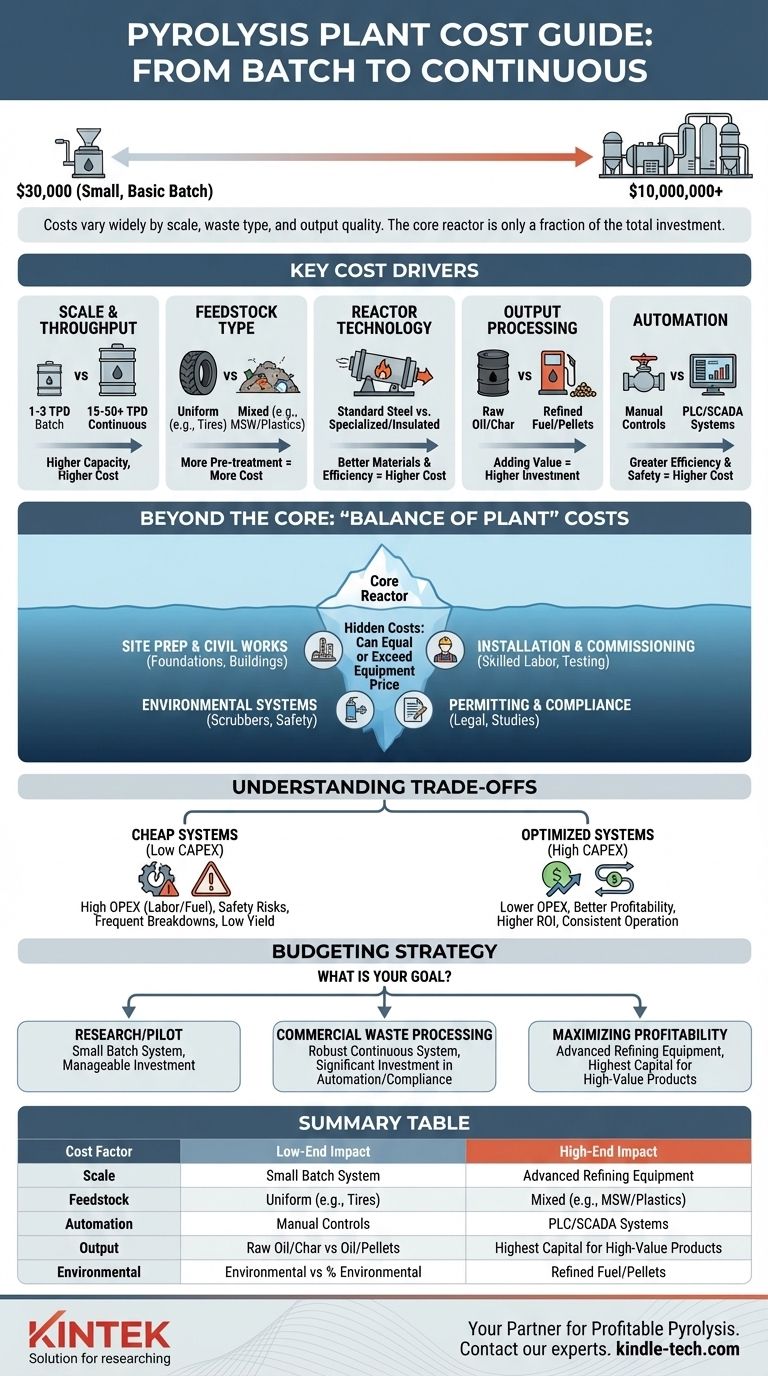

To be direct, a pyrolysis plant can cost anywhere from $30,000 for a very small, basic batch system to well over $10,000,000 for a large-scale, fully automated continuous plant with advanced environmental controls and output refining capabilities. This enormous range exists because the "pyrolysis plant" is not a single product but a complex, integrated system. The final price is determined by its scale, the type of waste it processes, and the quality of the final products it's designed to create.

The core takeaway is that the cost of the central pyrolysis reactor is often only a fraction of the total project investment. The true cost is driven by the supporting infrastructure: feedstock preparation, output processing, environmental compliance, and automation.

The Key Cost Drivers of a Pyrolysis Plant

Understanding the final price requires breaking down the components that contribute to it. The initial quote for the core reactor is merely the starting point of your financial analysis.

Plant Scale and Throughput (Tons Per Day)

The single biggest factor is capacity. A small plant processing 1-3 tons per day uses a batch system, which is manually loaded and unloaded, resulting in lower upfront cost but higher labor needs.

Large commercial operations processing 15, 30, or 50+ tons per day require a continuous system. These are fully automated, far more complex, and represent a significant step-up in capital investment.

Type of Feedstock

The material you intend to process heavily influences the cost of necessary pre-treatment equipment.

A plant designed for uniform scrap tires requires a shredder but is otherwise straightforward. Processing mixed plastics or municipal solid waste (MSW) requires more complex and expensive sorting, shredding, and drying systems to ensure a consistent feedstock.

Pyrolysis Reactor Technology

The heart of the plant, the reactor, varies in design and cost. Rotary kiln reactors, which are common, offer good heat distribution for various feedstocks.

However, the materials used (e.g., standard carbon steel vs. specialized stainless steel for corrosive materials), insulation quality, and heating efficiency all impact the final price and long-term operational costs.

