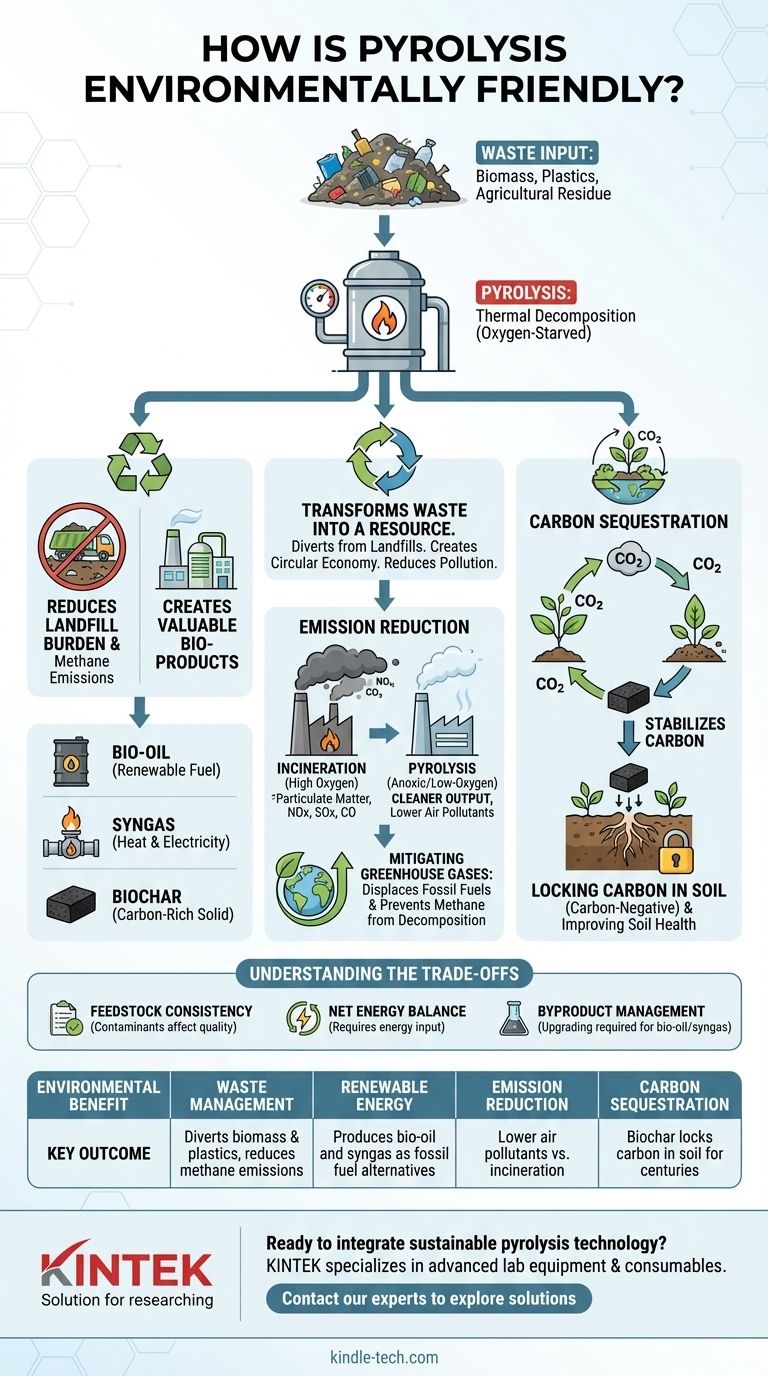

From an environmental standpoint, pyrolysis is a highly beneficial technology. It works by thermally decomposing organic materials like biomass, plastics, or agricultural residue in an oxygen-starved environment. This process diverts significant waste from landfills, creates renewable energy products, reduces harmful emissions compared to traditional combustion, and produces biochar, a stable material that can sequester carbon in the soil for centuries.

Pyrolysis is not merely a waste disposal method; it is a transformative process that redefines waste as a resource. Its core environmental advantage lies in its ability to create a more circular economy by recovering energy and materials, reducing pollution, and actively removing carbon from the atmosphere.

It Transforms Waste into a Resource

The most immediate benefit of pyrolysis is its role in waste management. It offers a constructive alternative to sending organic materials and plastics to landfills.

Reducing Landfill Burden

Pyrolysis can process a wide range of feedstocks, including agricultural residues, wood waste, and even certain plastics. By converting this material instead of burying it, pyrolysis reduces the demand for landfill space and mitigates the environmental issues associated with them, such as methane emissions and soil contamination.

