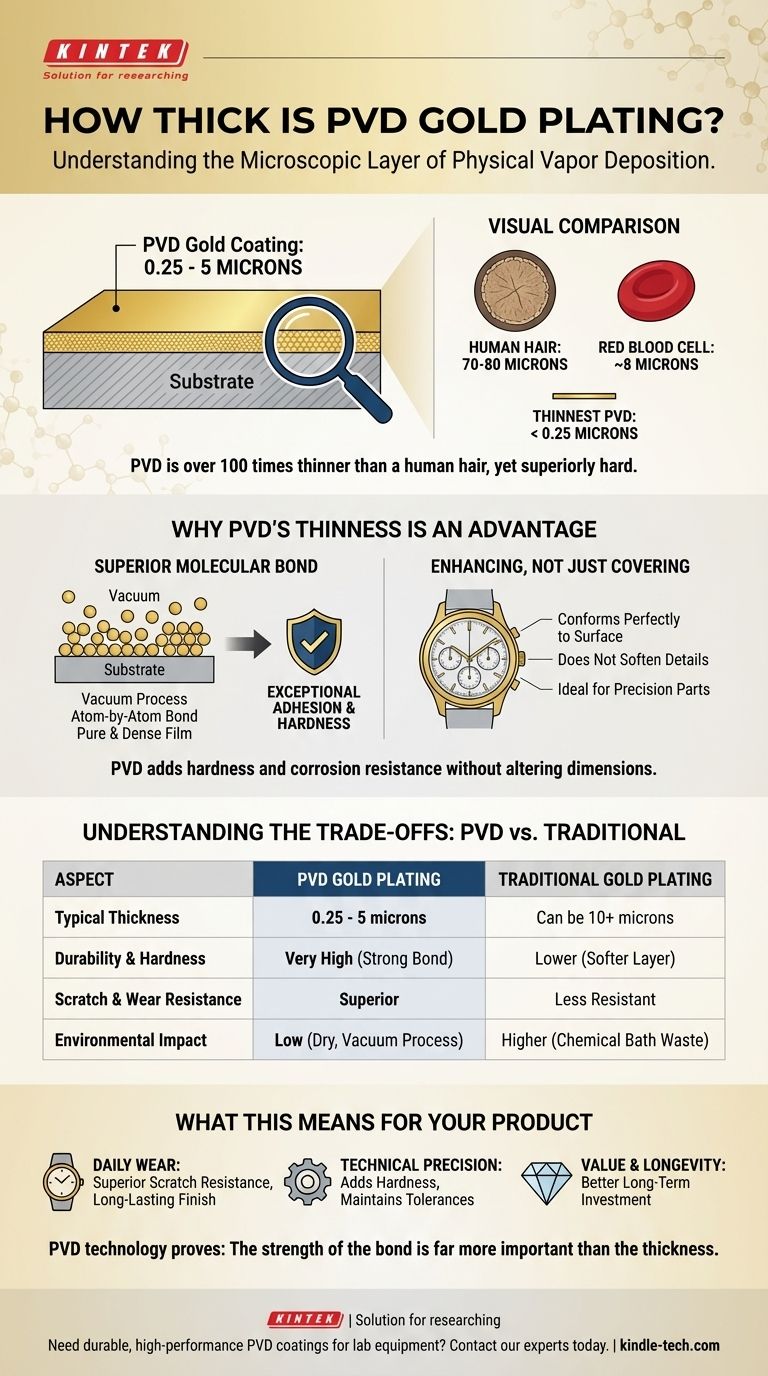

In most applications, PVD (Physical Vapor Deposition) gold plating is between 0.25 and 5 microns thick. This microscopic layer is exceptionally thin, yet the advanced PVD process creates a coating that is significantly harder and more durable than traditional gold plating.

The critical insight is that PVD's value comes from the quality of its molecular bond, not the thickness of the layer. This thin, dense, and hard-wearing film provides superior longevity and scratch resistance compared to thicker but softer traditional plating methods.

