At its core, plastic pyrolysis is not inherently eco-friendly. While it presents a compelling alternative to sending plastic to landfills, its true environmental impact is conditional. The eco-friendliness of any pyrolysis operation depends entirely on the sophistication of the technology, the management of its byproducts, and the energy sources used to power it.

The central challenge is this: while plastic pyrolysis can convert waste into a resource, it also generates secondary outputs—residue, gas, and wastewater—that can carry their own significant environmental burdens if not properly managed.

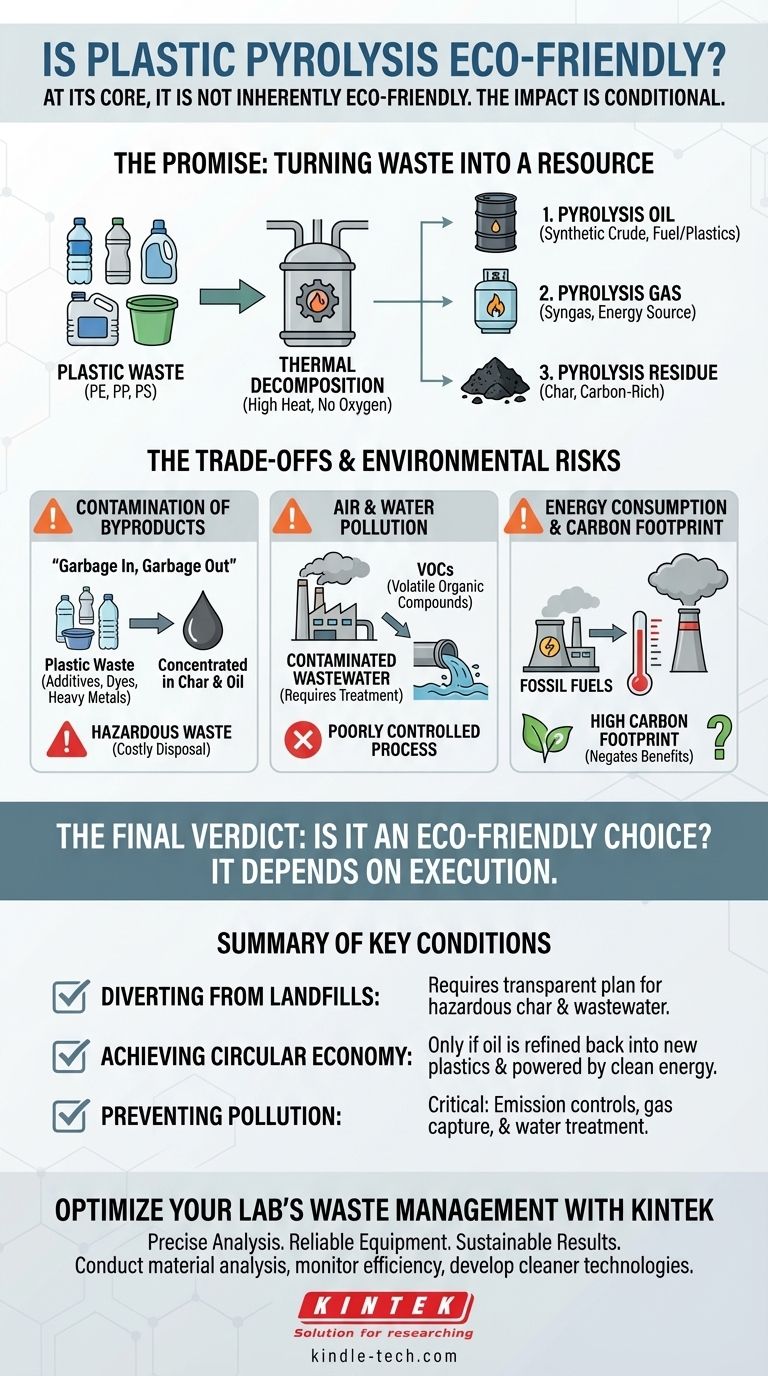

The Promise: Turning Waste into a Resource

Plastic pyrolysis is a form of thermal decomposition, meaning it uses high heat in an oxygen-free environment to break down complex plastic polymers into simpler, more valuable substances.

The Core Process

The goal is to reverse the plastic-making process. By heating plastic waste (like PE, PP, and PS) without oxygen, it avoids combustion and instead breaks the material down into its core components.

The Intended Outputs

This process yields three primary products:

- Pyrolysis Oil: A synthetic crude oil that can be refined into new plastics or used as a fuel.

- Pyrolysis Gas (Syngas): A mixture of combustible gases that can be used to power the pyrolysis facility itself, reducing its reliance on external energy sources.

- Pyrolysis Residue (Char): A solid, carbon-rich byproduct similar to charcoal.

Understanding the Trade-offs and Environmental Risks

The potential benefits are significant, but they come with critical environmental caveats that determine whether a facility is a net positive or a net negative for the environment.

Contamination of Byproducts

The "garbage in, garbage out" principle applies directly here. Contaminants in the original plastic waste—such as additives, dyes, heavy metals, and chlorine—do not simply disappear. They become concentrated in the oil and, most significantly, in the solid char residue. This can render the char a hazardous waste requiring specialized and costly disposal.

Air and Water Pollution

If the process is poorly controlled, it can be a source of pollution. Pyrolysis gas that isn't fully captured and used for energy can release harmful volatile organic compounds (VOCs). Furthermore, any moisture in the plastic waste becomes contaminated wastewater that requires thorough treatment before it can be safely discharged.

Energy Consumption and Carbon Footprint

Running the reactors at the high temperatures required for pyrolysis is an energy-intensive process. If the facility is powered by fossil fuels, it can have a substantial carbon footprint that may negate the benefits of recycling the plastic in the first place. A truly "green" operation must be powered by its own syngas or by renewable energy.

The Challenge of Pyrolysis Oil

The quality of pyrolysis oil can be highly variable and it often requires significant, energy-intensive pre-treatment and refining before it can be used as a feedstock for new plastics. Simply burning it as a low-grade fuel is a less circular, more polluting outcome.

The Final Verdict: Is It an Eco-Friendly Choice?

The eco-friendliness of plastic pyrolysis is a question of execution, not just intention. A state-of-the-art, well-regulated facility is fundamentally different from a low-tech, poorly managed one.

- If your primary focus is diverting plastic from landfills: Pyrolysis is a powerful tool, but you must demand a transparent and environmentally sound plan for managing the resulting hazardous char and wastewater.

- If your primary focus is achieving a circular economy: The technology is only a solution if the pyrolysis oil is successfully refined back into new plastics and the entire operation is powered by clean energy.

- If your primary focus is preventing pollution: The specific plant's emission controls, gas capture efficiency, and wastewater treatment systems are the most critical factors to scrutinize.

Ultimately, the environmental merit of plastic pyrolysis is not inherent in the technology itself, but in the rigor and responsibility with which it is engineered and operated.

Summary Table:

| Aspect | Potential Benefit | Key Environmental Risk |

|---|---|---|

| Waste Diversion | Reduces landfill volume | Contaminated feedstocks create hazardous byproducts |

| Resource Recovery | Produces usable oil and gas | Oil quality is variable; gas can cause air pollution |

| Energy Use | Can be self-powered by syngas | High energy demand increases carbon footprint |

| Byproduct Management | Char can be a carbon source | Char residue often classified as hazardous waste |

Optimize Your Lab's Waste Management with KINTEK

Navigating complex processes like pyrolysis requires precise analysis and reliable equipment. Whether you are researching alternative recycling methods or analyzing the quality of pyrolysis outputs, KINTEK is your partner in achieving accurate and sustainable results.

We specialize in providing high-quality lab equipment and consumables that empower researchers and facilities to:

- Conduct precise material analysis to assess feedstock quality.

- Monitor process efficiency and emissions accurately.

- Develop and validate cleaner pyrolysis technologies.

Let KINTEK provide the tools you need to drive innovation in sustainable waste management. Contact our experts today to find the right solutions for your laboratory's challenges.

Visual Guide

Related Products

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

- Vacuum Dental Porcelain Sintering Furnace

- Laboratory Test Sieves and Sieving Machines

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Laboratory Sterilizer Lab Autoclave Vertical Pressure Steam Sterilizer for Liquid Crystal Display Automatic Type

People Also Ask

- What does a graphite furnace do? Achieve Extreme Heat and Ultra-Sensitive Analysis

- What is the temperature of a graphite furnace? Achieve Extreme Heat Up to 3000°C

- What is the graphite furnace method? Achieve Ultra-High Temperatures with Purity & Speed

- What are the steps in the manufacturing of graphite? From Raw Coke to High-Performance Material

- What is the use of graphite furnace? Achieve Extreme-Temperature Processing for Advanced Materials