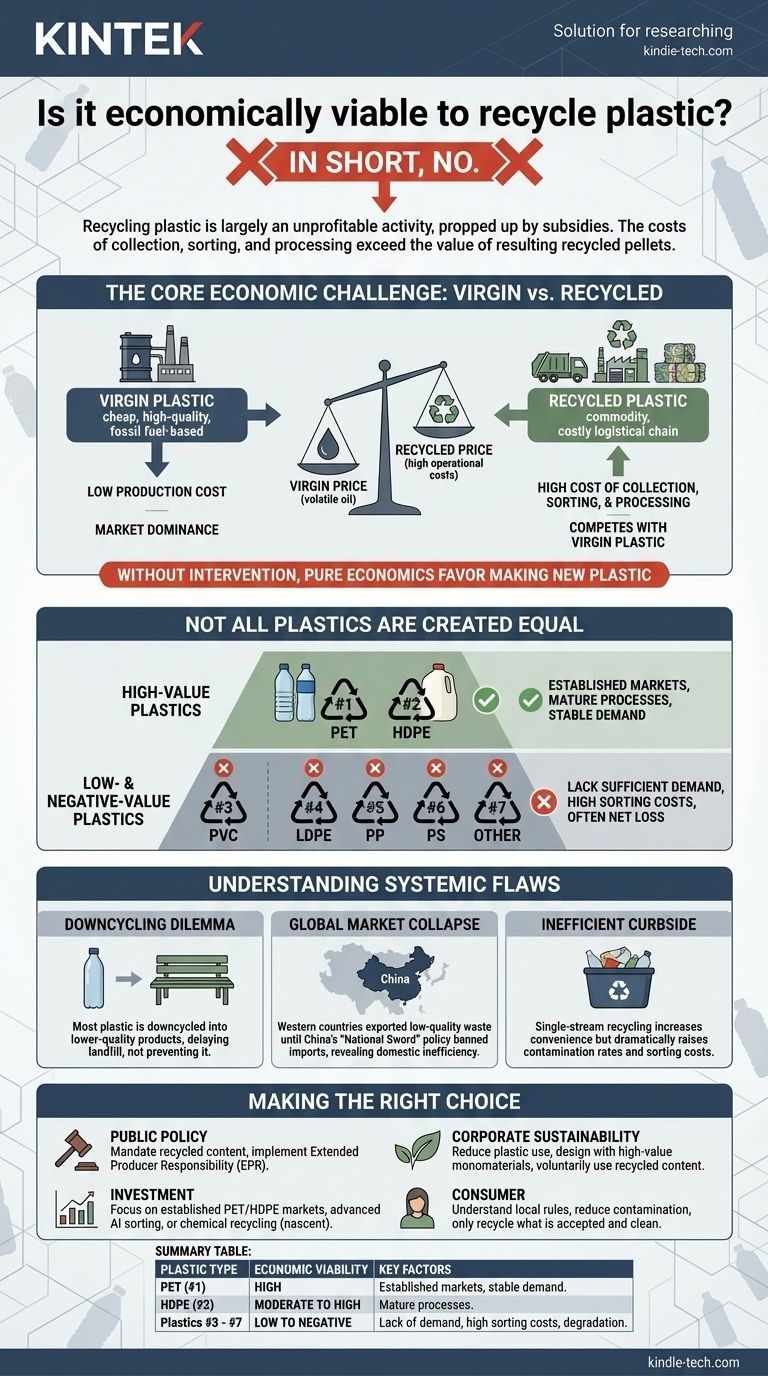

In short, no. The economic viability of recycling plastic is not guaranteed; it is a fragile and conditional outcome. For most types of plastic, recycling is an unprofitable activity that is propped up by municipal funds and subsidies, largely because the cost of collecting, sorting, and processing the material is greater than the value of the resulting plastic pellets, which must compete with cheap, high-quality virgin plastic made from fossil fuels.

The profitability of plastic recycling is the exception, not the rule. It hinges on a complex interplay of volatile oil prices, the specific type of plastic, the level of contamination, and the sophistication of local infrastructure. Without significant policy intervention or technological breakthroughs, the pure economics favor making new plastic over recycling old.

The Core Economic Challenge: Virgin vs. Recycled

The fundamental problem is that recycled plastic is a commodity that must compete in a market dominated by its brand-new counterpart: virgin plastic.

The Overwhelming Influence of Oil Prices

Virgin plastic is a direct byproduct of crude oil and natural gas. When oil prices are low, the cost to produce new, high-quality plastic plummets.

This creates a ceiling on the price that buyers are willing to pay for recycled plastic pellets, which are often of lower quality. If recycled material is more expensive than virgin material, manufacturers have no economic incentive to use it.

The High Cost of Collection and Sorting

Recycling isn't a single action; it's a long, expensive logistical chain. Municipalities or their contractors must pay for trucks, fuel, and labor to collect materials from millions of homes.

These materials are then transported to a Material Recovery Facility (MRF), which uses a combination of manual labor and complex machinery to separate plastics from paper, metal, and glass, and then to sort the different types of plastic from each other. This is a costly, energy-intensive process.

The Problem of Contamination

A single dirty container can contaminate an entire bale of plastics. Food residue, liquids, and non-recyclable items (known as "wishcycling") tossed into recycling bins increase processing costs and dramatically lower the quality and value of the final material.

A clean, pure stream of a single type of plastic can be valuable. A contaminated, mixed-plastic stream can be worthless, costing more to landfill than it could ever be sold for.

Not All Plastics Are Created Equal

The number inside the recycling symbol is not a guarantee of recyclability; it's a resin identification code. The economic viability differs drastically between these numbers.

The High-Value Plastics: PET (#1) and HDPE (#2)

Polyethylene terephthalate (PET #1), used in water bottles and soda bottles, and high-density polyethylene (HDPE #2), used in milk jugs and detergent containers, are the workhorses of the recycling world.

These plastics have established, stable end-markets for products like new containers, textiles, and building materials. Their recycling processes are mature, and they consistently hold enough value to make their collection and reprocessing economically feasible, or at least close to it.

The Low- and Negative-Value Plastics: #3 - #7

Most other plastics, including PVC (#3), LDPE (#4), PP (#5), and Polystyrene (#6), are rarely profitable to recycle.

These materials are technically recyclable, but they lack sufficient end-market demand. They are difficult to sort, their material properties can degrade significantly after recycling, and the cost of processing them almost always exceeds their final market value. For MRFs, these plastics are often a net loss.

Understanding the Trade-offs and Systemic Flaws

The popular conception of recycling often hides critical inefficiencies and harsh realities that undermine its economic and environmental goals.

The "Downcycling" Dilemma

Most plastic is not truly recycled in a closed loop (a bottle becoming a new bottle). Instead, it is downcycled into a lower-quality product, such as carpet fiber, park benches, or fleece jackets.

This process still requires a constant input of virgin plastic to create new high-quality products like food-grade containers. Downcycling delays the plastic's journey to the landfill but doesn't prevent it.

The Hidden Costs of Global Markets

For decades, Western countries exported their low-quality, contaminated plastic waste to China and other nations. This created a false sense of recycling success and hid the true cost.

In 2018, China's "National Sword" policy banned these imports, causing the global market for waste plastic to collapse. This event forced domestic recycling systems to confront the reality that their operations were not economically self-sufficient.

The Inefficiency of Curbside Systems

Single-stream curbside recycling, where all materials are placed in one bin, is convenient for consumers but disastrous for material quality. The mixing of paper, glass, and plastics leads to high rates of contamination.

Glass shards embed in plastic bales, and wet paper waste soils everything. This significantly increases sorting costs and reduces the final value of all the collected commodities.

Making the Right Choice for Your Goal

Improving the economics of plastic recycling requires a systemic shift, not just individual action. The focus must be on creating a stable system where recycled materials can compete.

- If your primary focus is public policy: Prioritize creating stable, non-negotiable demand for recycled materials through recycled content mandates and implementing Extended Producer Responsibility (EPR) schemes that make manufacturers financially responsible for their packaging's end-of-life.

- If your primary focus is corporate sustainability: First, reduce plastic use outright. Second, design products using only high-value, easily recycled monomaterials like PET or HDPE. Third, voluntarily use recycled content in your packaging to help strengthen the market.

- If your primary focus is investment: The safest bets are in the established PET and HDPE reprocessing markets. More speculative but potentially high-reward areas include advanced AI-driven sorting technologies and chemical recycling, though the latter is still nascent and energy-intensive.

- If your primary focus is as a consumer: Understand your local recycling rules and follow them perfectly. Your goal is to reduce contamination by only recycling what is accepted and ensuring it is clean and dry.

Ultimately, the economic viability of plastic recycling is not a natural state; it is a system that must be intentionally designed, funded, and protected from the volatile market forces of virgin materials.

Summary Table:

| Plastic Type (Resin Code) | Economic Viability | Key Factors |

|---|---|---|

| PET (#1) | High | Established markets, stable demand for new containers/textiles. |

| HDPE (#2) | Moderate to High | Mature processes, used in jugs/detergent bottles. |

| Plastics #3 - #7 | Low to Negative | Lack of demand, high sorting costs, material degradation. |

Optimize your laboratory's plastic waste management and material analysis with KINTEK.

As a leading supplier of lab equipment and consumables, we understand the challenges labs face with material sustainability and cost-efficiency. Whether you're researching new polymer blends, analyzing material degradation, or seeking to improve your lab's recycling practices, KINTEK provides the reliable equipment and expertise you need.

Contact our experts today to discuss how our solutions can support your specific laboratory needs and help you make more informed, sustainable choices.

Visual Guide

Related Products

- Custom PTFE Teflon Parts Manufacturer for Cleaning Racks

- Custom Machined and Molded PTFE Teflon Parts Manufacturer for Laboratory ITO FTO Conductive Glass Cleaning Flower Basket

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

People Also Ask

- What are the problems with pyrolysis oil? Key Challenges in Bio-Oil Stability and Cost

- What is the process of thin film coating? A Guide to Precision Layer Deposition

- Why are purge and vent ports necessary for sample reservoirs in fission product simulation systems? Ensure Data Accuracy

- Why must PEO and lithium salt raw materials be pre-treated in a vacuum drying oven? Ensure Battery Stability

- How do high-precision constant temperature shakers facilitate enzymatic hydrolysis? Optimize Glucose Conversion Rates

- What is an alternative to a rotary vacuum evaporator? Find the Right Evaporation Technology for Your Lab

- What is the purpose of a laboratory furnace? Achieve Precise High-Temperature Processing

- What is the effect of residence time on pyrolysis? Control Product Yields from Bio-oil to Biochar