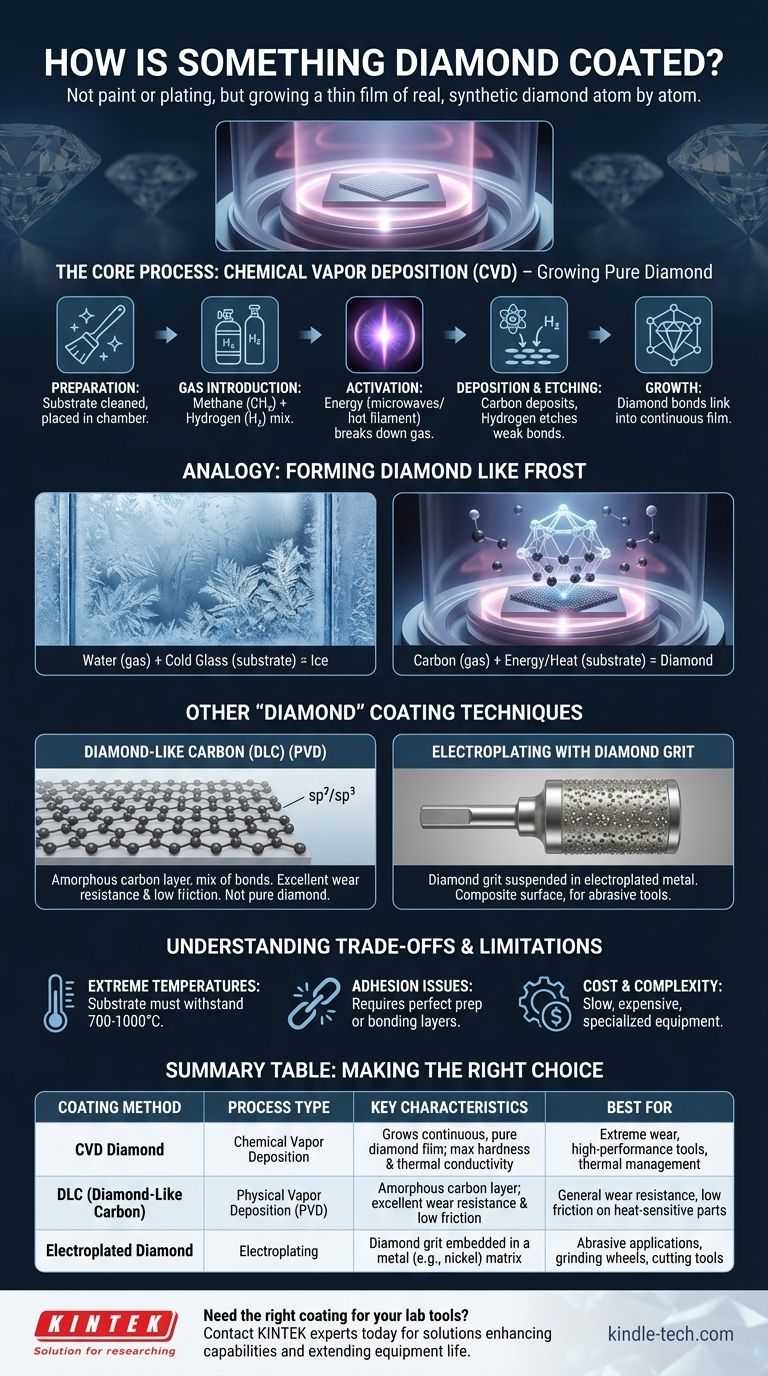

In short, diamond coating is not a paint or plating process in the traditional sense. It is a high-temperature, vacuum-based procedure where a thin film of real, synthetic diamond is literally grown, atom by atom, onto a substrate's surface from a carbon-containing gas.

The critical distinction to understand is that genuine diamond coating involves growing a layer of pure diamond via a process like Chemical Vapor Deposition (CVD). This is fundamentally different from lower-cost methods that either deposit a "Diamond-Like Carbon" (DLC) layer or embed diamond grit into a metal binder.

The Core Process: Chemical Vapor Deposition (CVD)

The vast majority of high-performance, continuous diamond films are created using Chemical Vapor Deposition (CVD). Think of this not as applying a coating, but as creating the perfect storm of conditions for diamond crystals to form and lock together on a surface.

How CVD Works: From Gas to Diamond

The process happens inside a sealed vacuum chamber.

- Preparation: The object to be coated (the substrate) is meticulously cleaned and placed inside the chamber.

- Gas Introduction: A precise mixture of gases is introduced. This is typically a carbon source gas (like methane, CH₄) diluted in a large amount of hydrogen gas (H₂).

- Activation: A significant amount of energy is applied to the gas. This energy, usually from microwaves or a hot filament, breaks the gas molecules apart into highly reactive atoms and radicals.

- Deposition: These reactive carbon atoms deposit onto the hotter substrate. The hydrogen atoms play a crucial role by selectively etching away any carbon atoms that form weaker graphite bonds (sp²), leaving only the carbon atoms that form ultra-strong diamond bonds (sp³).

- Growth: Over hours, these diamond bonds link up to form a continuous, polycrystalline diamond film that is structurally identical to natural diamond.

Analogy: Forming Diamond Like Frost

Imagine frost forming on a cold windowpane on a humid day. Water molecules from the air (the "gas") land on the cold glass (the "substrate") and, under the right conditions, arrange themselves into structured ice crystals.

CVD is a highly advanced version of this. It uses carbon-containing gas and precisely controlled energy to ensure the atoms arrange themselves not into ice, but into the strongest crystal structure known: diamond.