Creating Valuable Bio-Products

The process breaks down complex organic materials into three primary products:

- Bio-oil: A liquid fuel that can be refined for use in engines and boilers, providing a renewable alternative to fossil fuels.

- Syngas: A mixture of combustible gases that can be used to generate heat and electricity, often to power the pyrolysis facility itself, making it highly energy-efficient.

- Biochar: A stable, carbon-rich solid that has significant environmental applications.

It Reduces Harmful Emissions

Unlike incineration, which burns waste with high levels of oxygen, pyrolysis heats material in an anoxic (oxygen-free) or low-oxygen environment. This fundamental difference leads to a much cleaner emissions profile.

Lowering Air Pollutants

The anoxic conditions prevent the formation of many pollutants commonly associated with combustion. Pyrolysis facilities produce significantly lower levels of:

- Particulate matter

- Nitrogen oxides (NOx)

- Sulfides (especially with low-sulfur biomass)

- Carbon monoxide (CO)

This cleaner output helps reduce air pollution and its associated health impacts.

Mitigating Greenhouse Gases

By creating renewable fuel from waste, pyrolysis displaces the need for fossil fuels, leading to a net reduction in greenhouse gas emissions. Furthermore, by diverting organic waste from landfills, it prevents the anaerobic decomposition that releases methane, a potent greenhouse gas.

It Enables Carbon Sequestration

Perhaps the most powerful environmental benefit of pyrolysis is its ability to create a "carbon-negative" energy loop through the production of biochar.

The Role of Biochar

During photosynthesis, plants capture atmospheric CO2. When this plant matter decomposes, that carbon is released back into the atmosphere. Pyrolysis stabilizes about 50% of this carbon into biochar, a charcoal-like substance that is extremely resistant to decomposition.

Locking Carbon in the Soil

When biochar is added to agricultural soil, it acts as a long-term carbon sink. This process, known as carbon sequestration, effectively locks carbon away for hundreds or even thousands of years. In addition to storing carbon, biochar also improves soil health, water retention, and nutrient delivery to plants.

Understanding the Trade-offs

While highly beneficial, pyrolysis is not a silver bullet. An objective assessment requires acknowledging its operational realities.

Feedstock Consistency and Purity

The efficiency and output of a pyrolysis system are highly dependent on the quality of its feedstock. Contaminants within the waste stream can affect the quality of the final products and may require pre-processing, adding complexity and cost.

Net Energy Balance

Pyrolysis requires a significant energy input to reach and maintain its high operating temperatures. A facility must be carefully designed to ensure that the energy produced from the syngas and bio-oil exceeds the energy consumed, resulting in a positive net energy balance.

Byproduct Management

The bio-oil produced can be acidic and require upgrading before it can be used as a drop-in fuel replacement. Likewise, syngas may need to be cleaned before it is combusted in an engine. These downstream processing steps are critical for realizing the full value of the products.

Applying Pyrolysis to Your Environmental Goals

The specific benefits you can leverage from pyrolysis depend on your primary objective.

- If your primary focus is waste management: Pyrolysis is an excellent technology for diverting organic and plastic waste from landfills, significantly reducing volume and converting a liability into valuable products.

- If your primary focus is renewable energy: It offers a consistent, dispatchable source of biofuels and electricity that can complement intermittent renewables like solar and wind.

- If your primary focus is carbon reduction: The production and soil application of biochar offers a direct, measurable, and long-term method for carbon sequestration, creating a pathway to carbon-negative operations.

Ultimately, pyrolysis provides a pragmatic and scientifically-proven pathway to a more circular and sustainable economy.

Summary Table:

| Environmental Benefit | Key Outcome |

|---|---|

| Waste Management | Diverts biomass & plastics from landfills, reducing methane emissions. |

| Renewable Energy | Produces bio-oil and syngas as alternatives to fossil fuels. |

| Emission Reduction | Lower air pollutants (NOx, particulates) vs. incineration. |

| Carbon Sequestration | Biochar locks carbon in soil for centuries, improving soil health. |

Ready to integrate sustainable pyrolysis technology into your operations? KINTEK specializes in advanced lab equipment and consumables for pyrolysis research and development. Whether you're focused on waste management, renewable energy, or carbon sequestration, our solutions help you optimize your process and achieve your environmental goals. Contact our experts today to explore how we can support your journey toward a circular economy.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Benchtop Laboratory Vacuum Freeze Dryer

People Also Ask

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- What are the reactions involved in pyrolysis of biomass? Unlock the Chemistry for Tailored Bio-Products