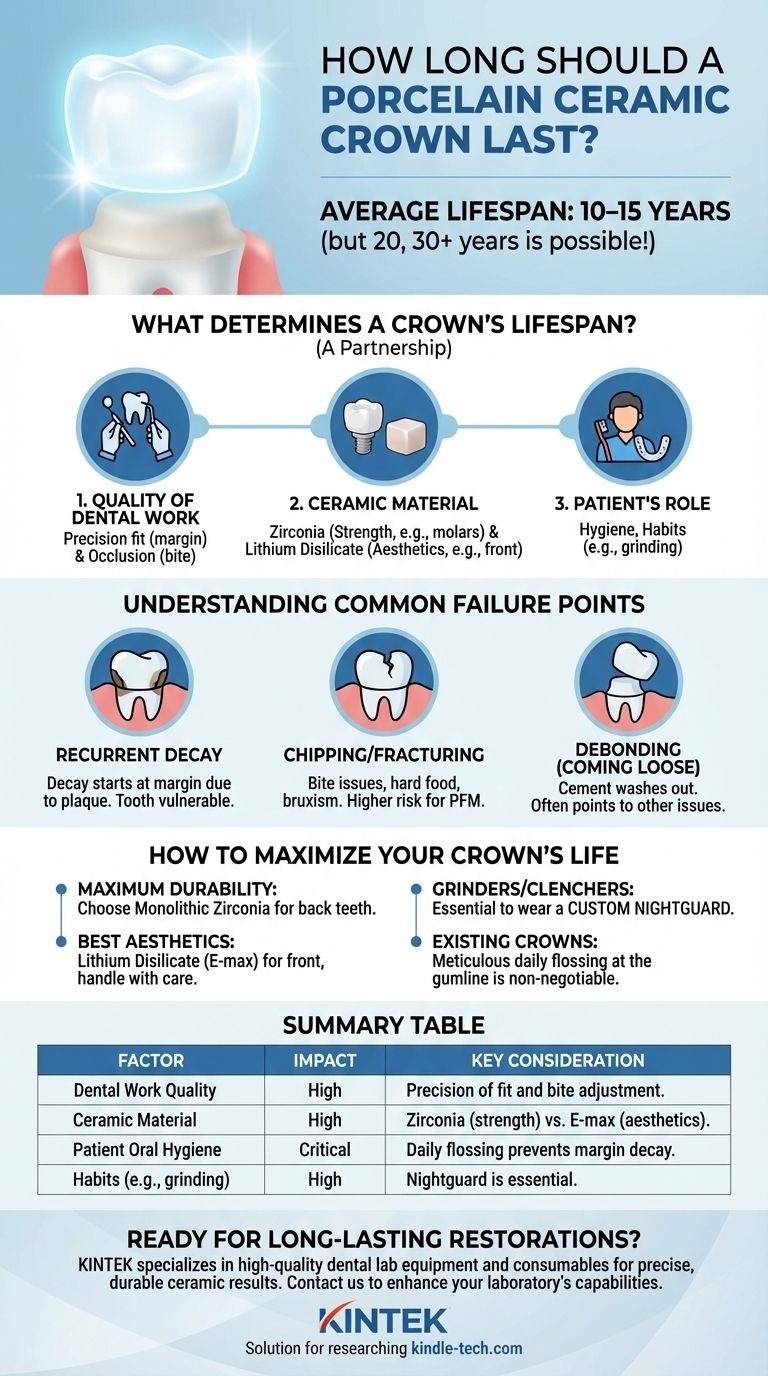

On average, a well-made and properly maintained porcelain ceramic crown should last between 10 and 15 years. However, this is just an average, and it's not uncommon for crowns to last 20, 30, or even more years. The lifespan is less about the material itself and more about the factors surrounding its placement and your long-term care.

The longevity of a dental crown is not a fixed guarantee. It is a direct outcome of the quality of the initial dental work, the specific material chosen for the job, and most importantly, your daily oral hygiene and personal habits.

What Determines a Crown's Lifespan?

A crown is not a standalone object; it's part of a complex biological system. Its success depends on the harmony between the material, the dentist's work, and the patient's role.

The Quality of the Dental Work

The skill of the dentist is arguably the most critical factor at the outset. A perfectly executed procedure creates a foundation for longevity.

Key elements include the precision of the fit at the gumline (the "margin") and the occlusion, which is how the crown contacts the opposing teeth when you bite. A poorly sealed margin allows bacteria to seep underneath, leading to decay of the natural tooth. Improper occlusion can create focused stress points, leading to chipping or fracture.

The Specific Ceramic Material

Not all "porcelain" is the same. Modern dentistry uses several types of advanced ceramics, each with different properties.

- Zirconia: This is a type of ceramic known for its exceptional strength and fracture resistance. Monolithic zirconia (made from a single block) is extremely durable and is a common choice for molars that endure heavy chewing forces.

- Lithium Disilicate (e.g., E-max): This material offers superior aesthetics and translucency, making it an excellent choice for front teeth. While very strong, it is generally not as fracture-resistant as zirconia.

The choice of material is a strategic decision made by you and your dentist based on the tooth's location and your functional needs.

The Patient's Role: Your Habits and Hygiene

This is the factor you have the most control over. A crown covers the tooth, but the underlying tooth structure and the gumline are still vulnerable.

Excellent oral hygiene is non-negotiable. This means brushing twice a day and, crucially, flossing or using an interdental cleaner daily to keep the crown's margins free of plaque.

Parafunctional habits like bruxism (grinding or clenching your teeth), chewing ice, or using your teeth to open packages can place extreme stress on a crown and dramatically shorten its life.

Understanding Common Failure Points

Trust is built on understanding the potential downsides. Knowing why crowns fail is key to preventing those failures.

Recurrent Decay

A crown itself cannot decay, but the natural tooth underneath it can. This is the most common reason for crown failure.

Decay almost always starts at the crown margin—the seam where the crown meets the tooth. If plaque is allowed to accumulate here, it will cause a cavity that undermines the crown's foundation.

Chipping or Fracturing

While modern ceramics are very strong, they are not indestructible. A porcelain crown can chip, especially if the bite is not perfectly adjusted or if you bite down on something unexpectedly hard.

This risk is higher for porcelain-fused-to-metal (PFM) crowns, where a layer of porcelain can chip off the underlying metal, or for crowns on patients who grind their teeth without a nightguard.

Debonding (Coming Loose)

A crown is held in place with specialized dental cement. Over time, this cement can wash out, or the bond can fail, causing the crown to become loose or fall off.

This is often a sign of an underlying issue, such as a poor initial fit or decay that has compromised the tooth structure holding the crown.

How to Maximize the Life of Your Crown

Your actions and decisions directly influence the return on your investment.

- If your primary focus is maximum durability (e.g., for a back molar): Discuss monolithic zirconia with your dentist, as its strength is ideal for withstanding heavy chewing forces.

- If your primary focus is aesthetics (e.g., for a front tooth): A material like lithium disilicate (E-max) is often the best choice, but you must be committed to protecting it from excessive force.

- If you grind or clench your teeth: Invest in a custom-fit nightguard from your dentist and wear it diligently. This is the single best way to protect all your teeth, including your crowns, from destructive forces.

- If you already have a crown: Treat the gumline around it as a top priority. Floss meticulously every day and have it examined during your regular dental check-ups.

Ultimately, a dental crown is a long-term partnership between you and your dental team, and your daily habits are the key to its enduring success.

Summary Table:

| Factor | Impact on Lifespan | Key Consideration |

|---|---|---|

| Dental Work Quality | High | Precision of fit and bite adjustment are critical. |

| Ceramic Material | High | Zirconia for strength; E-max for aesthetics. |

| Patient Oral Hygiene | Critical | Daily flossing prevents decay at the crown margin. |

| Habits (e.g., grinding) | High | A nightguard is essential for teeth grinders. |

Ready to ensure your lab work supports long-lasting dental restorations? The quality of the materials and equipment used in creating dental ceramics is foundational to their success. KINTEK specializes in providing high-quality lab equipment and consumables for dental laboratories, ensuring precise and reliable results. Whether you're working with zirconia or lithium disilicate, having the right tools is the first step toward creating durable crowns. Contact us today via our [#ContactForm] to discuss how our solutions can enhance your laboratory's capabilities and contribute to producing restorations that stand the test of time.

Visual Guide

Related Products

- Graphite Vacuum Furnace Negative Material Graphitization Furnace

- Horizontal High Temperature Graphite Vacuum Graphitization Furnace

- 1200℃ Muffle Furnace Oven for Laboratory

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1200℃ Split Tube Furnace with Quartz Tube Laboratory Tubular Furnace

People Also Ask

- What are the different types of dental furnaces? Choose the Right Furnace for Your Dental Lab

- How long does ceramic teeth last? Maximize Your Smile's Lifevity with Expert Care

- What type of zirconia is most commonly used in dentistry? Choose Between Strength and Aesthetics

- Are ceramic crowns stain-resistant? Discover the Secret to a Lasting, Bright Smile

- How do you fix a broken ceramic tooth? Get Professional Repair & Restoration Solutions

- What is dental ceramic used for? Restore Teeth with Aesthetic, Durable Crowns & Fillings

- What are some common features of modern Dental Press Furnaces? Boost Lab Efficiency with Smart Technology

- What is the firing temperature of dental porcelain? A Guide to Classes from Ultra-Low to High-Fusing