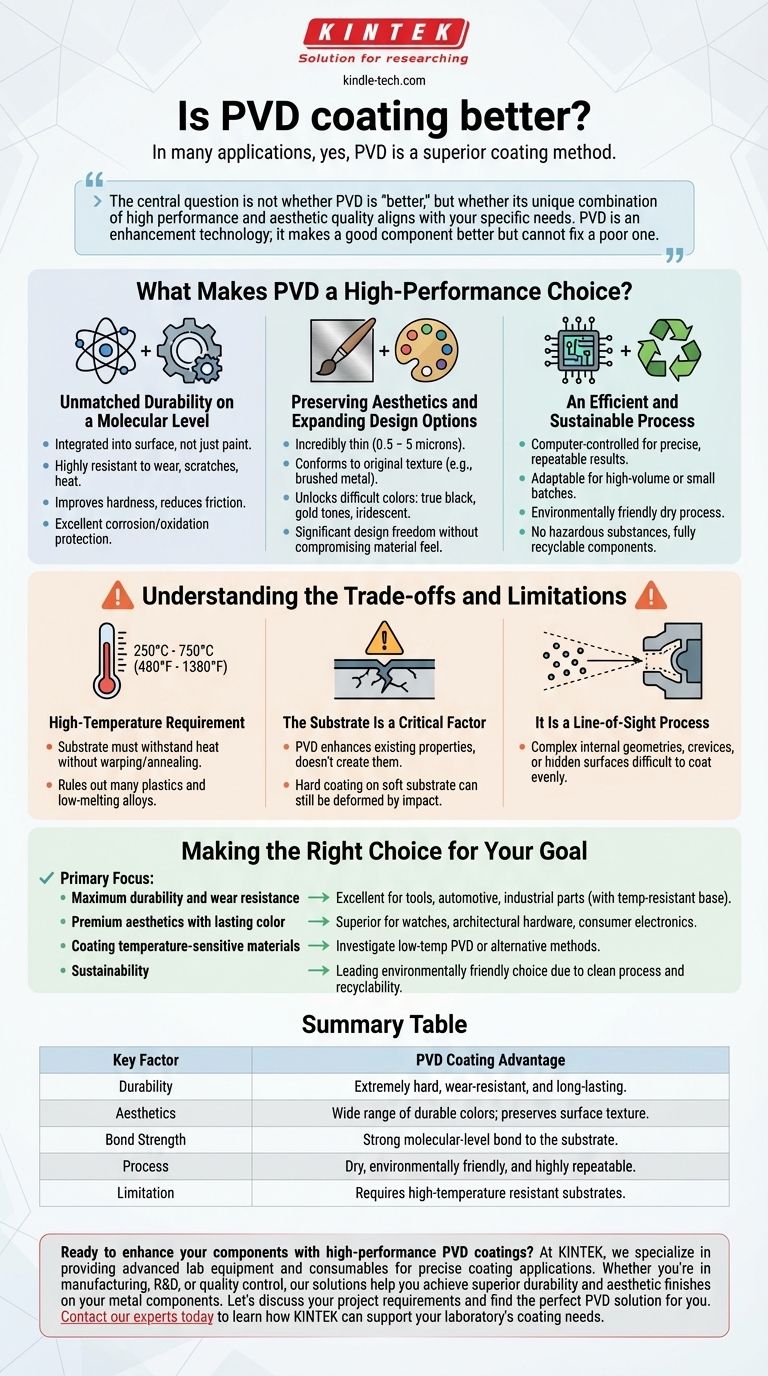

In many applications, yes, Physical Vapor Deposition (PVD) is a superior coating method. It creates an extremely durable, thin-film coating on a molecular level that significantly enhances a component's resistance to wear, corrosion, and friction while offering a wide range of aesthetic finishes. However, its suitability depends entirely on the base material and the specific performance goals of your project.

The central question is not whether PVD is "better," but whether its unique combination of high performance and aesthetic quality aligns with your specific needs. PVD is an enhancement technology; it makes a good component better but cannot fix a poor one.

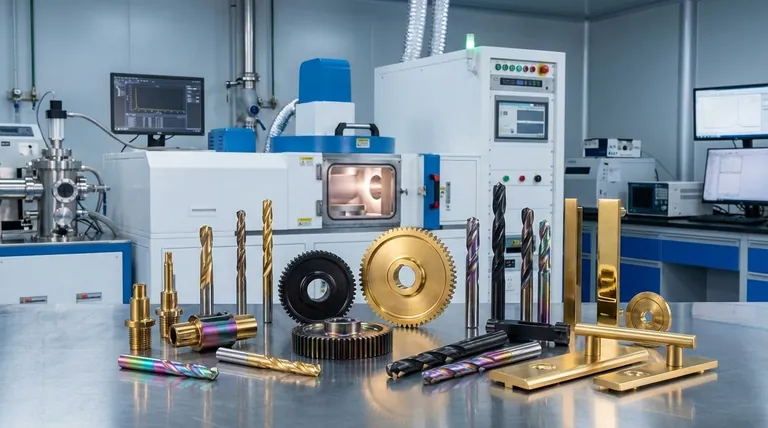

What Makes PVD a High-Performance Choice?

PVD is a process performed in a high-temperature vacuum that physically transfers a coating material onto a substrate, atom by atom. This creates a powerful bond and a finish with distinct advantages.

Unmatched Durability on a Molecular Level

PVD coatings are not simply a layer of paint; they are integrated into the surface of the material. The result is a finish that is highly resistant to wear, scratches, and heat.

This process dramatically improves the hardness of a component, reducing the effects of friction and extending its operational life. It also provides excellent protection against corrosion and oxidation.

Preserving Aesthetics and Expanding Design Options

Because the coating is incredibly thin—typically between 0.5 and 5 microns—it perfectly conforms to the substrate's original surface texture. A brushed metal finish will remain a brushed metal finish.

Furthermore, PVD unlocks new color options that are otherwise difficult to achieve, such as true black, gold tones, and iridescent finishes. This provides significant design freedom without compromising the underlying material's look and feel.

An Efficient and Sustainable Process

Modern PVD machines are computer-controlled, enabling precise and repeatable results that reduce production time and cost. The process is adaptable for both high-volume manufacturing and small, custom batches.

From an environmental standpoint, PVD is a standout. It is a dry process that does not use the hazardous substances common in traditional plating, and the final coated components are fully recyclable.

Understanding the Trade-offs and Limitations

While powerful, PVD is not a universal solution. Understanding its operational requirements and limitations is critical to making an informed decision.

High-Temperature Requirement

The standard PVD process requires high temperatures, often ranging from 250°C to 750°C (480°F to 1380°F). The substrate material must be able to withstand this heat without warping, annealing, or losing its fundamental structural properties.

This constraint immediately rules out many plastics, low-melting-point alloys, and other temperature-sensitive materials for standard PVD application.

The Substrate Is a Critical Factor

PVD enhances existing properties; it does not create them from nothing. The final performance of a PVD-coated part is fundamentally determined by the quality and characteristics of the underlying base material.

Applying a hard PVD coating onto a soft substrate will not make the part dent-proof. The hard coating may resist scratching, but a strong impact will simply deform the soft material underneath it, potentially causing the coating to crack.

It Is a Line-of-Sight Process

In PVD, the coating material travels in a straight line from the source to the substrate. This means complex internal geometries, deep crevices, or hidden surfaces can be difficult or impossible to coat evenly without sophisticated component rotation.

Making the Right Choice for Your Goal

PVD is an exceptional technology when applied correctly. Use these points to guide your decision.

- If your primary focus is maximum durability and wear resistance: PVD is an excellent choice for components like tools, automotive parts, and industrial equipment, provided the base material can tolerate the process temperature.

- If your primary focus is premium aesthetics with lasting color: PVD is a superior method for achieving durable, high-end finishes on items like watches, architectural hardware, and consumer electronics.

- If your primary focus is coating temperature-sensitive materials: You must investigate specialized low-temperature PVD processes or consider alternative coating methods entirely.

- If your primary focus is sustainability: PVD is a leading environmentally friendly choice due to its clean process and the recyclability of the finished product.

Ultimately, knowing these core principles is the key to determining if PVD is the superior solution for your specific application.

Summary Table:

| Key Factor | PVD Coating Advantage |

|---|---|

| Durability | Extremely hard, wear-resistant, and long-lasting. |

| Aesthetics | Wide range of durable colors; preserves surface texture. |

| Bond Strength | Strong molecular-level bond to the substrate. |

| Process | Dry, environmentally friendly, and highly repeatable. |

| Limitation | Requires high-temperature resistant substrates. |

Ready to enhance your components with high-performance PVD coatings?

At KINTEK, we specialize in providing advanced lab equipment and consumables for precise coating applications. Whether you're in manufacturing, R&D, or quality control, our solutions help you achieve superior durability and aesthetic finishes on your metal components.

Let's discuss your project requirements and find the perfect PVD solution for you.

Contact our experts today to learn how KINTEK can support your laboratory's coating needs.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications