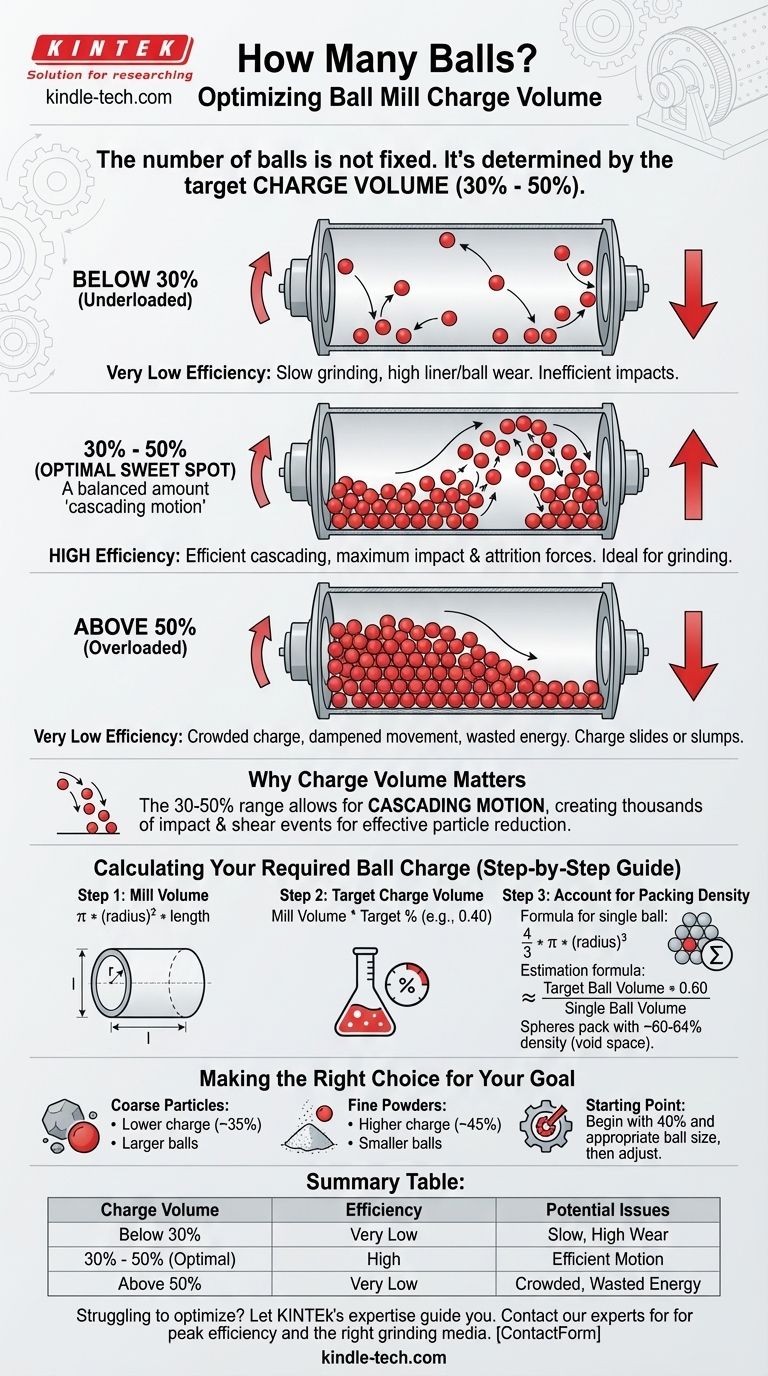

The number of balls needed for a ball mill is not a fixed count, but rather is determined by the target charge volume—the percentage of the mill's internal volume filled by the grinding media. For most applications, this volume should be between 30% and 50%. Focusing on this percentage, rather than a specific number of balls, is the key to achieving efficient and effective grinding.

The optimal grinding performance in a ball mill hinges on achieving the correct charge volume. This ensures the grinding media has enough space to move effectively, maximizing the impact and attrition forces that break down the material.

Why Charge Volume is the Critical Metric

A common mistake is to ask "how many" balls are needed without first defining the total volume they must occupy. The charge volume dictates the entire mechanical action inside the mill.

The "Sweet Spot": 30% to 50%

The 30-50% range is considered the industry-standard "sweet spot" for efficient operation.

- Below 30%, there are too few ball-on-ball and ball-on-particle impacts, leading to very slow and inefficient grinding. It also increases wear on the mill's liner as balls directly strike the cylinder wall.

- Above 50%, the ball charge becomes too crowded. This severely restricts the movement of the balls, muffling their impact and reducing the cascading action necessary for grinding. The charge begins to slide or slump rather than tumble, wasting energy.

How Movement Creates Grinding Action

The effectiveness of a ball mill depends entirely on the motion of the balls inside. This motion is primarily controlled by the mill's rotational speed and its charge volume.

The goal is to create a cascading motion, where balls are lifted up the side of the rotating mill and then tumble down over the rest of the charge. This continuous action creates the thousands of impact and shear (attrition) events that reduce particle size.

Calculating Your Required Ball Charge

While the exact number of balls is a secondary concern, you can estimate it once you determine the ideal charge volume and ball size for your application.

Step 1: Calculate the Mill's Internal Volume

First, you need the volume of the grinding chamber. For a standard cylindrical mill, the formula is:

Mill Volume = π * (radius)² * length

Ensure you use consistent units (e.g., cubic centimeters or cubic inches).

Step 2: Determine Your Target Charge Volume

Decide on your target percentage based on your grinding needs (e.g., 40%).

Target Ball Volume = Mill Volume * 0.40

This gives you the total volume that your grinding balls must fill.

Step 3: Account for Ball Size and Packing Density

Now, calculate the volume of a single grinding ball:

Single Ball Volume = 4/3 * π * (radius)³

Crucially, spheres do not pack perfectly; there will always be void space between them. The packing density for randomly packed uniform spheres is approximately 60-64%.

To get a practical estimate of the number of balls needed, use this formula:

Number of Balls ≈ (Target Ball Volume * 0.60) / Single Ball Volume

This calculation provides a strong starting point, which can then be fine-tuned based on observed performance.

Understanding the Trade-offs

Optimizing a ball mill is a process of balancing competing factors. Choosing the wrong charge volume can severely hinder your results.

The Pitfall of Overloading (>50%)

An overloaded mill is highly inefficient. The grinding media is too constrained to be lifted and cascade properly. This dampened movement drastically reduces impact energy, significantly slows down the grinding process, and consumes excess power for minimal return.

The Problem with Underloading (<30%)

An underloaded mill is not only inefficient but can also be damaging. With too few balls, the energy from the mill's rotation is transferred into high-velocity impacts between the balls and the mill liner itself, causing accelerated and costly wear on both the media and the equipment.

Making the Right Choice for Your Goal

The optimal setup depends on the material you are processing and your desired final particle size. Use these principles as a starting guide.

- If your primary focus is breaking down large, coarse particles: Start with a lower-end charge volume (~35%) using larger, heavier balls to maximize the impact energy of each collision.

- If your primary focus is producing very fine powders: Use a higher-end charge volume (~45%) with smaller grinding balls to increase the total surface area and the number of attrition points within the mill.

- If you are starting a new process without a baseline: Begin with a 40% charge volume and a ball size appropriate for your feed material, then adjust based on the efficiency and quality of your results.

Ultimately, understanding the principles of charge volume empowers you to move beyond simple formulas and intelligently optimize your milling process.

Summary Table:

| Charge Volume | Grinding Efficiency | Potential Issues |

|---|---|---|

| Below 30% | Very Low | Slow grinding, high liner/ball wear |

| 30% - 50% (Optimal) | High | Efficient cascading motion, maximum impact |

| Above 50% | Very Low | Crowded charge, dampened movement, wasted energy |

Struggling to optimize your milling process? Let KINTEK's expertise guide you to peak efficiency. We specialize in lab equipment and consumables, providing the right grinding media and technical support to ensure your ball mill operates within the ideal charge volume for superior results. Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Laboratory Jar Ball Mill with Alumina Zirconia Grinding Jar and Balls

- High-Energy Omnidirectional Planetary Ball Mill Milling Machine for Laboratory

- High-Energy Omnidirectional Planetary Ball Mill Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

- High Energy Planetary Ball Mill Milling Machine for Laboratory

People Also Ask

- What is the function of a planetary ball mill in MAX phase powder preparation? Unlock High-Purity Atomic Homogeneity

- What is the primary function of a planetary ball mill in ODS steel prep? Achieving Nanoscale Mechanical Alloying

- How does a planetary ball mill facilitate the Mechanochemical Synthesis of sulfide solid electrolytes? - Anneal-Free

- What is the primary function of a planetary ball mill? Mastering SiC/Al Composite Mixing for Homogeneity

- What is the speed range of a ball mill? Find Your Optimal Grinding Efficiency