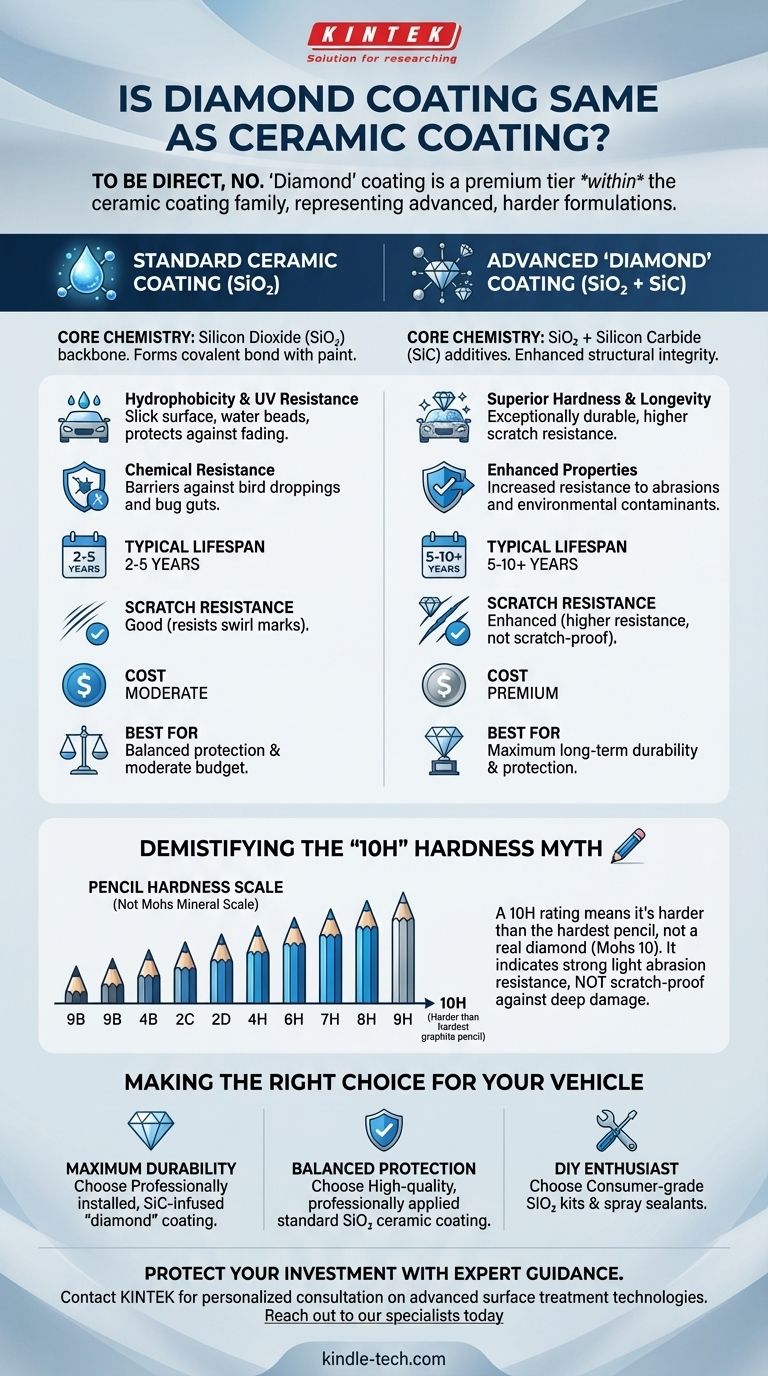

To be direct, no, a "diamond" coating is not the same as a standard ceramic coating. While both serve to protect your vehicle's paint, the term "diamond" is primarily a marketing distinction used to signify a more advanced, durable, and often harder formulation of a ceramic coating. It represents an evolution of the technology, not a fundamentally different category of product.

The critical point to understand is that "diamond" coatings are a premium tier within the ceramic coating family. They build upon the same core silicon dioxide (SiO₂) chemistry but enhance it with additives like silicon carbide (SiC) to achieve superior hardness and longevity, justifying a higher price point.

What is a True Ceramic Coating?

To understand the difference, we must first establish the baseline: the standard ceramic coating.

The Role of Silicon Dioxide (SiO₂)

The backbone of any true ceramic coating is Silicon Dioxide (SiO₂), a liquid polymer that, when applied to your car's clear coat, undergoes a chemical reaction.

This reaction forms a covalent bond with the surface. The result is a semi-permanent, transparent layer of protection that is chemically bonded to your vehicle's paint.

How It Protects Your Paint

This bonded SiO₂ layer provides several key benefits:

- Hydrophobicity: It creates an extremely slick surface that repels water, causing it to bead up and roll off, taking dirt and contaminants with it.

- UV Resistance: It acts as a barrier against the sun's harmful UV rays, preventing paint oxidation and fading.

- Chemical Resistance: It protects the paint from acidic contaminants like bird droppings and bug guts.

