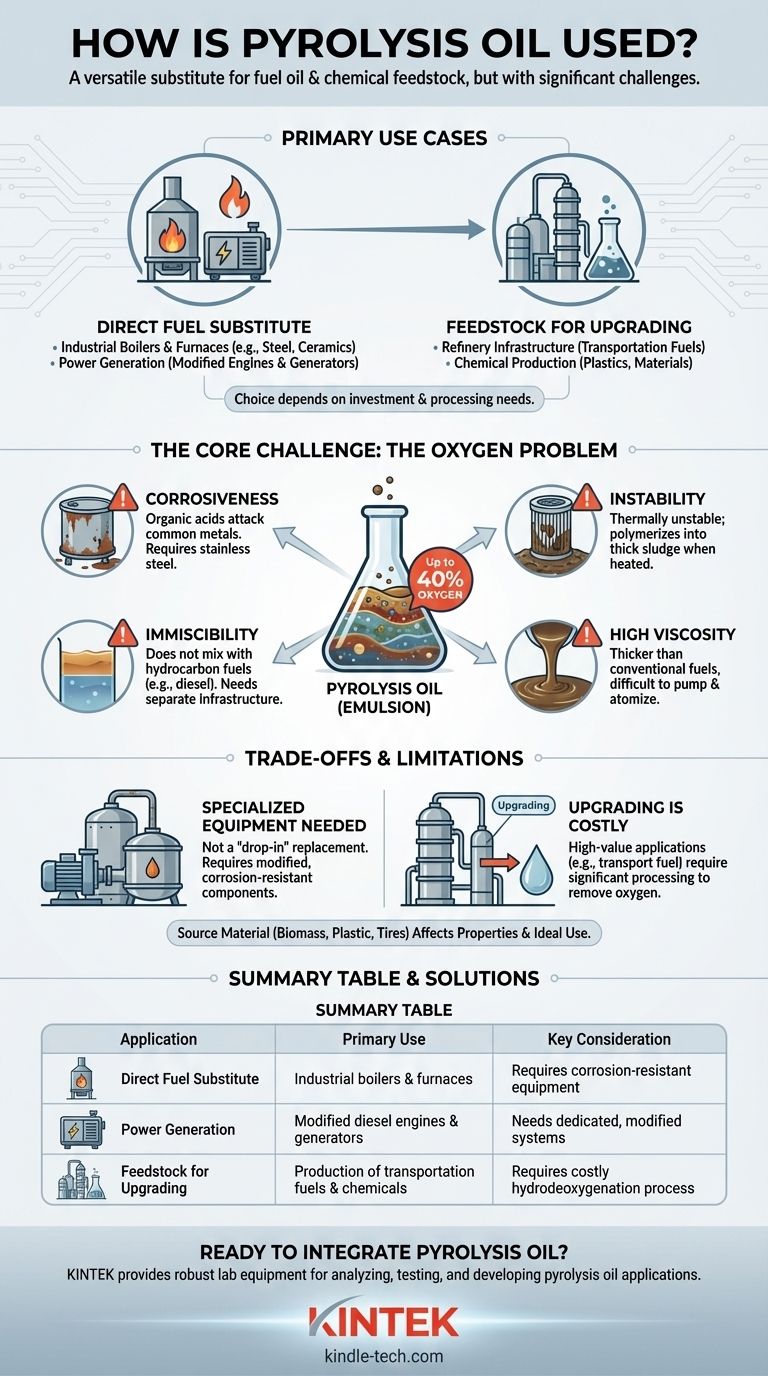

In principle, pyrolysis oil serves as a versatile substitute for conventional fuel oil and a feedstock for producing chemicals. It is most commonly used as a direct fuel for stationary applications like industrial boilers, furnaces, and power generation units. Beyond direct combustion, it can also be upgraded in refinery infrastructure to produce transportation-grade fuels or processed to extract valuable chemicals.

While pyrolysis oil presents a viable alternative to fossil fuels, its widespread adoption is constrained by its fundamental chemical nature. Its high oxygen content makes it corrosive, unstable, and incompatible with conventional fuel systems, meaning it cannot be treated as a simple "drop-in" replacement without significant modification or pre-treatment.

The Primary Use Cases for Pyrolysis Oil

The applications for pyrolysis oil fall into two main categories: direct use as a fuel and indirect use as a chemical feedstock. The choice depends heavily on the required investment in equipment and processing.

As a Direct Fuel Substitute

The most straightforward application is burning pyrolysis oil for heat or power. This is typically done in stationary systems rather than mobile engines.

It can be used as a substitute for conventional heating oils in industrial boilers and furnaces for industries like steel, iron, and ceramics. This usage is regulated by standards such as ASTM D7544 for performance specifications.

For Power Generation

Pyrolysis oil can be used as fuel in large, modified diesel engines and dedicated generators to produce electricity. This is a common strategy for converting waste materials (like tires or biomass) into a usable energy source on-site.

As a Feedstock for Upgrading

A more advanced application is to use pyrolysis oil as a raw material for producing higher-value products. It can be introduced into existing refinery infrastructure to be upgraded into conventional hydrocarbon fuels like gasoline and diesel.

It can also serve as a source for producing a wide range of specialty chemicals, plastics, and other materials.

The Core Technical Challenge: The Oxygen Problem

The primary barrier to using pyrolysis oil is its chemical composition, which is fundamentally different from petroleum crude oil. The key differentiator is its high oxygen content.

What Makes Pyrolysis Oil Different?

Pyrolysis oil is not a true oil in the petroleum sense. It is a complex liquid emulsion containing hundreds of different oxygenated organic compounds, polymers, and a significant amount of water.

This oil can contain up to 40% oxygen by weight, locked within compounds like acids (acetic acid), aldehydes (formaldehyde), phenols, and complex sugars.

The Impact of High Oxygen Content

This high oxygen content is the root cause of its most challenging properties:

- Corrosiveness: The presence of organic acids makes the oil highly corrosive to common metals like carbon steel, requiring specialized stainless steel storage tanks and components.

- Instability: The oil is thermally unstable. When heated, its compounds can react and polymerize, turning the liquid into a thick, unusable sludge that clogs filters and fuel lines.

- Immiscibility: It does not mix with hydrocarbon fuels like diesel or heating oil. This prevents simple blending and requires a dedicated and separate infrastructure.

- High Viscosity: Pyrolysis oil is often much thicker than conventional fuels, especially at lower temperatures, making it difficult to pump and atomize in burners.

Understanding the Trade-offs and Limitations

Using pyrolysis oil effectively requires acknowledging its inherent challenges and planning for them. It is not a simple "drop-in" solution.

The Need for Specialized Equipment

You cannot simply substitute pyrolysis oil for fuel oil in a standard system. Due to its corrosive and viscous nature, its use demands investment in modified equipment, including corrosion-resistant tanks, pumps, and fuel lines.

The Requirement for Upgrading

For high-value applications like creating transportation fuels, the oil is not usable in its raw form. It must first undergo a significant and costly upgrading process, such as hydrodeoxygenation, to remove the oxygen and stabilize the molecules.

The Source Material Matters

The specific properties of pyrolysis oil—and therefore its ideal use—depend heavily on the original feedstock. Oil derived from waste plastic will have different characteristics than oil from biomass or rubber tires, affecting its performance and potential applications.

Matching the Application to Your Goal

To deploy pyrolysis oil successfully, you must align your strategy with its chemical realities.

- If your primary focus is generating stationary heat or power: You can use raw pyrolysis oil, but you must invest in corrosion-resistant equipment and specialized fuel handling systems.

- If your primary focus is producing transportation fuels: Treat pyrolysis oil as a raw feedstock that requires a dedicated, multi-stage upgrading process to remove oxygen before it can be refined.

- If your primary focus is creating chemicals or new materials: View pyrolysis oil as a complex source of valuable oxygenated compounds, but recognize that separation and purification are significant chemical engineering challenges.

Understanding pyrolysis oil's unique chemistry is the key to navigating its challenges and unlocking its potential as a valuable resource.

Summary Table:

| Application | Primary Use | Key Consideration |

|---|---|---|

| Direct Fuel Substitute | Industrial boilers & furnaces | Requires corrosion-resistant equipment |

| Power Generation | Modified diesel engines & generators | Needs dedicated, modified systems |

| Feedstock for Upgrading | Production of transportation fuels & chemicals | Requires costly hydrodeoxygenation process |

Ready to integrate pyrolysis oil into your operations?

KINTEK specializes in providing the robust lab equipment and consumables necessary for analyzing, testing, and developing applications for pyrolysis oil. Whether you are researching its properties, upgrading it for fuel production, or handling it safely, we have the solutions to support your work.

Contact us today to discuss how our products can help you navigate the challenges and leverage the potential of pyrolysis oil. Get in touch now!

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Quartz Electrolytic Electrochemical Cell for Electrochemical Experiments

- Customizable PEM Electrolysis Cells for Diverse Research Applications

People Also Ask

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the different types of pyrolysis machines? Choose the Right System for Your Output