Putting PVD Thickness in Context

To understand the scale of PVD coatings, we must first understand the unit of measurement: the micron (μm). A micron is one-millionth of a meter.

The Standard Range

PVD gold coatings typically fall within a range of 0.25 to 5 microns. While this sounds small, the specific thickness is engineered for the product's intended use.

Decorative applications may use a thinner layer (around 0.3 to 1.0 microns), while components subject to high wear, like watch cases, often receive a thicker coating (2 to 5 microns) for maximum durability.

A Visual Comparison

To put this into perspective, consider these comparisons:

- A single human hair is about 70-80 microns thick.

- A red blood cell is approximately 8 microns in diameter.

- The thinnest PVD coating is over 100 times thinner than a human hair.

This extreme thinness is a deliberate feature of the technology.

Why PVD's Thinness Is an Advantage

The effectiveness of a PVD coating is not measured in its bulk but in the quality of its application. The process itself is what sets it apart.

A Superior Molecular Bond

Unlike electroplating, which deposits a softer layer of metal on a surface, PVD works in a vacuum. It vaporizes solid gold and bonds it to the base material atom by atom.

This creates an incredibly pure, dense, and uniform film with exceptional adhesion. The coating becomes an integrated part of the surface rather than just a layer sitting on top.

Enhancing, Not Just Covering

Because the PVD layer is so thin, it conforms perfectly to the original surface without softening details or changing dimensions.

This makes it ideal for precision-engineered items like watch parts, where even a tiny change in tolerance could affect performance. The coating adds hardness and corrosion resistance without altering the part's specifications.

Understanding the Trade-offs: PVD vs. Traditional Plating

Choosing between PVD and traditional plating involves understanding the fundamental difference between thickness and durability.

Thickness is Not Durability

Traditional gold plating can be much thicker, sometimes 10 microns or more. However, this plated layer is made of soft gold and is prone to scratching and wearing away.

A PVD gold coating, despite being thinner, is significantly harder and more resistant to abrasion and tarnishing because of its dense, bonded structure. It retains its color and finish far longer under daily wear.

The Environmental Factor

PVD is a dry, vacuum-based process that is dramatically cleaner than traditional electroplating.

Electroplating involves a chemical bath that produces hazardous waste. PVD, by contrast, is an environmentally friendly technology, a factor that is increasingly important in modern manufacturing.

What This Means for Your Product

The right coating depends entirely on your priority. PVD excels where durability, precision, and longevity are the primary goals.

- If your primary focus is daily wear and tear (e.g., a watch or jewelry): PVD provides superior scratch resistance and color fastness, making it the ideal choice for items you want to look new for years.

- If your primary focus is technical precision (e.g., a high-end component): PVD's ability to add hardness without altering dimensions is a critical advantage that traditional plating cannot offer.

- If your primary focus is value and longevity: PVD-coated products offer a better long-term investment, as their finish will outlast traditionally plated alternatives many times over.

Ultimately, PVD technology proves that the strength of the bond is far more important than the thickness of the coating.

Summary Table:

| Aspect | PVD Gold Plating | Traditional Gold Plating |

|---|---|---|

| Typical Thickness | 0.25 - 5 microns | Can be 10+ microns |

| Durability & Hardness | Very High (due to strong molecular bond) | Lower (softer layer) |

| Scratch & Wear Resistance | Superior | Less Resistant |

| Environmental Impact | Low (dry, vacuum-based process) | Higher (chemical bath waste) |

Need a durable, high-performance coating for your laboratory equipment or components? At KINTEK, we specialize in advanced PVD solutions that enhance the longevity and performance of your lab equipment and consumables. Our coatings provide exceptional hardness and corrosion resistance without compromising precision. Contact our experts today to find the perfect PVD coating solution for your specific laboratory needs!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- Why is PECVD environment friendly? Understanding the Eco-Friendly Benefits of Plasma-Enhanced Coating

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings