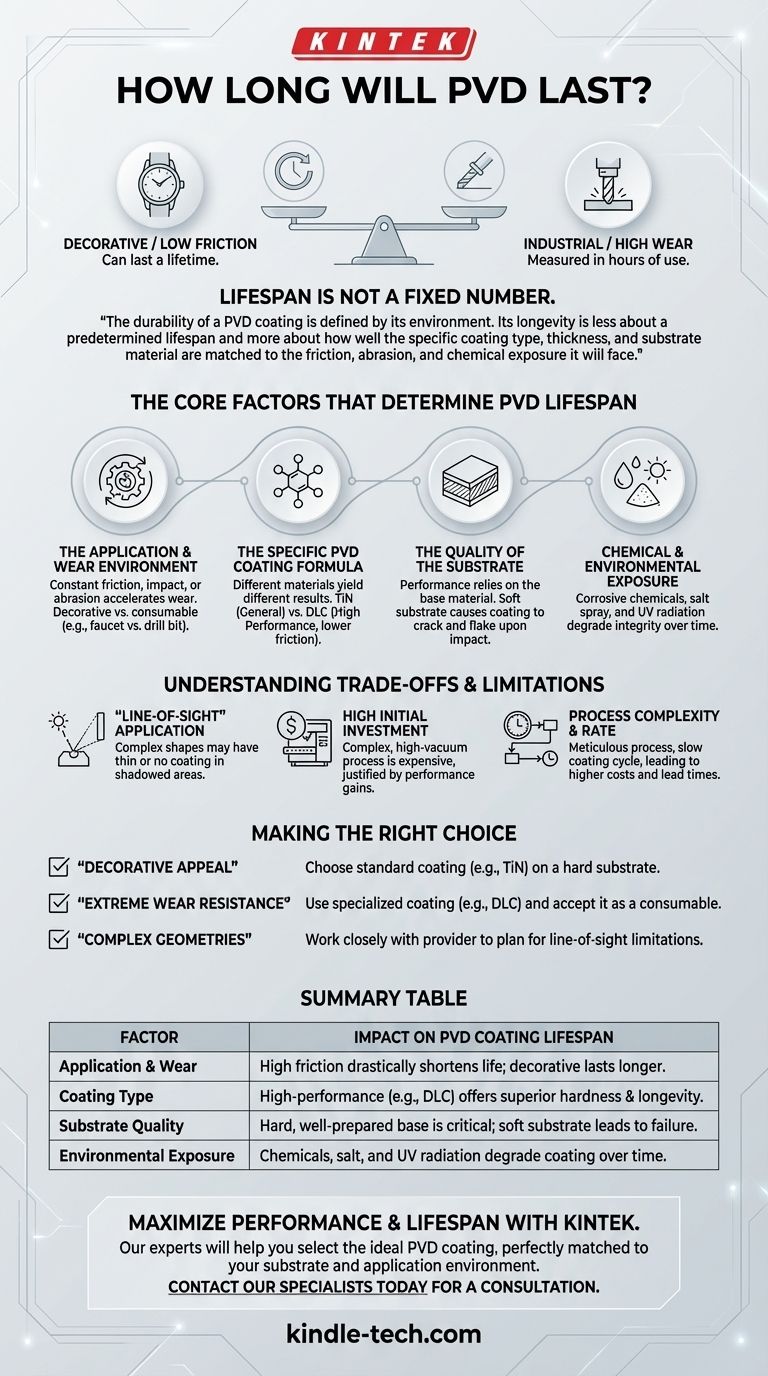

The lifespan of a PVD coating is not a fixed number; it is entirely dependent on its application. For a decorative item like a watch case that sees minimal friction, a PVD finish can last a lifetime. However, on a high-wear industrial cutting tool, that same coating might be measured in hours of operational use before it needs replacement.

The durability of a Physical Vapor Deposition (PVD) coating is defined by its environment. Its longevity is less about a predetermined lifespan and more about how well the specific coating type, thickness, and substrate material are matched to the friction, abrasion, and chemical exposure it will face.

The Core Factors That Determine PVD Lifespan

To accurately estimate the longevity of a PVD coating, you must move beyond the general term and analyze the specific variables of your application.

The Application and Wear Environment

This is the single most important factor. An item that experiences constant friction, impact, or abrasion will wear down the coating much faster than a static or decorative part.

A PVD-coated faucet may look pristine for decades, while a PVD-coated drill bit is a consumable, designed to wear away over a specific period of intense use.

The Specific PVD Coating Formula

"PVD" is a category, not a single coating. Different materials are deposited to achieve different outcomes, each with its own durability profile.

Titanium Nitride (TiN) is a common, general-purpose hard coating. In contrast, coatings like Diamond-Like Carbon (DLC) offer superior hardness and lower friction, providing a much longer service life in high-wear mechanical applications.

The Quality of the Substrate

PVD coatings are extremely thin, often only a few microns. They are not structural. Their performance is critically dependent on the hardness and preparation of the material underneath.

If the base metal is soft, a significant impact can cause it to dent. The hard PVD coating, unable to flex, will crack and flake off, even if the coating itself was not breached.

Chemical and Environmental Exposure

The environment plays a crucial role. Constant exposure to corrosive chemicals, salt spray, or even high levels of UV radiation can degrade the coating's integrity over time, leading to premature failure.

Understanding the Trade-offs and Limitations

While PVD offers exceptional surface properties, it's essential to recognize its inherent constraints, which directly impact its feasibility and cost-effectiveness.

The "Line-of-Sight" Application

The PVD process deposits material in a straight line from the source to the target. This means that complex shapes can suffer from a "shadowing" effect.

Areas on the back or in deep crevices of a part may receive a much thinner coating or no coating at all, creating weak points that will wear out quickly.

High Initial Investment

The equipment required for PVD is complex and operates under a high vacuum, making it an expensive process.

This cost is often justified by the performance gains, but it must be factored into the overall value analysis, especially when comparing it to other surface treatments.

Process Complexity and Rate

Loading parts into a PVD reactor is a meticulous process, and the coating cycle itself can be slow. This low rate of yield contributes to the high cost and longer lead times.

These factors make PVD less suitable for low-cost, high-volume parts where durability is not the absolute highest priority.

Making the Right Choice for Your Goal

To maximize the lifespan of a PVD coating, you must select the right process for your specific need.

- If your primary focus is decorative appeal with scratch resistance: A standard coating like TiN on a hard substrate is an excellent choice that will likely last the lifetime of the product.

- If your primary focus is extreme wear resistance for industrial tools: You must use a specialized, high-performance coating like DLC or TiAlN and accept that it is a consumable surface that will eventually require recoating.

- If you are coating parts with complex geometries: You must work closely with your coating provider to plan for PVD's line-of-sight limitations, which may require special fixtures or part rotation during the process.

Ultimately, viewing PVD not as a permanent shield but as a high-performance surface engineered for a specific task is the key to its successful application.

Summary Table:

| Factor | Impact on PVD Coating Lifespan |

|---|---|

| Application & Wear | High friction/abrasion drastically shortens life; decorative items can last a lifetime. |

| Coating Type (e.g., TiN vs. DLC) | High-performance coatings like DLC offer superior hardness and longevity. |

| Substrate Quality | A hard, well-prepared base is critical; a soft substrate leads to coating failure. |

| Environmental Exposure | Chemicals, salt, and UV radiation can degrade the coating over time. |

Maximize the performance and lifespan of your components with the right PVD coating solution.

At KINTEK, we specialize in precision lab equipment and consumables, including advanced coating services. Our experts will help you select the ideal PVD coating—whether for durable industrial tools or long-lasting decorative finishes—ensuring it is perfectly matched to your substrate and application environment.

Don't leave your coating's durability to chance. Contact our specialists today for a consultation and let KINTEK enhance your product's longevity and performance.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What is meant by vapor deposition? A Guide to Atomic-Level Coating Technology

- What is PECVD used for? Achieve Low-Temperature, High-Performance Thin Films

- What is the difference between CVD and PECVD? Choose the Right Thin-Film Deposition Method

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition