Yes, a PVD finish is exceptionally durable. It is one of the most resilient and long-lasting surface coatings available today. The process of Physical Vapor Deposition (PVD) creates a thin film that bonds to the substrate at a molecular level, resulting in a finish that is significantly harder and more corrosion-resistant than traditional methods like electroplating or powder coating.

The core reason for PVD's durability is the process itself. It doesn't just apply a layer of paint; it physically fuses a new, harder surface onto the base material, creating a finish that is highly resistant to scratches, tarnishing, and daily wear.

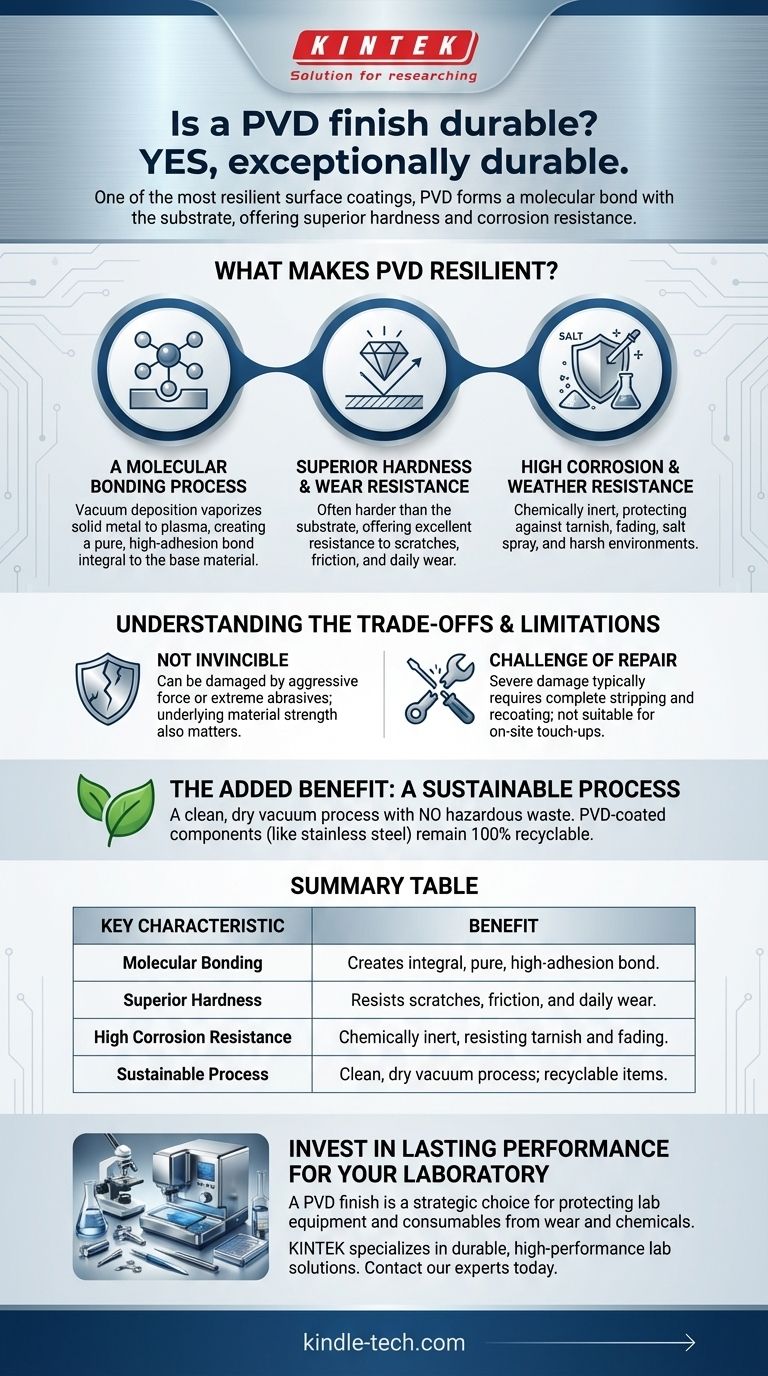

What Makes a PVD Finish So Resilient?

The durability of PVD is not a single characteristic but the result of several factors inherent in the deposition process. It fundamentally changes the surface properties of the object being coated.

A Molecular Bonding Process

PVD is a vacuum coating process that involves vaporizing a solid metal to a plasma of atoms or molecules. This vapor is then deposited onto the object, creating a pure, high-adhesion bond that is extremely difficult to separate.

This method ensures a uniform and dense coating that becomes an integral part of the original item rather than just a superficial layer.

Superior Hardness and Wear Resistance

The resulting PVD coating is often harder than the substrate material itself. This exceptional hardness provides superior resistance to the scratches, friction, and high wear rates common in both functional and decorative applications.

From kitchen faucets to automotive components, this hardness ensures the finish maintains its integrity and appearance through years of use.

High Corrosion and Weather Resistance

PVD coatings are chemically inert and highly resistant to corrosion from salt spray, chemicals, and other environmental factors. This makes them an ideal choice for components exposed to the elements or harsh conditions.

This resistance prevents tarnishing and fading, preserving the original color and luster of the finish far longer than conventional methods.

Understanding the Trade-offs and Limitations

While PVD is a top-tier finish, it's essential to understand its boundaries. No coating is indestructible, and PVD is no exception.

Durability Is Not Invincibility

Despite its high resistance, a PVD coating can be damaged. An aggressive attack with a sharp object or extreme abrasive force can scratch or gouge through the finish.

Think of it as highly scratch-resistant, not entirely scratch-proof. The underlying strength of the base material also plays a role; a PVD coating won't stop a soft metal from denting underneath it.

The Challenge of Repair

One of the most significant trade-offs is repairability. If a PVD finish is severely damaged, it typically cannot be "touched up" or repaired on-site.

The item must be stripped and completely recoated using the same vacuum deposition process, which can be complex and costly.

The Added Benefit: A Sustainable Process

Beyond its performance, the PVD process offers a significant advantage in its environmental impact. It is a clean, dry vacuum process that produces no hazardous waste.

This stands in stark contrast to traditional electrochemical processes like plating, which often involve toxic chemicals. Furthermore, PVD-coated components, such as stainless steel, remain 100% recyclable at the end of their life.

Making the Right Choice for Your Goal

PVD is a premium finishing technology that offers a clear return on investment through longevity and performance.

- If your primary focus is maximum longevity and wear resistance: PVD is one of the best choices available for high-contact items like door hardware, tools, or watches.

- If your primary focus is a lasting decorative finish: PVD provides a stable, vibrant color that resists fading and tarnishing, ensuring aesthetic appeal for years.

- If you are planning for extreme-abuse environments: Acknowledge that while PVD is superior, severe damage is difficult to repair, which may influence your decision.

Ultimately, choosing a PVD finish is a strategic investment in long-term durability and appearance.

Summary Table:

| Key Characteristic | Benefit |

|---|---|

| Molecular Bonding | Creates a pure, high-adhesion bond that is integral to the substrate. |

| Superior Hardness | Provides excellent resistance to scratches, friction, and daily wear. |

| High Corrosion Resistance | Chemically inert, resisting tarnish, fading, and harsh environmental factors. |

| Sustainable Process | A clean, dry vacuum process with no hazardous waste; coated items remain recyclable. |

Invest in lasting performance for your laboratory. A PVD finish is a strategic choice for protecting your valuable lab equipment and consumables from wear, corrosion, and chemical exposure. KINTEK specializes in providing durable, high-performance lab solutions. Contact our experts today to discuss how PVD coatings can enhance the longevity and reliability of your laboratory's critical components.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings