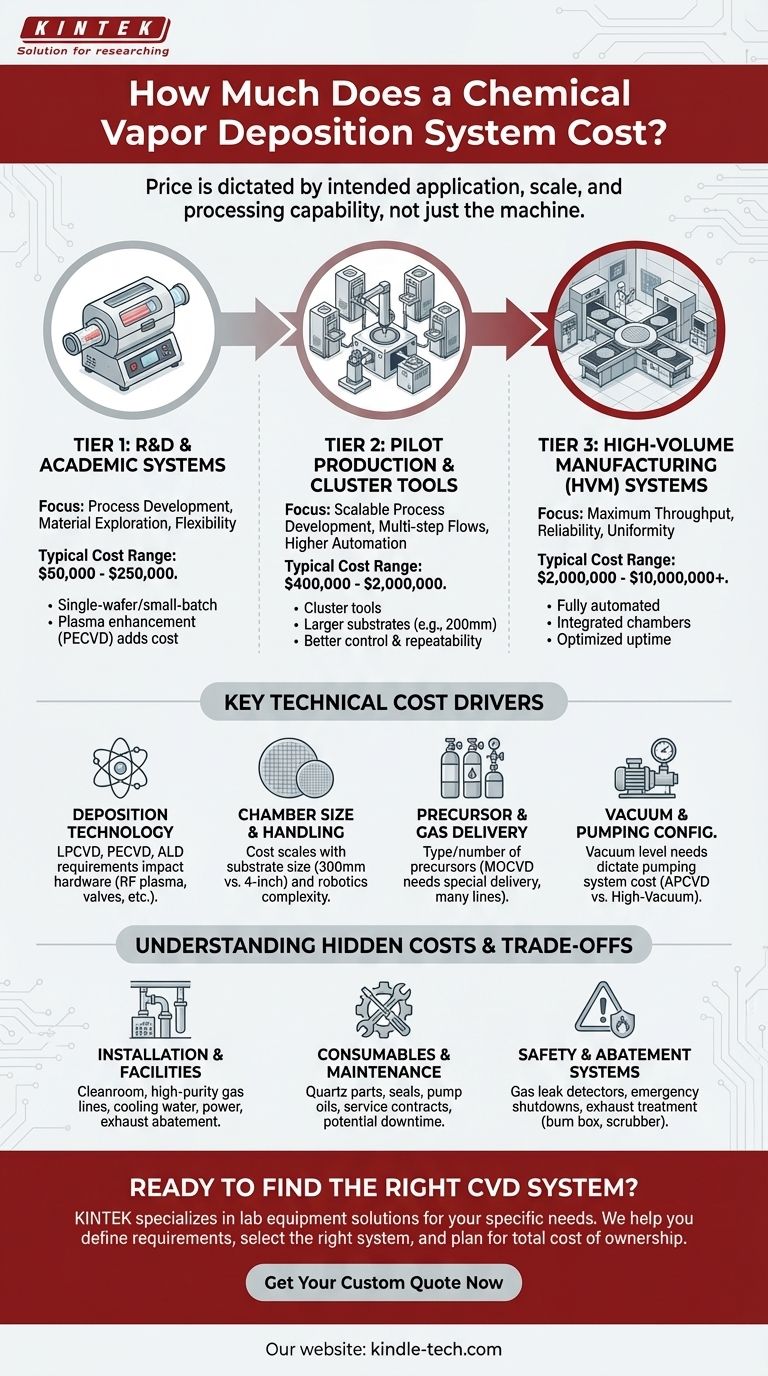

To state a single price for a Chemical Vapor Deposition (CVD) system is impossible, as the cost is dictated entirely by its intended application and scale. A small, manually operated tube furnace for academic research can cost between $50,000 and $250,000. In contrast, a fully automated, high-volume production system for manufacturing semiconductors can easily exceed $5 million.

The central takeaway is this: you are not buying a "machine," you are buying a specific processing capability. The final cost of a CVD system is a direct function of the material you need to deposit, the size and volume of substrates you need to process, and the level of precision and automation your application demands.

The Spectrum of CVD Systems: From Lab to Fab

The most significant factor driving the cost of a CVD system is its scale and intended use, which can be broadly categorized into three tiers.

R&D and Academic Systems

These are typically the most affordable systems, designed for flexibility and material exploration rather than throughput. They are often single-wafer or small-batch tube furnaces.

The focus here is on process development. Researchers need the ability to easily change parameters, precursors, and configurations. Costs typically range from $50,000 to $250,000, with complexity and features like plasma enhancement (PECVD) pushing the price toward the higher end of that spectrum.

Pilot Production and Cluster Tools

These systems bridge the gap between pure research and full-scale manufacturing. They often take the form of "cluster tools," where a central robotic handler moves wafers between multiple process chambers and load locks.

This setup allows for developing multi-step process flows without breaking vacuum, which is critical for creating advanced devices. These systems feature higher levels of automation, handle larger substrates (e.g., 200 mm wafers), and offer much better process control and repeatability. Expect costs to be in the $400,000 to $2 million range.

High-Volume Manufacturing (HVM) Systems

At the highest end are the large, fully automated systems found in semiconductor fabs. These tools are designed for maximum throughput, reliability, and uniformity across large substrates (e.g., 300 mm wafers).

Every component is optimized for uptime and minimizing the cost-per-wafer. These systems are incredibly complex, often involving multiple integrated deposition chambers and sophisticated software that ties into the factory's manufacturing execution system (MES). The price for these HVM systems starts around $2 million and can exceed $10 million.

Key Technical Factors That Drive System Cost

Beyond the general scale, several specific technical choices have a major impact on the final price tag. Understanding these will help you define your requirements.

Deposition Technology (PECVD vs. LPCVD vs. ALD)

The underlying physics of the deposition method dictates the hardware.

- LPCVD (Low-Pressure CVD) requires a robust high-vacuum system, including expensive turbomolecular pumps, to achieve low pressure.

- PECVD (Plasma-Enhanced CVD) adds the complexity and cost of an RF plasma generator, an impedance matching network, and a showerhead electrode design.

- ALD (Atomic Layer Deposition) demands extremely precise, fast-acting precursor delivery valves and sophisticated software for timing the micro-dosing cycles.

Chamber Size and Substrate Handling

The cost scales exponentially with substrate size. A chamber designed for uniform deposition over a 300mm wafer is vastly more complex and expensive to engineer than one for a 4-inch wafer. The cost also includes the robotics for automated wafer handling, which becomes more sophisticated for larger, heavier substrates.

Precursor and Gas Delivery System

The type and number of chemical precursors directly influence cost. A simple system using standard gases like silane and ammonia requires a few mass flow controllers (MFCs). A complex system for MOCVD (Metalorganic CVD) may need heated lines, special liquid or solid precursor delivery units, and many more gas lines, all of which add significant cost and complexity.

Vacuum and Pumping Configuration

The required vacuum level is a primary cost driver. Atmospheric pressure systems (APCVD) may only need simple exhaust. In contrast, high-vacuum systems require multi-stage pumping configurations, pressure controllers, and vacuum gauges, which can cost tens of thousands of dollars on their own.

Understanding the Hidden Costs and Trade-offs

The initial purchase price is only one part of the total cost of ownership. Failing to budget for these associated expenses is a common and costly mistake.

Installation and Facilities

A CVD system does not operate in a vacuum (no pun intended). It requires significant facility infrastructure, including a cleanroom environment, high-purity process gas lines, cooling water, specialized electrical power, and, critically, an exhaust and abatement system. These facility costs can sometimes equal or exceed the cost of the tool itself.

Consumables and Maintenance

CVD systems have numerous consumable parts. Quartz tubes and boats, o-rings, seals, pump oils, and filters need regular replacement. A lower-cost system may use cheaper components that wear out faster, leading to higher long-term operating costs and more downtime. Always factor in the price of a service contract, especially for complex production tools.

Safety and Abatement Systems

Many CVD precursors are highly toxic, flammable, or pyrophoric (ignite spontaneously in air). A proper safety system is non-negotiable. This includes gas leak detectors, emergency shutdowns, and an abatement system (like a burn box or wet scrubber) to treat the toxic exhaust stream before it is vented. Skimping on safety is a recipe for disaster.

Defining Your Needs to Get an Accurate Quote

To move from a vague price range to a firm quote, you must first provide vendors with a clear definition of your process requirements.

- If your primary focus is fundamental research or education: Your priority should be a flexible, modular tube furnace system that allows for a wide range of materials and process conditions.

- If your primary focus is developing a scalable commercial process: You should invest in a pilot-scale cluster tool with excellent automation and data logging to ensure your results are repeatable.

- If your primary focus is high-volume manufacturing: Your decision should be driven by throughput, reliability, and cost-per-substrate from an established vendor with a proven support record.

Ultimately, the cost of a CVD system is a direct reflection of the problem you are trying to solve.

Summary Table:

| System Type | Primary Use Case | Typical Cost Range |

|---|---|---|

| R&D / Academic | Material exploration, process development | $50,000 - $250,000 |

| Pilot Production | Scalable process development, multi-step flows | $400,000 - $2,000,000 |

| High-Volume Manufacturing (HVM) | Maximum throughput & reliability for fabs | $2,000,000 - $10,000,000+ |

Ready to find the right CVD system for your budget and application?

Navigating the wide range of CVD system costs and specifications can be complex. KINTEK specializes in providing lab equipment solutions tailored to your specific needs, whether you are in academic research, pilot production, or high-volume manufacturing.

We can help you:

- Define your technical requirements to get an accurate quote.

- Select the right system (PECVD, LPCVD, ALD) for your material and process goals.

- Plan for total cost of ownership, including installation, consumables, and maintenance.

Contact us today for a personalized consultation and let our experts guide you to the optimal CVD solution. Get Your Custom Quote Now

Visual Guide

Related Products

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- What are the methods of deposition? A Guide to PVD and CVD Thin-Film Techniques

- What are the steps of the CVD process? A Guide to Precision Thin Film Deposition

- How are thin films deposited? A Guide to PVD vs. CVD Methods for Your Application

- What color diamonds are CVD? Understanding the Process from Brown Tint to Colorless Beauty