Downstream Output Processing

A basic plant simply condenses pyrolysis gas into a raw, heavy oil and separates out carbon black and steel. This is the cheapest configuration.

Generating higher-value products requires significant additional investment. This includes distillation systems to refine the oil into diesel-like fuel, and grinding and pelletizing equipment to upgrade the carbon black into a saleable commodity.

Automation and Control Systems

A simple plant may rely on manual valves and basic temperature gauges. This minimizes upfront cost but increases labor requirements and the risk of operator error.

A sophisticated plant uses a Programmable Logic Controller (PLC) or SCADA system to automate the entire process. This increases the initial investment but improves efficiency, safety, and consistency while reducing long-term labor costs.

Beyond the Core Equipment: "Balance of Plant" Costs

Many underestimate the costs associated with everything except the primary pyrolysis machinery. These are often referred to as "Balance of Plant" and can easily equal or exceed the equipment cost itself.

Site Preparation and Civil Works

This includes land acquisition, grading, concrete foundations for heavy equipment, and the construction of buildings or shelters to house the plant and store materials.

Environmental and Safety Systems

This is a non-negotiable and significant expense. It includes the flue gas desulfurization and dust removal systems (scrubbers) required to meet air quality regulations. It also covers mandatory fire suppression systems, gas detection alarms, and emergency shutdown mechanisms.

Installation and Commissioning

The cost is not just for the equipment but for the skilled engineers and technicians to install, test, and commission it. For large international projects, this includes travel, lodging, and labor costs over several weeks or months.

Permitting and Regulatory Compliance

Securing the necessary environmental and operational permits can be a lengthy and expensive process involving consultants, environmental impact studies, and legal fees. This cost is highly dependent on local and national regulations.

Understanding the Trade-offs: Cost vs. Viability

A low upfront price can be tempting, but it often conceals long-term expenses and operational risks that can render a project unprofitable.

The Pitfall of "Cheap" Systems

Extremely low-cost systems, often from suppliers with little track record, frequently suffer from poor-quality steel, inefficient heating, and inadequate safety features. This leads to frequent breakdowns, low product yield, and significant safety hazards.

Operational Costs (OPEX) vs. Capital Costs (CAPEX)

A cheaper plant (low CAPEX) may have poor insulation and an inefficient design, leading to much higher fuel consumption (high OPEX). Investing more upfront in a well-engineered, automated system can drastically reduce ongoing labor and energy costs, leading to better profitability.

Revenue vs. Complexity

Investing in oil distillation or carbon black processing equipment increases CAPEX significantly. However, these refined products command a much higher market price than raw pyrolysis oil or char, potentially shortening the payback period and increasing the project's overall ROI.

How to Determine the Right Budget for Your Project

Your budget should be directly aligned with your business objectives. A detailed feasibility study is essential before committing to any purchase.

- If your primary focus is small-scale research or a local pilot program: A smaller, manually operated batch system is likely sufficient and keeps the initial investment manageable.

- If your primary focus is commercial waste tire or plastic processing: You must budget for a robust, continuous system with significant investment in pre-processing, automation, and environmental controls to ensure reliable and compliant operation.

- If your primary focus is maximizing profitability: Your budget must include capital for advanced downstream refining equipment, as creating high-value end products is the key to strong financial returns.

Ultimately, defining your operational goals and understanding every associated cost factor is the foundation for building a successful and profitable pyrolysis operation.

Summary Table:

| Cost Factor | Low-End Impact | High-End Impact |

|---|---|---|

| Scale & Throughput | Batch system (1-3 TPD) | Continuous, automated (15-50+ TPD) |

| Feedstock Type | Uniform (e.g., tires) | Mixed (e.g., MSW, plastics) |

| Automation | Manual controls | PLC/SCADA systems |

| Output Processing | Raw oil/char | Refined fuel, pelletized carbon black |

| Environmental Systems | Basic | Advanced scrubbers, compliance |

| Total Project Cost | ~$30,000 - $200,000 | $1,000,000 - $10,000,000+ |

Ready to build a profitable pyrolysis operation? The right equipment is the foundation of your success. KINTEK specializes in providing robust, efficient pyrolysis reactors and integrated systems tailored to your specific feedstock and output goals. Our expertise helps you navigate the complexities of scale, automation, and environmental compliance to maximize your ROI. Don't let hidden costs undermine your project—contact our experts today for a personalized consultation and quote. Let KINTEK be your partner in turning waste into valuable resources.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What is the function of sputter coater? Achieve Superior Thin Film Deposition for SEM & Electronics

- What is the primary purpose of a condenser in EODS experiments? Prevent Volatilization and Ensure Data Accuracy

- How does heat treatment affect material? Transform Properties for Superior Performance

- Why is ultrasonic treatment essential for PAAMP-b-PVK synthesis? Achieve Surfactant-Free Emulsion Polymerization

- What is the maintenance of laboratory equipment? Ensure Data Integrity and Extend Equipment Lifespan

- What is the desired range of chamber pressure to start the sputtering process? Optimize Your Deposition for Quality and Uniformity

- What is the purpose of using heat treatment? Tailor Material Properties for Superior Performance

- What are the challenges of welding stainless steel? Overcome Warping, Sensitization, and Contamination