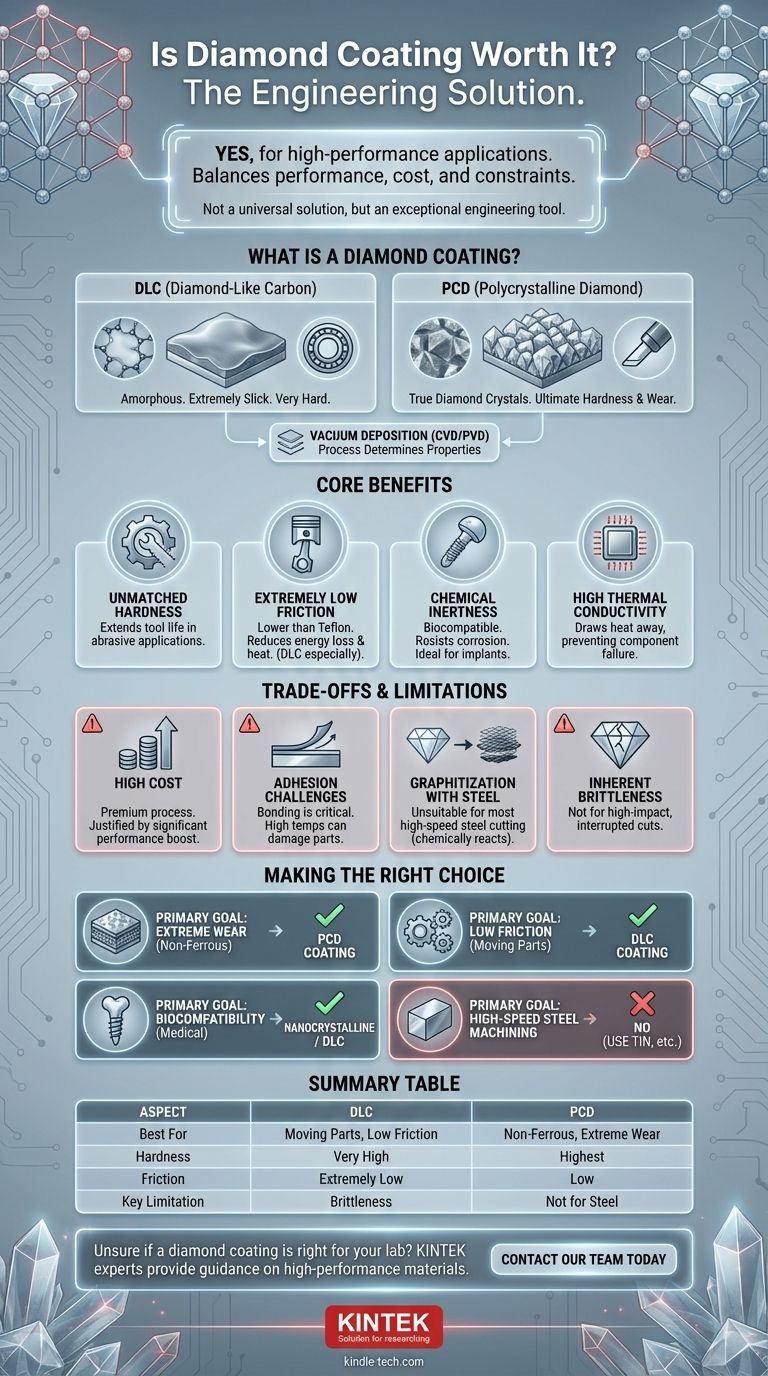

In many high-performance applications, yes, a diamond coating is absolutely worth the investment. It provides an unparalleled combination of hardness, wear resistance, and low friction that can dramatically extend the life and improve the efficiency of critical components. However, its value is entirely dependent on the specific application, the type of coating used, and a clear understanding of its limitations.

The question isn't whether diamond coatings are "good"—their material properties are exceptional. The real question is whether a diamond coating is the correct engineering solution for your specific problem, balancing its high performance against significant cost and application constraints.

What Exactly Is a "Diamond Coating"?

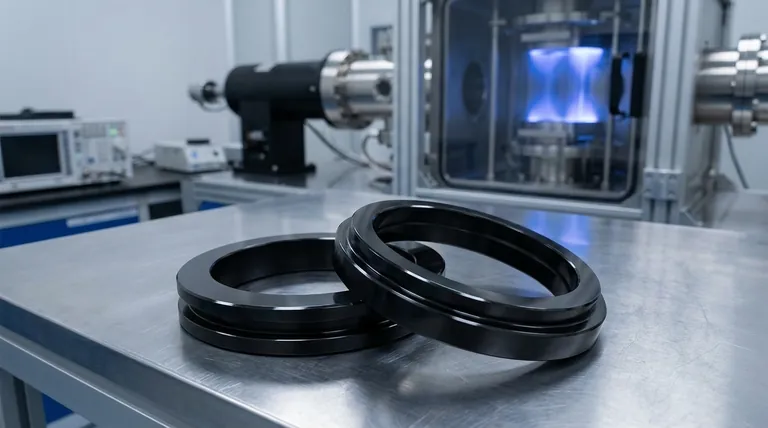

Many people hear "diamond coating" and imagine a simple layer of protection. The reality is a highly technical materials science process where a thin film of carbon with diamond-like properties is grown directly onto the surface of a substrate.

