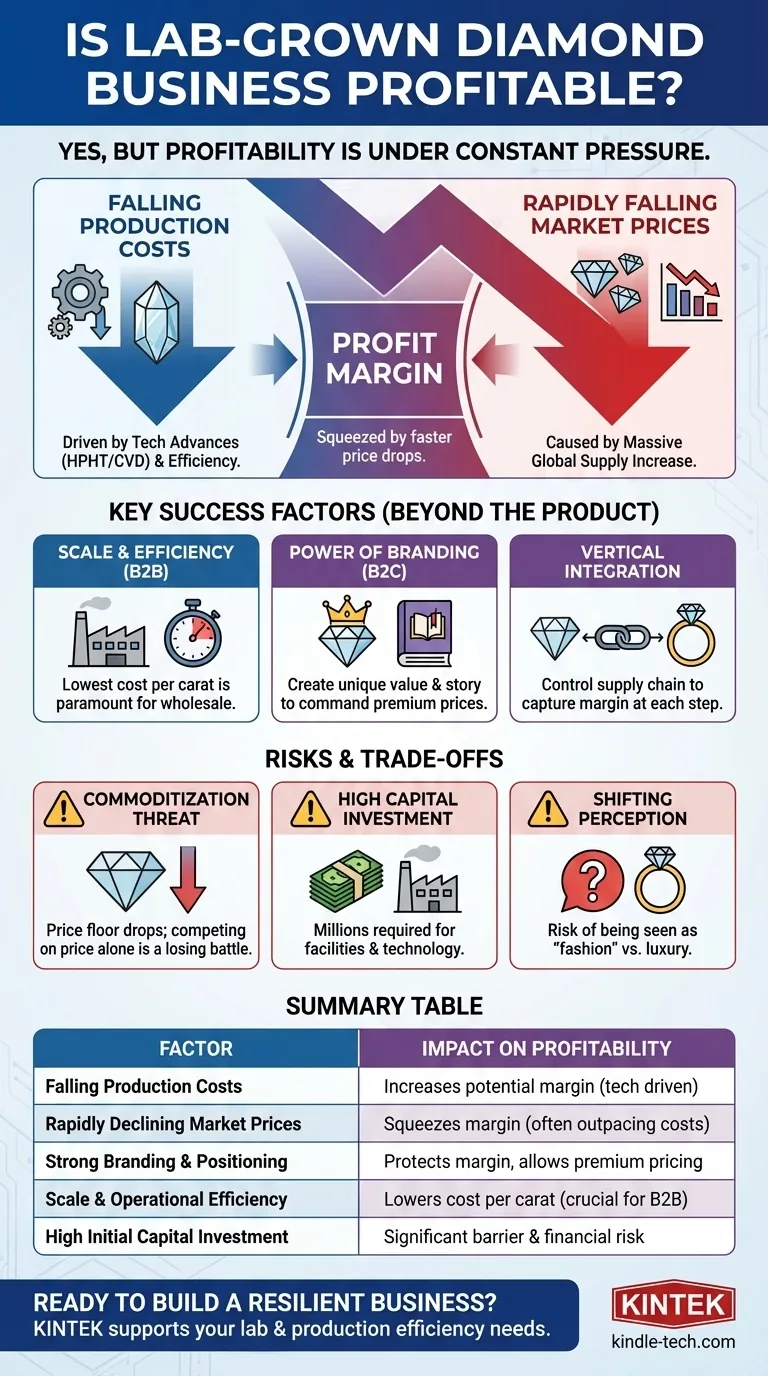

Yes, the lab-grown diamond business can be highly profitable, but this profitability is under constant pressure. The industry is defined by a fundamental tension: while manufacturing technology is becoming more efficient and driving down production costs, a massive increase in global supply is causing market prices for the final product to fall even faster.

The core challenge in the lab-grown diamond business is not just making the diamonds, but managing the margin between rapidly decreasing production costs and even more rapidly plummeting market prices. Profitability now hinges less on manufacturing prowess and more on strategic branding and market positioning.

The Core Profitability Equation: Costs vs. Price

Profit in any industry is the gap between cost and price. In the lab-grown diamond sector, both of these variables are moving targets, creating a dynamic and challenging environment.

Understanding Production Costs

The two dominant manufacturing methods are High Pressure/High Temperature (HPHT) and Chemical Vapor Deposition (CVD).

Both methods have become significantly more efficient over the last decade. Advances in technology, automation, and operational scale mean the cost to produce a carat of lab-grown diamond continues to fall, a trend that is expected to continue.

The Unrelenting Pressure of Falling Prices

This efficiency is a double-edged sword. As more producers enter the market and existing ones scale up, the global supply of lab-grown diamonds has exploded.

This surge in availability has led to rapid price deflation. The wholesale and retail prices of lab-grown diamonds are decreasing at a rate that often outpaces the reduction in production costs, squeezing profit margins for manufacturers and resellers alike.

The Widening Gap with Natural Diamonds

Initially positioned as a direct competitor to natural diamonds, the price gap between the two has grown substantially. This is repositioning lab-grown diamonds in the consumer's mind as a distinct, more accessible product category rather than a simple like-for-like substitute.

Key Factors for a Successful Business Model

In a market characterized by commoditization, achieving profitability requires moving beyond just the product itself. Success is found in business strategy and execution.

Achieving Scale and Efficiency

For businesses focused on the manufacturing side, scale is paramount. Larger, more technologically advanced operations can produce diamonds at a lower cost per carat, which is a critical advantage when competing in a B2B wholesale market.

The Power of Branding

The most successful consumer-facing companies are building strong brands. By creating unique designs, a compelling story (e.g., sustainability, modern love), and a trusted customer experience, they can command higher prices than the unbranded, commoditized alternative.

Controlling the Supply Chain

Vertical integration—where a company controls multiple stages from production to retail—offers another path to profitability. By capturing the margin at each step, these businesses are less vulnerable to price pressure at any single point in the value chain.

Understanding the Trade-offs and Risks

While the opportunity is significant, the financial and market risks are equally real. Anyone considering entering this space must understand the downsides.

The Inevitable Threat of Commoditization

As the technology becomes more widespread, the "floor" for lab-grown diamond prices will continue to drop. For businesses without a strong brand or a significant cost advantage, competing on price alone becomes a losing battle.

High Initial Capital Investment

Setting up a diamond growth facility using HPHT or CVD technology requires millions of dollars in capital expenditure. This represents a significant financial risk, especially given the uncertainty of future pricing.

Shifting Market Perception

There is a risk that as prices continue to fall, consumers may begin to perceive lab-grown diamonds not as a budget-friendly alternative to natural diamonds, but as a semi-precious "fashion" gemstone. This perception would place a firm ceiling on potential prices and margins.

Making the Right Choice for Your Goal

Your business model will determine your path to profitability. There is no single "right" way, only the right strategy for a specific goal.

- If your primary focus is large-scale production (B2B): Your success will depend on achieving the lowest possible cost per carat through superior technology and operational efficiency.

- If your primary focus is a direct-to-consumer brand (B2C): Your profitability will be determined by your ability to create a compelling brand story and unique designs that justify a premium over commodity prices.

- If your primary focus is jewelry retail: Your margin depends on sourcing intelligently in a falling price environment and adding value through expert curation, design, and building trust with your clientele.

Ultimately, profitability in the lab-grown diamond market is shifting from a technological challenge to a classic business challenge of brand building, market differentiation, and operational excellence.

Summary Table:

| Factor | Impact on Profitability |

|---|---|

| Falling Production Costs | Increases potential margin, driven by tech advances (HPHT/CVD). |

| Rapidly Declining Market Prices | Squeezes margin, often outpacing cost reductions. |

| Strong Branding & Positioning | Protects margin, allows for premium pricing. |

| Scale & Operational Efficiency | Lowers cost per carat, crucial for B2B models. |

| High Initial Capital Investment | Significant barrier to entry and financial risk. |

Ready to build a resilient lab-grown diamond business?

The path to profitability hinges on strategic planning and operational excellence. At KINTEK, we understand the precise needs of the laboratory and production environments that underpin this industry. Whether you require specialized equipment for R&D, quality control, or scaling your manufacturing process, our expertise in lab equipment and consumables can help you achieve greater efficiency and control over your costs.

Let's discuss how we can support your venture. Contact our experts today to find the right solutions for your specific goals.

Visual Guide

Related Products

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- CVD Diamond Domes for Industrial and Scientific Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What is the manufacturing process of sintering? A Guide to Solid-State Powder Bonding

- What is the principle of rotavap? Efficient, Gentle Solvent Removal for Sensitive Compounds

- What is the meaning of vacuum pyrolysis? Maximize Liquid Fuel Yield from Waste

- Is sputtering a deposition? Discover the PVD Technique for High-Performance Thin Films

- What happens to graphite at high temperatures? Unlock its Extreme Heat Resistance

- Can biomass be used to produce energy? Unlock Renewable Power from Organic Materials

- Why is biomass a better alternative to oil? Unlock a Sustainable, Circular Energy Future

- What gas emissions come from pyrolysis? Turning Waste into Energy and Carbon Sequestration