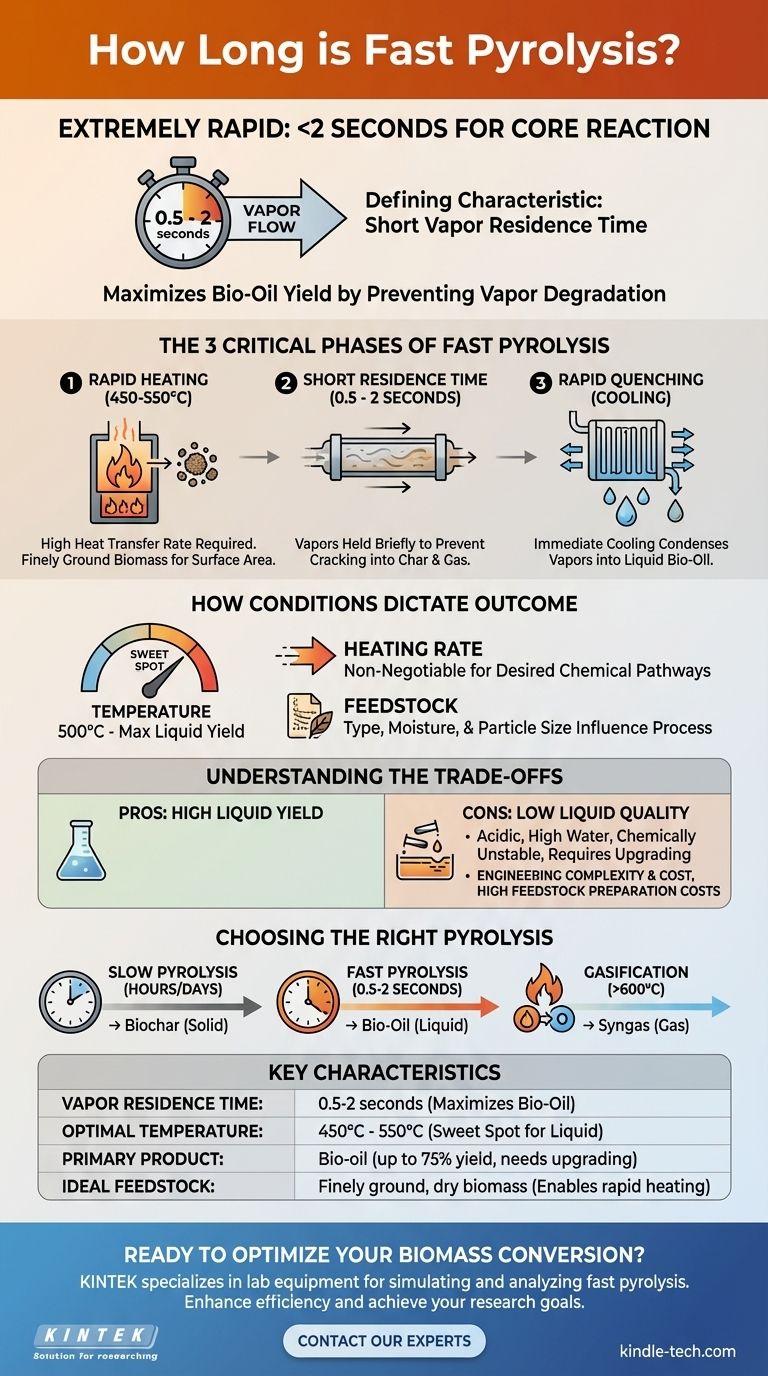

Fast pyrolysis is an extremely rapid process, with the core chemical reaction completing in less than 2 seconds. This short vapor residence time is a defining characteristic, essential for maximizing the yield of liquid bio-oil by preventing it from further degrading into non-condensable gases and char.

The defining feature of fast pyrolysis is not just its speed, but the purpose of that speed: to rapidly heat biomass and then immediately quench the resulting vapors. This strategy maximizes liquid bio-oil yield by preventing valuable intermediate products from breaking down into less desirable char and gas.

The Core Principles of Fast Pyrolysis

To understand "how long" the process is, you must understand the three critical time-dependent phases that define it: rapid heating, short residence time, and rapid cooling.

The Critical Role of High Heat Transfer

Before the reaction can even begin, the biomass feedstock must be brought to the target temperature (typically 450-550°C) almost instantaneously.

This requires very high heat transfer rates, which is why fast pyrolysis reactors often use finely ground biomass to maximize surface area and ensure every particle heats up quickly and uniformly.

The Importance of Short Vapor Residence Time

This is the direct answer to your question. The hot vapors produced from the decomposing biomass are kept at the reaction temperature for a very brief period, typically between 0.5 and 2 seconds.

This short duration is a deliberate engineering choice. It provides just enough time for the biomass to break down into the molecular precursors of bio-oil, but not long enough for these valuable vapors to undergo secondary reactions (or "crack") into permanent gases and additional solid char.

Rapid Quenching to Capture the Liquid

Immediately following the short residence time, the hot vapors must be cooled down (quenched) very quickly.

This rapid cooling condenses the vapors into a liquid product known as bio-oil or pyrolysis oil. Failing to quench quickly would allow the undesirable secondary reactions to continue, defeating the purpose of the short residence time.

How Process Conditions Dictate the Outcome

The precise duration and temperature profile of the process are carefully controlled to steer the chemical outcome. The yield and properties of the final bio-oil depend heavily on these process conditions.

Temperature's Effect on Product Yield

The temperature determines which products are favored. Fast pyrolysis operates in a "sweet spot" around 500°C that maximizes liquid yield.

Lower temperatures and much longer times (slow pyrolysis) favor solid char production. Much higher temperatures favor the production of syngas.

The Impact of Heating Rate

A fast heating rate is non-negotiable for fast pyrolysis. This is the only way to ensure the biomass particles break down via the desired chemical pathways before competing reactions can take over.

Feedstock Characteristics

The type, moisture content, and particle size of the biomass all influence the ideal residence time and temperature. What works for wood chips may need adjustment for agricultural straws.

Understanding the Trade-offs

While fast pyrolysis excels at producing high yields of liquid, it is not without its challenges and compromises.

High Liquid Yield vs. Liquid Quality

The speed of the process yields a crude, complex liquid. Bio-oil is acidic, contains significant water, and is chemically unstable, making it corrosive and difficult to store.

It cannot be used as a drop-in transportation fuel without significant and costly upgrading. The speed gets you a high quantity of a low-quality precursor.

Engineering Complexity

Achieving extremely high heating rates and precise, short residence times requires sophisticated and expensive reactors, such as circulating fluidized beds or ablative pyrolyzers.

This engineering challenge is a major factor in the capital cost and scalability of fast pyrolysis plants.

The Feedstock Preparation Challenge

To facilitate rapid heating, the biomass feedstock must be thoroughly dried and finely ground. This pre-processing step consumes significant energy and adds operational cost and complexity to the overall system.

Making the Right Choice for Your Goal

The term "pyrolysis" covers a range of processes, each optimized for a different outcome. Choosing the right one depends entirely on your end goal.

- If your primary focus is maximizing liquid fuel precursors: Fast pyrolysis is the definitive choice due to its rapid heating and quenching that favors bio-oil production.

- If your primary focus is creating stable, solid biochar for soil amendment: Slow pyrolysis, with its much longer residence times (hours to days) and lower temperatures, is the superior process.

- If your primary focus is producing syngas for power generation or chemical synthesis: Gasification, which involves even higher temperatures and the use of a controlled oxidant, is the correct pathway.

Ultimately, understanding the relationship between time, temperature, and product yield is the key to harnessing biomass conversion for any specific application.

Summary Table:

| Key Characteristic | Typical Value | Importance |

|---|---|---|

| Vapor Residence Time | 0.5 - 2 seconds | Maximizes bio-oil yield by preventing vapor breakdown |

| Optimal Temperature | 450°C - 550°C | The 'sweet spot' for maximizing liquid production |

| Primary Product | Bio-oil (up to 75% yield) | A liquid fuel precursor requiring further upgrading |

| Ideal Feedstock | Finely ground, dry biomass | Enables the rapid, uniform heating required for the process |

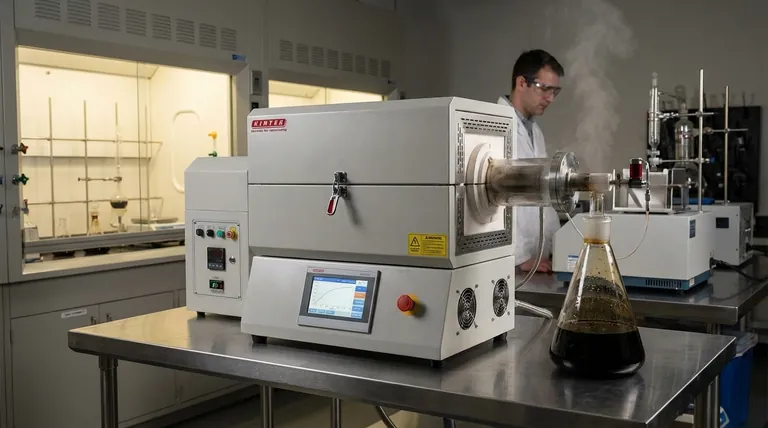

Ready to Optimize Your Biomass Conversion Process?

Understanding the precise timing and conditions of fast pyrolysis is crucial for maximizing your bio-oil yield. The right laboratory equipment is essential for research, development, and quality control in this field.

KINTEK specializes in lab equipment and consumables, serving laboratory needs. We provide the reliable tools you need to accurately simulate and analyze fast pyrolysis processes, from reactor systems to analytical instruments.

Let us help you enhance your biomass conversion efficiency and achieve your research goals.

Contact our experts today to discuss your specific application and find the perfect solution for your lab.

Visual Guide

Related Products

- Rotary Tube Furnace Split Multi Heating Zone Rotating Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How are tube furnaces classified based on the orientation of the tube? Choose the Right Design for Your Process

- At what temperature does wood pyrolysis begin? Control the Process for Biochar, Bio-Oil, or Syngas

- How do tube furnaces or muffle furnaces ensure stoichiometric accuracy during synthesis? Mastering Li4GeO4 & Li4VO4

- Why is a high-temperature furnace with multi-probe testing used for ABO3 perovskite? Get Precise Conductivity Data

- How are composites processed using sintering? Engineered Material Solutions Through Advanced Thermal Bonding