The Two Main Categories

Not all diamond coatings are the same. They generally fall into two major families, each suited for different tasks.

- Diamond-Like Carbon (DLC): This is an amorphous carbon coating, meaning its atoms lack a rigid crystal structure. It contains a mixture of diamond (sp³) and graphite (sp²) bonds, creating a surface that is extremely hard and exceptionally slick.

- Polycrystalline Diamond (PCD): This is a film of "true" diamond. It consists of countless microscopic diamond crystals bonded together on the substrate's surface. This type offers the ultimate in hardness and wear resistance, closely mimicking solid diamond.

The Process Determines the Properties

These coatings are applied using sophisticated vacuum deposition techniques, such as Chemical Vapor Deposition (CVD) or Physical Vapor Deposition (PVD). The specific method used is critical, as it dictates the coating's adhesion, thickness, and final properties.

The Core Benefits of Diamond Coatings

Engineers specify these advanced coatings to solve some of the most demanding physical challenges.

Unmatched Hardness and Wear Resistance

This is the most well-known benefit. A diamond-coated cutting tool can last orders of magnitude longer than an uncoated one when machining abrasive materials like carbon fiber composites, graphite, or high-silicon aluminum.

Extremely Low Friction

DLC coatings, in particular, have a coefficient of friction lower than Teflon. This "lubricity" is critical for high-performance moving parts, such as in racing engines or precision gears, where it reduces energy loss and heat generation.

Chemical Inertness and Biocompatibility

Diamond is chemically stable and does not react with most acids or corrosive agents. This property, combined with its hardness, makes it an ideal coating for medical implants like artificial joints, preventing degradation and ensuring compatibility with the human body.

High Thermal Conductivity

True diamond coatings are excellent thermal conductors. This allows them to quickly draw heat away from a critical point, such as the tip of a cutting tool or a high-power electronic component, preventing overheating and failure.

Understanding the Trade-offs and Limitations

A diamond coating is not a universal solution. Its effectiveness is constrained by very real technical and financial limitations.

The Cost Factor

This is a premium, specialized process. The equipment is expensive, and the process requires significant expertise. The cost must be justified by a substantial increase in performance or component lifespan.

Adhesion and Substrate Compatibility

Properly bonding a diamond film to a substrate is the single greatest technical challenge. If the adhesion is poor, the coating can flake or peel off under stress. Furthermore, the high temperatures required for some CVD processes can damage or distort the underlying part.

The "Graphitization" Problem with Steel

This is a critical limitation. At the high temperatures generated when machining steel, the diamond coating can react with the iron, converting the diamond (hard) back into graphite (soft). This makes diamond coatings unsuitable for most high-speed steel cutting applications.

Inherent Brittleness

While incredibly hard, diamond is also a brittle material. Diamond coatings do not handle high-impact, interrupted cuts as well as tougher (but less hard) coatings like Titanium Nitride (TiN).

Making the Right Choice for Your Application

To determine if a diamond coating is worth it, you must align its properties with your primary goal.

- If your primary focus is extreme wear resistance for non-ferrous materials: A PCD coating is an excellent choice for machining composites, ceramics, or aluminum alloys.

- If your primary focus is reducing friction and wear in moving parts: A DLC coating is a superior solution for components like bearings, gears, and piston rings.

- If your primary focus is biocompatibility for medical devices: Specially prepared nanocrystalline diamond and DLC coatings are the industry standard for improving the longevity of implants.

- If your primary focus is high-speed machining of steel or stainless steel: A diamond coating is likely the wrong choice; consider alternatives like TiN, TiAlN, or other ceramic coatings instead.

Ultimately, the worth of a diamond coating is unlocked by precisely matching its unique properties to a specific and demanding engineering challenge.

Summary Table:

| Aspect | Diamond-Like Carbon (DLC) | Polycrystalline Diamond (PCD) |

|---|---|---|

| Best For | Low friction, moving parts | Extreme wear, non-ferrous materials |

| Hardness | Very High | Highest |

| Friction | Extremely Low | Low |

| Key Limitation | Brittleness | Not suitable for machining steel |

Unsure if a diamond coating is the right solution for your lab equipment or components? KINTEK specializes in providing advanced lab equipment and consumables, including guidance on high-performance coatings. Our experts can help you determine if a diamond coating will deliver the durability and efficiency your application demands. Contact our team today to optimize your lab's performance with the right materials science solution.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- CVD Diamond Dressing Tools for Precision Applications

- CVD Diamond Domes for Industrial and Scientific Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- CVD Diamond Cutting Tool Blanks for Precision Machining

People Also Ask

- How is graphene made and what is the process? A Guide to Top-Down vs. Bottom-Up Methods

- What are 2 properties of carbon nanotubes that make it special? Unmatched Strength & Conductivity

- Is carbon nanotube a good conductor of electricity? Unlocking Superconductivity at the Nanoscale

- What is the function of a sputtering target? The Key to High-Quality Thin-Film Deposition

- How does chirality affect carbon nanotubes? It Determines If They Are Metal or Semiconductor

- What is the effect of thickness of thin film? Master Optical, Electrical, and Mechanical Properties

- What is CVD lab grown diamond? A Real Diamond Grown in a Lab

- What are the growth processes of thin films? Master the 3 Modes for Precise Material Engineering