Demystifying "Diamond" and Other Advanced Coatings

The term "diamond" entered the market to differentiate new, more robust formulations from standard SiO₂ coatings.

Marketing vs. Chemistry

"Diamond" is an analogy for hardness. These coatings are not made of actual diamond. Instead, the name signifies a product engineered to be harder and more durable than its predecessors.

Think of it as the difference between regular and "extra-strength" medicine. Both are based on the same active ingredient, but one has a higher concentration or additional components for more potent results.

The Key Additive: Silicon Carbide (SiC)

Many top-tier coatings marketed as "diamond," "titanium," or "graphene" gain their enhanced properties from the inclusion of materials like Silicon Carbide (SiC).

SiC is an exceptionally hard and durable compound used in industrial applications like sandpaper and brake discs. When integrated into a ceramic coating formula, it significantly increases the coating's structural integrity and scratch resistance.

The "10H" Hardness Myth

You will often see these advanced coatings advertised with a "10H" hardness rating. It's crucial to understand what this means.

This rating comes from the pencil hardness scale, not the Mohs scale of mineral hardness (where a real diamond is a 10). A 10H rating simply means the cured coating is harder than the hardest graphite pencil. While impressive and indicative of strong scratch resistance against light abrasions (like from washing), it does not mean your car is now scratch-proof.

Understanding the Trade-offs

Choosing a more advanced coating involves balancing cost, longevity, and realistic expectations.

Cost and Professional Application

Advanced SiC-infused coatings are significantly more expensive than standard SiO₂ products. They are also less forgiving to apply.

Their high cost is a function of both the advanced chemistry and the fact that they almost always require meticulous paint correction and professional installation to perform as advertised.

Performance and Longevity

The primary benefit of a "diamond" or SiC-based coating is longevity. A professionally installed advanced coating can last for 5 years, 10 years, or even a "lifetime" with proper maintenance.

A standard, high-quality ceramic coating typically offers a lifespan of 2 to 5 years. Both provide excellent gloss and hydrophobicity, but the advanced version maintains these properties for a longer period.

The Illusion of "Scratch-Proof"

No coating makes your car's paint invulnerable. These coatings provide scratch resistance, primarily against micro-scratches and swirl marks induced by improper washing techniques.

Deep scratches from keys, shopping carts, or automatic car washes with abrasive brushes can still penetrate the coating and damage your clear coat.

Making the Right Choice for Your Vehicle

Your decision should be based on your goals, budget, and how you maintain your vehicle.

- If your primary focus is maximum durability and long-term protection: A professionally installed, SiC-infused "diamond" coating is the superior investment for preserving your vehicle's finish for many years.

- If your primary focus is excellent protection on a moderate budget: A high-quality, professionally applied standard SiO₂ ceramic coating offers 80-90% of the benefits at a significantly lower cost.

- If you are a DIY enthusiast seeking enhanced protection: Consumer-grade SiO₂ kits and ceramic-infused spray sealants are excellent options that provide great results, though with less durability than professional products.

By focusing on the underlying chemistry rather than the marketing names, you can confidently select the right level of protection for your vehicle.

Summary Table:

| Feature | Standard Ceramic Coating | Advanced 'Diamond' Coating |

|---|---|---|

| Core Chemistry | Silicon Dioxide (SiO₂) | SiO₂ + Silicon Carbide (SiC) additives |

| Primary Benefit | Excellent hydrophobicity & UV resistance | Superior hardness & longevity |

| Typical Lifespan | 2-5 years | 5-10+ years |

| Scratch Resistance | Good (resists swirl marks) | Enhanced (higher scratch resistance) |

| Cost | Moderate | Premium |

| Best For | Balanced protection & budget | Maximum long-term durability |

Protect Your Investment with the Right Coating

Choosing the perfect paint protection can be complex. Our experts at KINTEK are here to help you navigate the options. We specialize in advanced surface treatment technologies and can provide insights tailored to your vehicle's needs.

Why contact KINTEK?

- Expert Guidance: Get clear, unbiased advice on ceramic vs. diamond coatings.

- Quality Assurance: We connect you with professional-grade solutions for lasting results.

- Tailored Solutions: Whether you're a car enthusiast or a detailing professional, we help you achieve superior gloss and protection.

Don't leave your vehicle's finish to chance. Reach out to our specialists today for a personalized consultation and discover how the right coating can keep your car looking showroom-fresh for years to come.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- Precision Machined Zirconia Ceramic Ball for Engineering Advanced Fine Ceramics

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Boron Nitride (BN) Crucible for Phosphorous Powder Sintered

- Engineering Advanced Fine Ceramics Head Tweezers with Pointed Elbow Zirconia Ceramic Tip

People Also Ask

- Is diamond coating permanent? The Truth About Its Long-Lasting Durability

- Is diamond coating worth it? Maximize Component Life and Performance

- What is CVD diamond coating? Grow a Super-Hard, High-Performance Diamond Layer

- How long does diamond coating last? Maximize Lifespan with the Right Coating for Your Application

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose