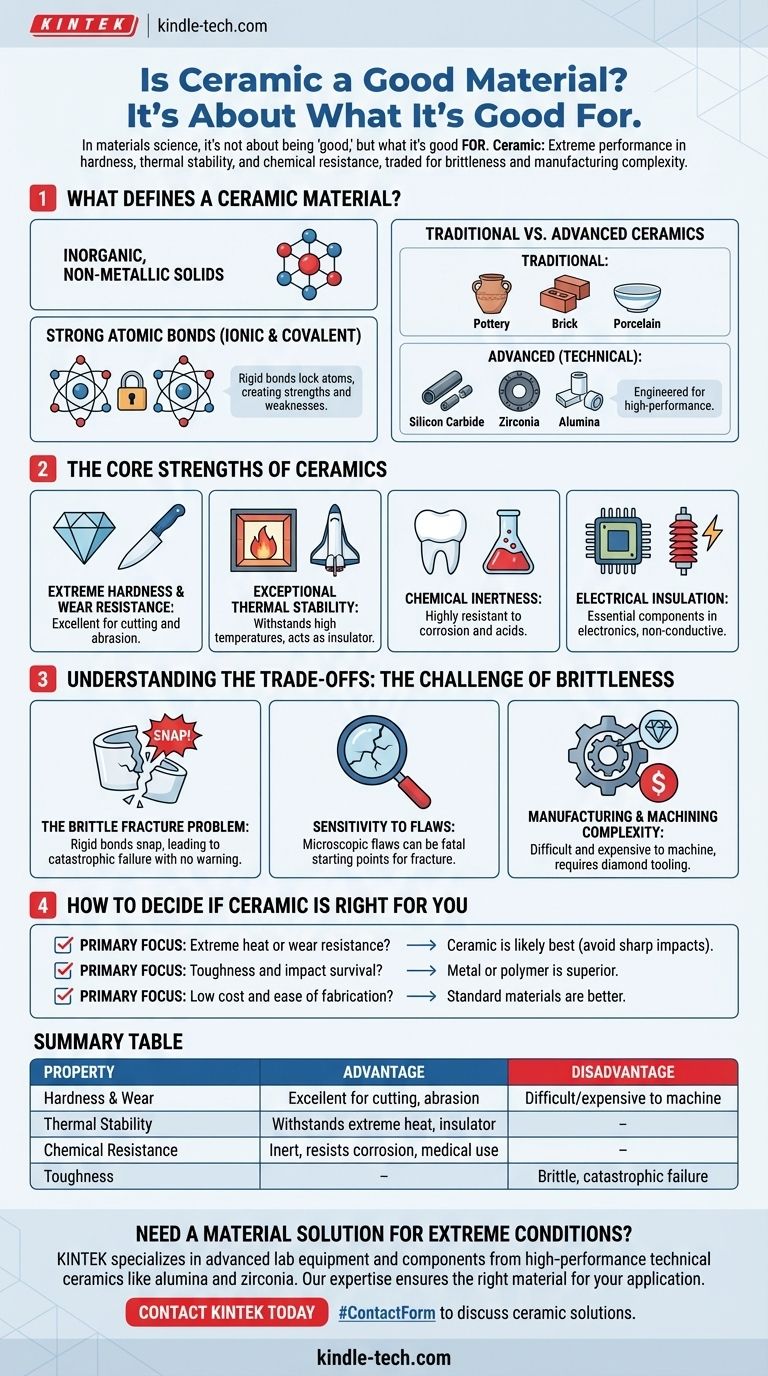

In materials science, the question is never whether a material is "good," but what it is good for. Ceramic is not a single material but a vast class of materials defined by extreme properties. It offers unparalleled performance in hardness, high-temperature stability, and chemical resistance, but this comes at the cost of being inherently brittle and difficult to machine.

The defining characteristic of ceramic is its trade-off: you gain unparalleled performance in hardness and thermal stability at the cost of toughness. Its suitability is entirely dependent on whether your application can tolerate its inherent brittleness and manufacturing complexity.

What Defines a Ceramic Material?

Ceramics are inorganic, non-metallic solids. Their unique properties originate from their atomic structure and the strong chemical bonds holding them together.

The Power of Atomic Bonds

Unlike metals, which have a "sea" of shared electrons that allow atoms to slide past one another (making them ductile), ceramics are held together by extremely strong ionic and covalent bonds. These rigid bonds lock atoms in place, which is the root cause of both ceramic's greatest strengths and its primary weakness.

Traditional vs. Advanced Ceramics

It's critical to distinguish between two main categories. Traditional ceramics include familiar materials like pottery, brick, and porcelain. Advanced or technical ceramics, such as silicon carbide, zirconia, and alumina, are engineered for specific, high-performance applications in aerospace, medicine, and electronics. This guide focuses on the properties of these advanced ceramics.

The Core Strengths of Ceramics

Where metals or polymers fail, ceramics often provide the only viable solution due to their performance at the extremes.

Extreme Hardness and Wear Resistance

Because of their strong atomic bonds, ceramic materials are exceptionally hard and resistant to abrasion and wear. This makes them ideal for applications involving friction or cutting. A ceramic knife, for example, holds its edge far longer than a steel one.

Exceptional Thermal Stability

Ceramics do not melt or deform easily at high temperatures. They also tend to have low thermal conductivity, making them excellent insulators. This is why they are used for everything from furnace linings and engine components to the heat shield tiles on a space shuttle.

Chemical Inertness

Ceramics are highly resistant to chemical corrosion and will not rust or react with most acids and bases. This stability makes them perfect for medical implants like dental crowns and hip joints, as well as for components used in chemical processing plants.

Electrical Insulation

Most ceramics do not conduct electricity, making them essential components in electronics. They serve as substrates for microchips and insulators for high-voltage equipment, preventing short circuits and ensuring reliable performance.

Understanding the Trade-offs: The Challenge of Brittleness

The immense strength of ceramic's atomic bonds is also its Achilles' heel. This rigidity leads directly to its most significant limitation: a lack of toughness.

The Brittle Fracture Problem

When a metal is stressed, it can deform plastically—it bends before it breaks. Ceramic cannot do this. When a crack begins in a ceramic part, the concentrated stress at the crack's tip has nowhere to go. The rigid bonds simply snap, and the crack propagates almost instantaneously, leading to catastrophic failure with no warning.

Sensitivity to Flaws

This brittleness means ceramic components are highly sensitive to pre-existing microscopic flaws, such as tiny voids or cracks introduced during manufacturing. A flaw that would be harmless in a metal part can be a fatal starting point for fracture in a ceramic one.

Manufacturing and Machining Complexity

Because ceramics are so hard, they are extremely difficult and expensive to machine into complex shapes. They are typically formed into their near-final shape and then fired at high temperature (a process called sintering). Any final grinding or polishing requires diamond tooling, adding significant cost and time to production.

How to Decide if Ceramic is Right for You

Your choice must be guided by your primary engineering requirement. You are not choosing a material; you are choosing a specific set of properties to solve a problem.

- If your primary focus is extreme heat or wear resistance: Ceramic is likely the best-in-class material, provided you can design the component to avoid sharp impacts and tensile stress.

- If your primary focus is toughness and impact survival: A metal alloy, a tough polymer, or a composite material will almost always be a superior and safer choice.

- If your primary focus is low cost and ease of fabrication: You should look towards standard metals or polymers unless a specific ceramic property is absolutely non-negotiable.

By understanding this fundamental balance of properties, you can make an informed decision and harness the unique capabilities of ceramic for your specific goal.

Summary Table:

| Property | Advantage | Disadvantage |

|---|---|---|

| Hardness & Wear | Excellent for cutting tools, abrasion resistance | Difficult and expensive to machine |

| Thermal Stability | Withstands extreme heat, excellent insulator | |

| Chemical Resistance | Inert, resists corrosion, ideal for medical/chemical use | |

| Toughness | Brittle, prone to catastrophic failure |

Need a material solution for extreme conditions?

Ceramic's unique properties make it the ideal choice for applications where extreme hardness, thermal stability, or chemical inertness are paramount. If your project demands performance where metals and polymers fail, KINTEK can help.

We specialize in advanced lab equipment and consumables, including components crafted from high-performance technical ceramics like alumina and zirconia. Our expertise ensures you get the right material for your specific application, balancing performance with practical manufacturing considerations.

Contact KINTEK today to discuss how our ceramic solutions can enhance your laboratory's capabilities and reliability.

Visual Guide

Related Products

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- Zirconia Ceramic Gasket Insulating Engineering Advanced Fine Ceramics

- Engineering Advanced Fine Ceramics Head Tweezers with Pointed Elbow Zirconia Ceramic Tip

- Advanced Engineering Fine Ceramics Boron Nitride (BN) Ceramic Parts

- Conductive Boron Nitride BN Ceramics Composite for Advanced Applications

People Also Ask

- Why are ZrO2 grinding jars and balls required for sulfide solid electrolytes? Ensure Purity & Performance

- What are the applications of zirconia ceramics? Unlock High-Performance Solutions for Extreme Environments

- Why are high-purity zirconia grinding balls recommended for LATP ceramic powders? Ensure Purity and High Conductivity.

- Why are zirconia grinding balls recommended for sulfide solid electrolytes? Essential Tips for High Purity Milling

- What are the technical advantages of using zirconia (ZrO2) grinding balls? Enhancing Silicon Composite Anode Performance