At its core, microwave plasma is generated by using high-frequency electromagnetic waves to energize a gas within a controlled environment. These waves, typically at a frequency of 2.45 GHz, are highly efficient at transferring energy to free electrons. This energy transfer initiates a collisional cascade that strips electrons from neutral atoms, transforming the gas into a reactive, ionized state known as plasma.

The fundamental process is not about heating the gas directly, but about selectively energizing electrons. These super-energized electrons then act as catalysts, colliding with and ionizing the surrounding gas atoms in a self-sustaining chain reaction.

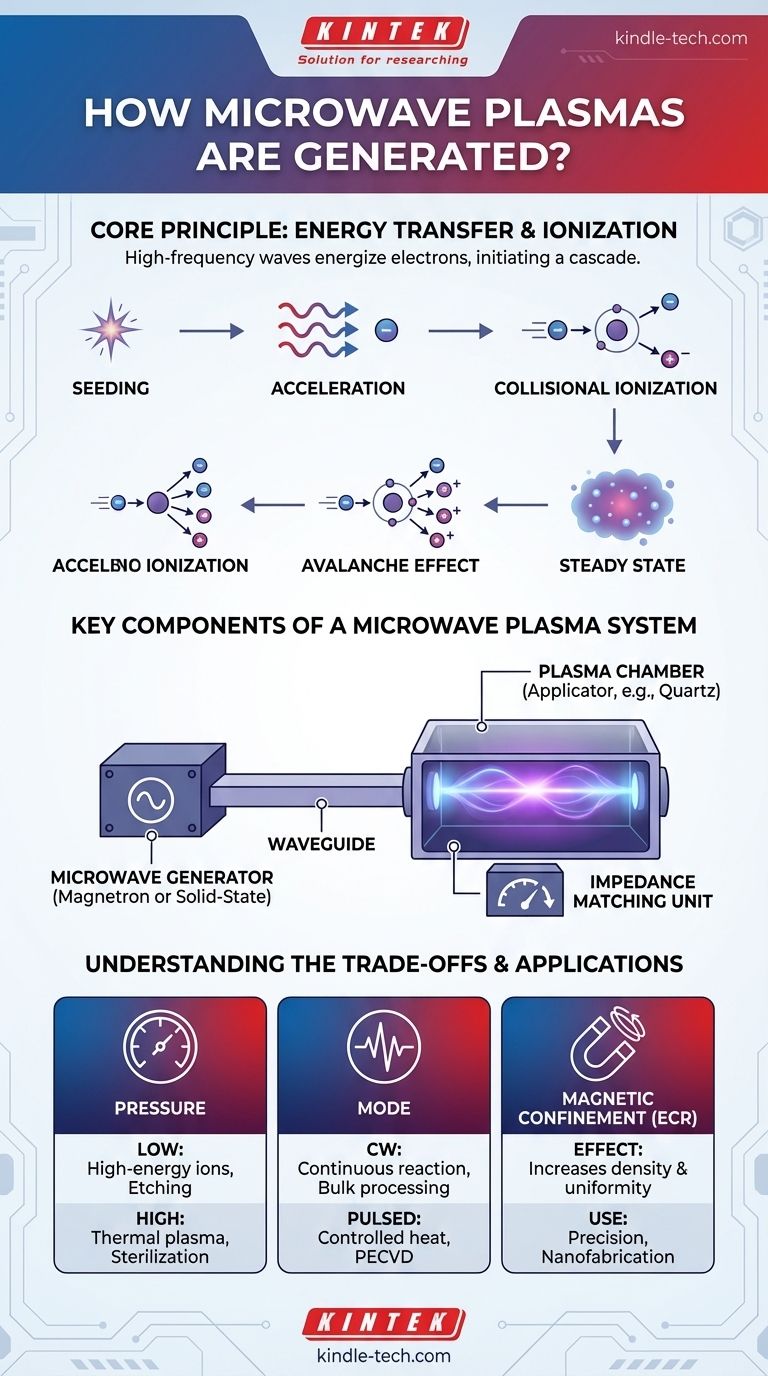

The Core Principle: Energy Transfer and Ionization

The creation of microwave plasma is a multi-stage process rooted in fundamental physics. It relies on the efficient absorption of microwave energy and the subsequent ionization of a gas.

The Role of Microwaves

Microwaves, a form of electromagnetic radiation, are uniquely suited for this task. Their oscillating electric field effectively "grabs" and accelerates free-roaming electrons within the gas.

The standard industrial frequency of 2.45 GHz provides a rapid, oscillating field that reverses direction billions of times per second, ensuring continuous energy input to the electrons.

The Ignition Phase: Seeding Free Electrons

A plasma cannot form from a perfectly neutral gas. The process must begin with a few initial "seed" electrons.

These seed electrons are always present due to natural background radiation or can be intentionally created using a brief, high-voltage pulse to kickstart the process.

The Avalanche Effect: A Chain Reaction

Once an initial electron is accelerated by the microwave field, it gains significant kinetic energy. When this high-energy electron collides with a neutral gas atom, it can knock another electron loose.

This collisional ionization is the critical step. Now, there are two free electrons where there was one. The microwave field accelerates both, which then create more collisions, leading to four electrons, then eight, and so on. This exponential growth is known as the avalanche effect.

Reaching a Steady State

This avalanche does not continue indefinitely. The plasma stabilizes when the rate of ionization is balanced by the rate of recombination, where electrons and ions meet and re-form neutral atoms. This equilibrium determines the plasma's final density and temperature.

Key Components of a Microwave Plasma System

Generating a stable, useful plasma requires a precisely engineered system. While designs vary, they share several core components.

The Microwave Generator

This is the power source. Historically, this has been a magnetron—a cost-effective and robust vacuum tube also found in a household microwave oven.

Modern systems increasingly use solid-state generators. While more expensive, they offer far superior control over power, frequency, and pulsing, which is critical for advanced applications.

The Waveguide

The waveguide is essentially a "pipe" for microwaves. It is a hollow, metallic conductor that channels the high-frequency energy from the generator to the plasma chamber with minimal loss.

The Plasma Chamber (or Applicator)

This is the vessel where the plasma is formed. It is typically a vacuum chamber made of quartz, ceramic, or metal, designed to contain the process gas at a specific pressure. Its geometry is engineered to concentrate the microwave energy effectively.

The Impedance Matching Unit

This is a crucial tuning component. The plasma's properties change as it ignites, creating a variable "load" on the generator. The matching unit ensures maximum power is transferred to the plasma and not reflected back to the generator, which could cause damage. It is analogous to tuning a radio to a specific station for the clearest signal.

Understanding the Trade-offs

The characteristics of the resulting plasma are not fixed; they are highly dependent on the operating parameters. Understanding these trade-offs is key to tailoring the plasma for a specific task.

Pressure's Critical Role

The pressure of the gas inside the chamber is a dominant factor. At low pressures, electrons travel farther before colliding, allowing them to accumulate very high energy. This is ideal for surface modification where you want high-energy ion bombardment but minimal heating of the substrate.

At high or atmospheric pressures, frequent collisions prevent electrons from gaining extreme energy. Instead, the energy is distributed among all particles, leading to a "thermal" plasma where the gas itself becomes very hot. This is useful for bulk material processing or sterilization.

Continuous Wave (CW) vs. Pulsed Mode

Plasma can be generated with a continuous wave of microwave power (CW) or in short bursts (pulsed mode). Pulsed operation is a powerful tool for controlling the process.

By turning the power on and off rapidly, you can manage the total heat delivered to a sensitive material while still benefiting from the chemical reactivity of the plasma during the "on" cycle.

The ECR Advantage: Magnetic Confinement

For high-performance applications like semiconductor etching, a magnetic field can be added. In Electron Cyclotron Resonance (ECR) plasma sources, a magnetic field forces electrons into a spiral path.

This drastically increases the path length of the electrons, raising the probability of an ionizing collision even at very low pressures. ECR systems generate exceptionally high-density, uniform plasmas with low ion energy, offering unparalleled precision.

How to Apply This to Your Project

The right plasma generation method depends entirely on your technical goal.

- If your primary focus is precision etching or nanofabrication: You need a high-density, low-pressure plasma for maximum control, making an ECR or solid-state pulsed system the superior choice.

- If your primary focus is rapid sterilization or bulk surface treatment: A simpler, high-power CW magnetron system operating at or near atmospheric pressure is likely the most cost-effective solution.

- If your primary focus is thin-film deposition (PECVD): You need to balance chemical reactivity with substrate temperature, making a low-to-medium pressure pulsed system an ideal tool for fine-tuning film quality.

Ultimately, understanding how microwaves create plasma empowers you to select and control a uniquely versatile and powerful industrial tool.

Summary Table:

| Key Component | Primary Function | Common Types |

|---|---|---|

| Microwave Generator | Produces high-frequency energy | Magnetron, Solid-State |

| Waveguide | Channels microwaves to plasma chamber | Hollow metallic conductor |

| Plasma Chamber | Contains gas and plasma reaction | Quartz, Ceramic, Metal |

| Impedance Matching Unit | Maximizes power transfer, prevents reflection | Tunable network |

| Operating Parameter | Effect on Plasma | Typical Use Cases |

| Pressure (Low vs. High) | Low: High-energy ions; High: Thermal plasma | Etching (low), Sterilization (high) |

| Mode (CW vs. Pulsed) | CW: Continuous reaction; Pulsed: Controlled heat | PECVD (pulsed), Bulk processing (CW) |

| Magnetic Confinement (ECR) | Increases plasma density and uniformity | Semiconductor etching, Precision applications |

Ready to harness the power of microwave plasma in your lab? KINTEK specializes in high-performance lab equipment, including plasma systems tailored for etching, sterilization, PECVD, and more. Our experts can help you select the right configuration—whether you need a cost-effective magnetron system or a precision solid-state ECR source. Contact us today to discuss your project and discover how KINTEK’s solutions can enhance your research and processing capabilities!

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

People Also Ask

- How does PECVD work? Enable Low-Temperature, High-Quality Thin Film Deposition

- What is the process of vacuum vapor deposition? Mastering CVD and PVD Thin-Film Coating

- What are the different types of thin films? A Guide to Optical, Electrical, and Functional Coatings

- What is the vapor phase deposition technique? A Guide to PVD & CVD Thin-Film Coating Methods

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application