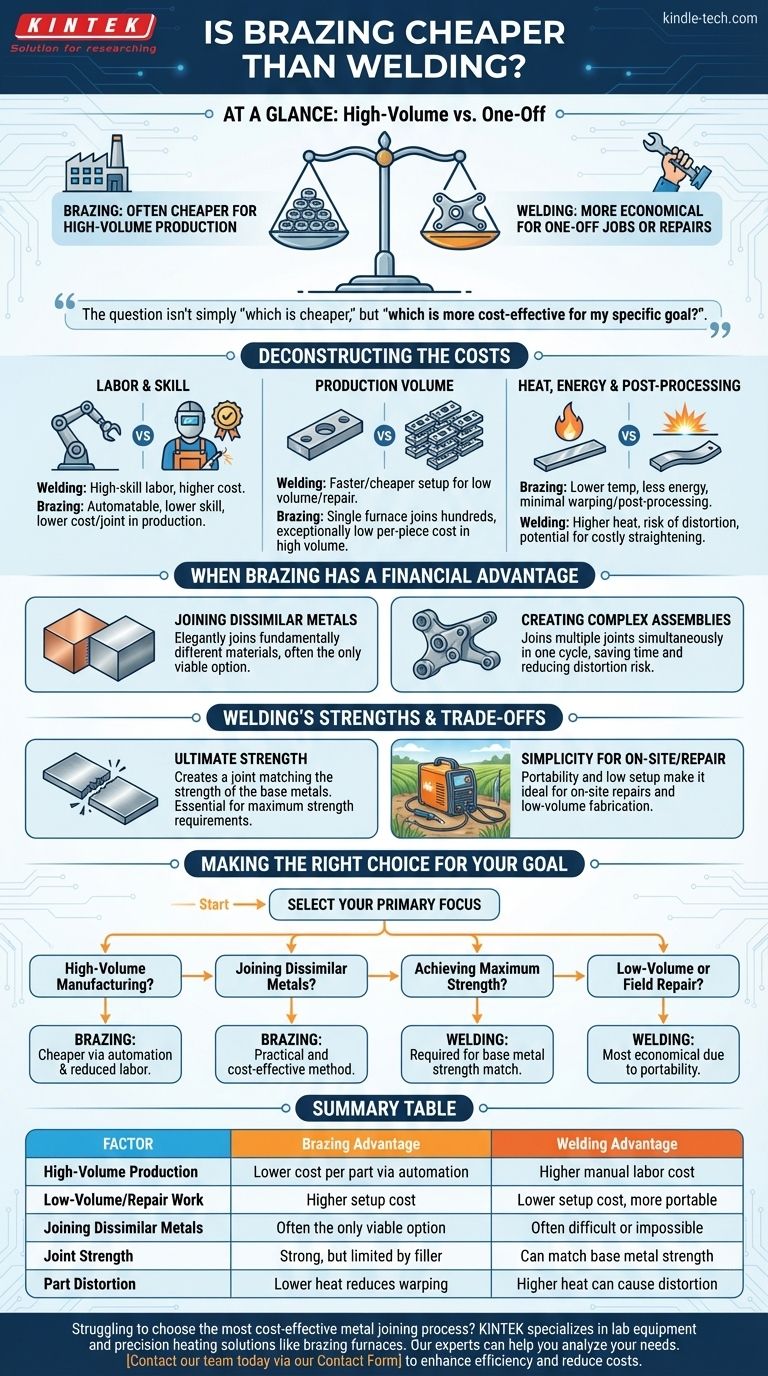

At a glance, brazing is often cheaper than welding for high-volume production, but welding is typically more economical for one-off jobs or repairs. The true cost is not in the process name, but in the specific application, factoring in labor, automation potential, materials, and the required joint performance.

The question isn't simply "which is cheaper," but "which is more cost-effective for my specific goal?" Brazing's main cost advantage lies in its suitability for automation in mass production, while welding's advantage is its flexibility and lower setup cost for manual, low-volume work.

Deconstructing the Costs: Beyond the Initial Price Tag

The final price of joining two metals is a sum of several factors. Understanding these components is the key to making an informed financial decision.

The Role of Labor and Skill

Welding, especially for critical applications, often requires a certified, highly skilled operator, which translates to higher labor costs.

Many brazing processes, such as furnace or induction brazing, can be automated or performed by less-skilled labor, drastically reducing the cost per joint in a production environment.

The Impact of Production Volume

For a single repair or a handful of prototypes, the setup for manual welding is faster and cheaper.

In high-volume manufacturing, brazing excels. A single furnace can join hundreds of complex assemblies at once, making the per-piece cost exceptionally low compared to welding each joint individually.

Heat, Energy, and Post-Processing

Brazing occurs at lower temperatures than welding, meaning it consumes less energy.

This lower heat input also significantly reduces the risk of warping or distorting the base metals, especially on thin parts. This minimizes the need for costly post-joining straightening or machining operations that are common with welding.

When Brazing Presents a Clear Financial Advantage

Certain technical requirements make brazing the more practical and, therefore, more cost-effective choice by default.

Joining Dissimilar Metals

Attempting to weld fundamentally different metals, like copper to steel, is often technically difficult or impossible.

Brazing elegantly solves this problem. It forms a strong metallurgical bond between dissimilar materials, making it the only viable and economical choice for such applications.

Creating Complex Assemblies

If you have a part with multiple joints close together, brazing can join them all simultaneously in a single heating cycle.

Manually welding each of those joints would be far more time-consuming and expensive, increasing the risk of distortion with each pass.

Understanding the Trade-offs: Welding's Strengths

Brazing is not a universal solution. In some scenarios, welding is the superior and more appropriate choice, regardless of cost comparisons.

The Question of Ultimate Strength

A properly executed weld fuses the base metals, creating a joint that can be as strong as the materials themselves.

A brazed joint's strength is limited by the shear strength of the filler metal, which is strong but typically not as strong as the base metals. If maximum strength is the primary design driver, welding is the necessary choice.

Simplicity for On-Site and Repair Work

The portability and minimal setup of common welding processes (like stick or MIG) make them ideal for on-site repairs or low-volume fabrication.

Setting up a controlled atmosphere or induction coil for a single brazing repair is often impractical and cost-prohibitive.

Making the Right Choice for Your Goal

Select your process based on the total cost to achieve your specific operational goal.

- If your primary focus is high-volume manufacturing: Brazing is almost always cheaper due to its massive potential for automation and reduced labor costs.

- If your primary focus is joining dissimilar metals: Brazing is the more practical and cost-effective method, as welding is often not a viable option.

- If your primary focus is achieving maximum joint strength: Welding is the required choice, as it creates a joint that can match the strength of the parent materials.

- If your primary focus is low-volume or field repair work: The low setup cost and portability of manual welding make it the most economical option.

Ultimately, the most cost-effective choice is the one that best aligns with your material, volume, and performance requirements.

Summary Table:

| Factor | Brazing Advantage | Welding Advantage |

|---|---|---|

| High-Volume Production | Lower cost per part via automation | Higher manual labor cost |

| Low-Volume/Repair Work | Higher setup cost | Lower setup cost, more portable |

| Joining Dissimilar Metals | Often the only viable, cost-effective option | Often difficult or impossible |

| Joint Strength | Strong, but limited by filler metal | Can match base metal strength |

| Part Distortion | Lower heat reduces warping risk | Higher heat can cause distortion |

Struggling to choose the most cost-effective metal joining process for your project? KINTEK specializes in lab equipment and consumables, serving laboratory needs with precision heating solutions like brazing furnaces. Our experts can help you analyze your production volume, materials, and performance requirements to determine the optimal, most economical path forward. Contact our team today via our Contact Form to discuss how we can enhance your lab's efficiency and reduce your joining costs.

Visual Guide

Related Products

- Vacuum Heat Treat Sintering Brazing Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- What types of steel can be quenched? A Guide to Hardenable Steels for Optimal Performance

- What is a pyrolysis furnace? A Tool for Converting Waste into Valuable Resources

- What is the brazing process? A Guide to Strong, Permanent Metal Joining

- How do pyrolysis reactor dimensions influence plastic conversion? Optimize Geometry for Higher Liquid Yields

- What are the different types of batch furnace? Find the Right Fit for Your Heat Treating Process

- What are the different types of carburizing? Choose the Right Process for Your Steel Parts

- What role does a high-temperature vacuum furnace play in the pyrolysis stage of C/C-SiC composite manufacturing?

- What is heat treatment as used in metallic materials? Tailor Metal Properties for Superior Performance