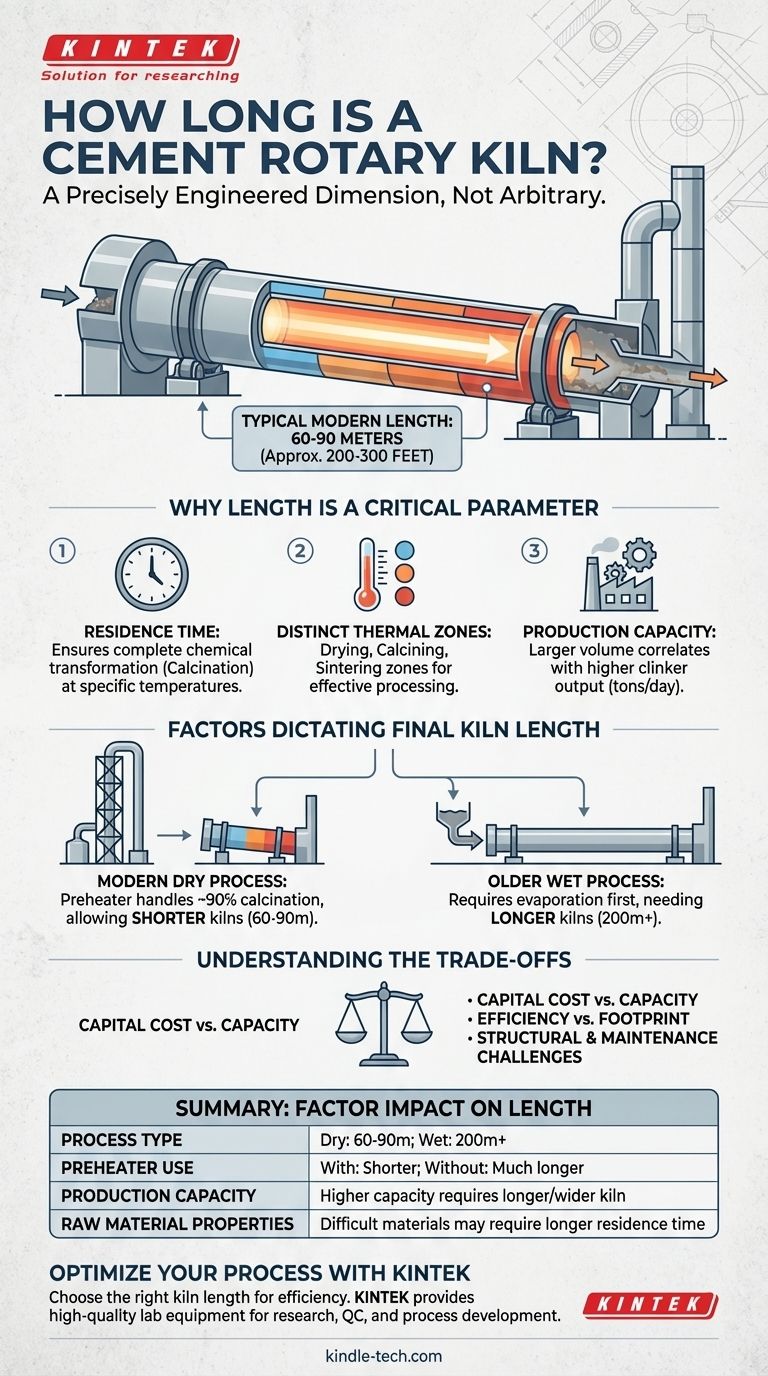

To be direct, a modern cement rotary kiln typically ranges from 60 to 90 meters (approximately 200 to 300 feet) in length. However, this dimension can vary significantly based on the specific process technology and the plant's production capacity.

A rotary kiln's length is not an arbitrary specification but a carefully engineered dimension dictated by the required residence time for chemical reactions, the plant's production capacity, and overall thermal efficiency.

Why Kiln Length is a Critical Design Parameter

The length of a kiln is fundamental to its function, which is to heat raw materials like limestone and clay to about 1,450°C (2,640°F) to create cement clinker. The kiln's dimensions are engineered to control this complex chemical and thermal process perfectly.

The Importance of Residence Time

For the raw materials to undergo the necessary chemical transformation (a process called calcination), they must remain inside the kiln at specific temperatures for a set amount of time. This is known as residence time.

A longer kiln provides greater control over this residence time, ensuring the reactions are complete before the material exits.

The Need for Distinct Thermal Zones

A rotary kiln is not uniformly hot. It is designed to have several distinct zones: a drying and preheating zone, a central calcining zone, and a final sintering zone.

The kiln's length provides the physical space required to establish a stable and effective temperature gradient across these zones, ensuring each stage of the process happens correctly.

Impact on Production Capacity

The volume of a kiln, determined by its length and diameter, directly correlates with its production capacity.

A longer and wider kiln can process a greater volume of raw material per hour, resulting in a higher output of cement clinker, measured in tons per day.

Factors That Dictate Final Kiln Length

The "typical" 60-90 meter length applies mostly to modern dry-process plants. The exact specification is a result of several interdependent factors.

Preheater and Precalciner Technology

This is the single most important factor in modern plant design. Most new facilities use a multi-stage preheater tower and a precalciner that heat the raw material before it even enters the kiln.

This pre-processing handles up to 90% of the calcination outside the kiln, allowing the kiln itself to be much shorter, more efficient, and focused only on the final, highest-temperature sintering stage.

The "Wet" vs. "Dry" Process

Older "wet process" plants, which feed the raw material as a slurry, required extremely long kilns—sometimes exceeding 200 meters (650 feet). This extra length was needed to first evaporate all the water before the heating process could begin.

Modern "dry process" plants are far more thermally efficient and use the shorter kilns that are now standard.

Raw Material Characteristics

The specific chemical makeup and moisture content of the limestone, clay, and other components influence how they behave when heated.

Materials that are harder to process may require a slightly longer residence time, which can influence the final design length of the kiln system.

Understanding the Trade-offs

Choosing a kiln length is an engineering decision that balances performance with cost and complexity.

Capital Cost vs. Capacity

A longer kiln requires significantly more steel, concrete for foundations, and expensive, heat-resistant refractory bricks for its lining. The initial investment cost is a primary constraint.

Efficiency vs. Footprint

While modern, short kilns paired with preheaters are highly efficient, the entire system (including the tall preheater tower) has a very large vertical footprint. This is a trade-off against the massive horizontal footprint of older, long-kiln designs.

Structural and Maintenance Challenges

An extremely long kiln is a massive, rotating piece of machinery that must be perfectly aligned on its support piers to prevent sagging or mechanical failure. Longer kilns introduce greater complexity in both structural engineering and ongoing maintenance.

How to Interpret Kiln Dimensions

The length of a cement kiln is best understood as one component of a larger, integrated system.

- If your primary focus is plant design: See kiln length as a variable dependent on the preheating technology. A shorter kiln almost always implies the presence of a highly efficient preheater/precalciner tower.

- If your primary focus is production capacity: View kiln length and diameter together as the primary drivers of a plant's potential output in tons per day.

- If your primary focus is process efficiency: Recognize that shorter, modern kilns are not less capable but are in fact markers of a more thermally efficient and advanced cement production process.

Ultimately, a rotary kiln's length is a precise answer to a complex equation of chemistry, thermodynamics, and economic efficiency.

Summary Table:

| Factor | Impact on Kiln Length |

|---|---|

| Process Type (Dry vs. Wet) | Dry process: 60-90m; Wet process: 200m+ |

| Preheater/Precalciner Use | With preheater: Shorter; Without: Much longer |

| Production Capacity | Higher capacity requires longer/wider kiln |

| Raw Material Properties | Difficult materials may require longer residence time |

Optimize Your Cement Production Process with KINTEK

Choosing the right kiln length is critical for maximizing your plant's efficiency, output, and profitability. The engineering decisions involved are complex, balancing chemistry, thermodynamics, and cost.

KINTEK specializes in providing high-quality laboratory equipment and consumables essential for researching and optimizing these industrial processes. Whether you are developing new materials, testing raw feedstocks, or monitoring clinker quality, our reliable lab solutions support the innovation driving the cement industry forward.

Let KINTEK be your partner in precision. Contact our experts today to discuss how our equipment can enhance your research, quality control, and process development efforts.

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Laboratory Jaw Crusher

People Also Ask

- What is the process of pyrolysis to produce biochar? A Guide to Controlled Thermal Decomposition

- How do you calculate the cost of firing an electric kiln? Master Your Studio's Energy Expenses

- How fast is pyrolysis? A Guide to Controlling Process Speed for Your Desired Product

- What is pyrolysis of lignocellulosic materials? Converting Biomass into Bio-oil, Bio-char, and Syngas

- What is a furnace for firing pottery called? Discover the Kiln: Your Key to Perfect Ceramics

- What are the distinct regions within the material bed during the rolling mode of motion? Optimize Mixing Efficiency

- What type of process is calcination? A Guide to Precise Thermal Decomposition

- How much energy is needed for pyrolysis? Achieve a Self-Sustaining Operation