you avoid costly mistakes and inconsistent results.

Mismatching Material and Program

The most common error is using the wrong sintering program for a given material. Each manufacturer provides a specific temperature cycle for their materials; deviating from this can lead to weak, ill-fitting, or aesthetically poor restorations.

Assuming Higher is Always Better

A lab that exclusively works with lower-temperature ceramics does not necessarily need a furnace capable of 1530°C. While it provides future-proofing, the primary requirement is accuracy within the specific range needed for their daily work.

Neglecting Temperature Uniformity

A high maximum temperature is meaningless if the heat inside the chamber is not uniform. "Hot spots" or "cold spots" can cause uneven sintering, leading to internal stresses and potential failure of the final restoration.

Making the Right Choice for Your Goal

Selecting a furnace requires matching its capabilities to the materials you intend to use.

- If your primary focus is high-strength zirconia restorations: You must invest in a furnace capable of reaching at least 1530°C to ensure compatibility with all commercially available zirconia.

- If your primary focus is a wide range of all-ceramic materials: Prioritize a furnace with excellent programmable controls and proven temperature accuracy across a broad spectrum, even if its maximum temperature is slightly lower.

Ultimately, the right furnace is the one that can reliably and accurately execute the specific temperature cycles your chosen materials demand.

Summary Table:

| Material Type | Typical Sintering Temperature Range | Key Consideration |

|---|---|---|

| Zirconia (Zirconium Oxide) | Up to 1530°C (2786°F) | Requires the highest temperatures for maximum strength and density. |

| Other Ceramics & Glass-Ceramics | 600°C to 1050°C (1112°F to 1922°F) | Precision and programmability are critical to avoid damage. |

Achieve consistent, high-quality dental restorations with the right equipment.

Choosing a furnace with the correct temperature range and precision controls is essential for the strength, fit, and aesthetics of crowns and bridges. KINTEK specializes in lab equipment and consumables, serving dental laboratory needs with reliable sintering furnaces that offer precise temperature control and programmable cycles for both zirconia and other ceramics.

Let us help you find the perfect furnace for your materials and workflow. Contact our experts today to discuss your specific requirements and ensure flawless results for every restoration.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Dental Porcelain Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What is a porcelain furnace used for in dentistry? Precision Crafting for Lifelike Dental Restorations

- Is zirconia safe for teeth? Discover the Benefits of a Biocompatible, Durable Dental Material

- How do dental ceramic ovens process materials? Master Heat and Pressure for Perfect Restorations

- What are the advantages of porcelain crowns? Achieve a Natural, Beautiful Smile with Durable Restoration

- What does a dental furnace do? Achieve Perfect, Lifelike Dental Restorations

- What does sintering mean in dentistry? The Essential Process for Strong, Durable Restorations

- Are ceramic crowns stain-resistant? Discover the Secret to a Lasting, Bright Smile

- Why are high-precision vacuum sintering furnaces preferred over traditional methods for biofunctional dental ceramics?