Other "Diamond" Coating Techniques

The term "diamond coated" is used broadly and can refer to other processes that are very different from CVD. It is essential to know the difference.

Diamond-Like Carbon (DLC)

Often applied using Physical Vapor Deposition (PVD), DLC is not pure diamond. It is an amorphous layer of carbon with a mix of both diamond (sp³) and graphite (sp²) bonds.

DLC coatings are extremely hard, slick, and wear-resistant, but they do not possess the supreme hardness or thermal conductivity of a true CVD diamond film. They are, however, more versatile and can be applied at lower temperatures.

Electroplating with Diamond Grit

This is a more mechanical process. Fine particles of diamond dust (grit) are suspended in a liquid electroplating bath, typically containing nickel.

As the nickel metal is electrically plated onto the substrate, it traps and binds the diamond particles to the surface. This does not create a continuous film but rather a composite surface of diamond grit held in a metal matrix. This method is common for abrasive tools like grinding wheels and cutting discs.

Understanding the Trade-offs and Limitations

Choosing to use a diamond coating requires understanding its significant practical constraints.

Substrate and Temperature Limits

True CVD diamond growth requires extremely high temperatures, often between 700-1000°C (1300-1830°F). This means the substrate material must be able to withstand this heat without melting, warping, or losing its structural properties. This rules out many steels, aluminum alloys, and all plastics.

Adhesion is the Weakest Link

The bond between the diamond film and the substrate is a common point of failure. Without perfect surface preparation and, often, the use of intermediate bonding layers, a diamond coating can chip or flake off under mechanical stress or thermal shock.

Cost and Complexity

CVD is a slow, expensive, and highly technical process requiring specialized vacuum equipment and expert oversight. This is why true diamond-coated tools are a premium product, reserved for applications where the performance benefits justify the cost.

Making the Right Choice for Your Application

The right "diamond" coating depends entirely on your performance goal and budget.

- If your primary focus is maximum hardness, tool life in extreme conditions, or thermal management: You need a true polycrystalline diamond film, which is applied via Chemical Vapor Deposition (CVD).

- If your primary focus is low friction and broad wear resistance, especially on heat-sensitive parts: A Diamond-Like Carbon (DLC) coating is a more versatile and cost-effective choice.

- If your primary focus is aggressive material removal or grinding: An electroplated coating with embedded diamond grit is the standard and most economical solution.

Understanding the difference between growing a film, depositing a layer, and embedding grit is the key to selecting a coating that truly delivers the performance you require.

Summary Table:

| Coating Method | Process Type | Key Characteristics | Best For |

|---|---|---|---|

| CVD Diamond | Chemical Vapor Deposition | Grows a continuous, pure diamond film; maximum hardness & thermal conductivity | Extreme wear, high-performance tools, thermal management |

| DLC (Diamond-Like Carbon) | Physical Vapor Deposition (PVD) | Amorphous carbon layer; excellent wear resistance & low friction | General wear resistance, low friction on heat-sensitive parts |

| Electroplated Diamond | Electroplating | Diamond grit embedded in a metal (e.g., nickel) matrix | Abrasive applications, grinding wheels, cutting tools |

Need the right coating for your lab tools or components?

At KINTEK, we specialize in advanced lab equipment and consumables, including high-performance coating solutions. Whether you're developing cutting-edge tools or require components with superior wear resistance, our expertise can help you select and implement the ideal coating technology for your specific application.

Contact our experts today to discuss how our solutions can enhance your laboratory's capabilities and extend the life of your critical equipment.

Visual Guide

Related Products

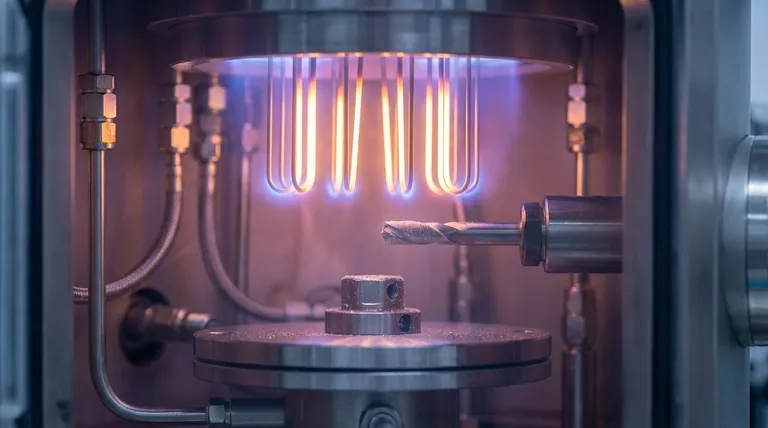

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Laboratory CVD Boron Doped Diamond Materials

- CVD Diamond Domes for Industrial and Scientific Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

People Also Ask

- What is the difference between physical and chemical Vapour deposition techniques? Choose the Right Coating Method for Your Application

- Why is Chemical Vapor Deposition (CVD) equipment utilized in the manufacturing of high-rate carbon nanotube films?

- What are the key differences between CVD and PVD? Choose the Best Thin Film Deposition for Your Lab

- What is pyrolysis in the context of single-layer graphene manufacturing? Overcoming the 1000°C Thermal Barrier

- What is the role of a controlled atmosphere reactor in the synthesis of nano-carbon-cement? Master CVD Nanotech

- What are the advantages of coating using sputtering technique? Superior Film Quality & Material Versatility

- How are high-temperature reaction furnaces used in the coating of regenerated graphite for improved anode performance?

- What are the methods of chemical vapour deposition? A Guide to APCVD, LPCVD, and PECVD