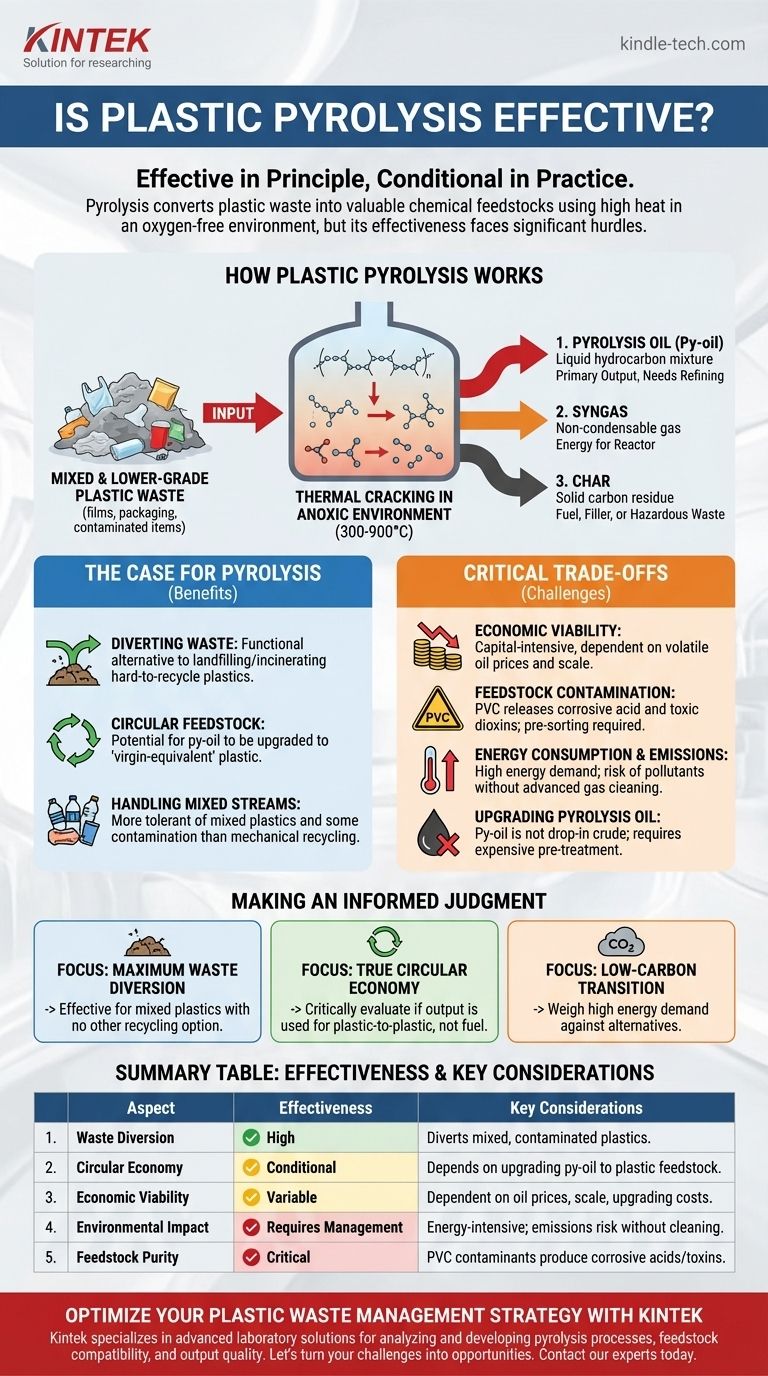

In principle, plastic pyrolysis is an effective technology for converting certain types of plastic waste into valuable chemical feedstocks. It uses high heat in an oxygen-free environment to break down complex plastic polymers into a synthetic oil, gas, and a solid char. However, its real-world effectiveness is highly conditional and faces significant economic, technical, and environmental hurdles that prevent it from being a universal solution to the plastic waste problem.

Pyrolysis holds genuine potential for managing plastic streams that cannot be mechanically recycled. Its ultimate effectiveness, however, is not a simple "yes" or "no" but a complex equation of feedstock purity, energy efficiency, and the immense cost of refining its output into a usable product.

What is Plastic Pyrolysis and How Does It Work?

Plastic pyrolysis is a form of advanced recycling, often categorized under the broader term "chemical recycling." It targets the chemical structure of plastic itself.

The Core Principle: Thermal Cracking

At its heart, pyrolysis is thermal decomposition in an anoxic (oxygen-free) environment. Plastics are long-chain molecules called polymers. When heated to high temperatures (typically 300-900°C) without oxygen, these long chains "crack" and break apart into smaller, less complex molecules, primarily in liquid and gas form.

The Key Inputs: Target Feedstock

Pyrolysis is most often proposed for mixed and lower-grade plastic waste that is unsuitable for traditional mechanical recycling. This includes plastic films, multi-layered packaging, and contaminated items that would otherwise be destined for a landfill or incinerator.

The Primary Outputs: Oil, Gas, and Char

The process yields three main products:

- Pyrolysis Oil (Py-oil): This is the primary output, a liquid hydrocarbon mixture often compared to crude oil. It is the most valuable product but requires significant refining.

- Syngas: A non-condensable gas mixture that is typically captured and used to provide the energy needed to power the pyrolysis reactor itself, reducing external energy needs.

- Char: A solid, carbon-rich residue. Depending on its purity, it may be used as a solid fuel or filler, but it can also contain contaminants that require it to be disposed of as hazardous waste.

Measuring Effectiveness: The Case for Pyrolysis

The technology's effectiveness shines when viewed as a specific tool for a specific problem, rather than a cure-all for plastic waste.

Diverting Waste from Landfills

Pyrolysis provides a functional alternative to landfilling or incinerating hard-to-recycle plastics. This is its most clear-cut benefit, as it can process materials that have no other viable end-of-life pathway, reducing the volume of waste being buried or burned.

Creating a Circular Feedstock

In theory, the py-oil can be upgraded and used as a feedstock in refineries to produce "virgin-equivalent" plastics. This "plastic-to-plastic" loop is the ideal goal of a circular economy, turning old plastic back into new plastic of the same quality.

Handling Mixed and Contaminated Plastics

Unlike mechanical recycling, which demands clean, well-sorted streams of a single plastic type (like PET bottles), pyrolysis is more tolerant of mixed plastic streams (like polypropylene and polyethylene) and some level of contamination.

Understanding the Critical Trade-offs

The theoretical promise of pyrolysis is tempered by significant real-world challenges. Acknowledging these limitations is essential to an objective assessment.

Economic Viability and Scale

Pyrolysis plants are capital-intensive to build and energy-intensive to operate. The economic model often hinges on the market price of crude oil, as py-oil competes with it. If oil prices are low, the process can quickly become unprofitable, making large-scale investment risky.

The Problem of Feedstock Contamination

While pyrolysis is tolerant of some contamination, it is not immune. The presence of PVC (polyvinyl chloride) is a major issue, as it releases chlorine that forms highly corrosive hydrochloric acid and toxic dioxins. This necessitates a pre-sorting step to remove PVC, adding cost and complexity. Other materials like flame retardants and heavy metals can also contaminate the final outputs.

Energy Consumption and Emissions

The process requires a significant energy input to reach and maintain high temperatures. While the syngas produced can offset some of this, the overall energy balance and carbon footprint must be carefully scrutinized. Furthermore, without state-of-the-art gas cleaning systems, there is a risk of releasing hazardous air pollutants.

The Unseen Challenge: Upgrading Pyrolysis Oil

A common misconception is that py-oil is a drop-in replacement for crude oil. It is not. Py-oil is often acidic, unstable, and contains oxygen and other contaminants that must be removed through an intensive and expensive pre-treatment process called "upgrading" or "hydrotreating" before it can be introduced to a conventional refinery. This crucial step is often the most significant economic and technical barrier.

Making an Informed Judgment on Pyrolysis

Your perspective on the effectiveness of pyrolysis should be guided by your primary objective. It is a technology of compromises, not a perfect solution.

- If your primary focus is diverting the maximum amount of plastic from landfills: Pyrolysis can be an effective component of an integrated waste management system, specifically for mixed plastic streams that have no other recycling option.

- If your primary focus is achieving a true circular economy: You must critically evaluate whether the output is genuinely being used for plastic-to-plastic conversion, as plastic-to-fuel applications break the circular loop and have a different environmental profile.

- If your primary focus is a low-carbon energy transition: The high energy demand and carbon footprint of current pyrolysis technologies must be weighed against alternatives, as it is generally more energy-intensive than both virgin production and mechanical recycling.

Ultimately, plastic pyrolysis is a highly promising but challenging technology whose effectiveness is defined not by its theoretical potential, but by its operational efficiency, environmental integrity, and economic viability at scale.

Summary Table:

| Aspect | Effectiveness | Key Considerations |

|---|---|---|

| Waste Diversion | High for non-recyclable plastics | Diverts mixed, contaminated plastics from landfills/incineration |

| Circular Economy | Conditional | Depends on upgrading py-oil to 'virgin-equivalent' plastic feedstock |

| Economic Viability | Variable | Highly dependent on oil prices, plant scale, and upgrading costs |

| Environmental Impact | Requires careful management | Energy-intensive; risk of emissions without proper gas cleaning systems |

| Feedstock Purity | Critical | Contaminants like PVC can produce corrosive acids and toxic byproducts |

Optimize Your Plastic Waste Management Strategy with KINTEK

Navigating the complexities of plastic pyrolysis requires expert knowledge and reliable equipment. KINTEK specializes in providing advanced laboratory solutions for analyzing and developing pyrolysis processes. Whether you are researching feedstock compatibility, optimizing output quality, or scaling up your operations, our precision instruments and consumables are designed to support your goals for a more sustainable future.

Let's turn your plastic waste challenges into opportunities. Contact our experts today to discuss how KINTEK can enhance your pyrolysis research and development.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Mini SS High Pressure Autoclave Reactor for Laboratory Use

- Stainless High Pressure Autoclave Reactor Laboratory Pressure Reactor

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

People Also Ask

- What are the conditions for biomass pyrolysis? Optimize Temperature, Heating Rate & Time

- What is a disadvantage of biomass energy? The Hidden Environmental and Economic Costs

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas