Yes, Physical Vapor Deposition (PVD) coatings are highly resistant to corrosion. The process deposits a thin, dense, and non-reactive film at an atomic level, creating a durable barrier between the underlying material and corrosive elements. This advanced finishing technique significantly enhances a product's ability to resist degradation from moisture, salt, and oxidation.

A PVD coating provides an exceptional corrosion-resistant shield for a material's surface. However, its ultimate effectiveness is not determined by the coating alone, but by the complete system—the PVD film working in concert with the corrosion resistance of the underlying substrate material.

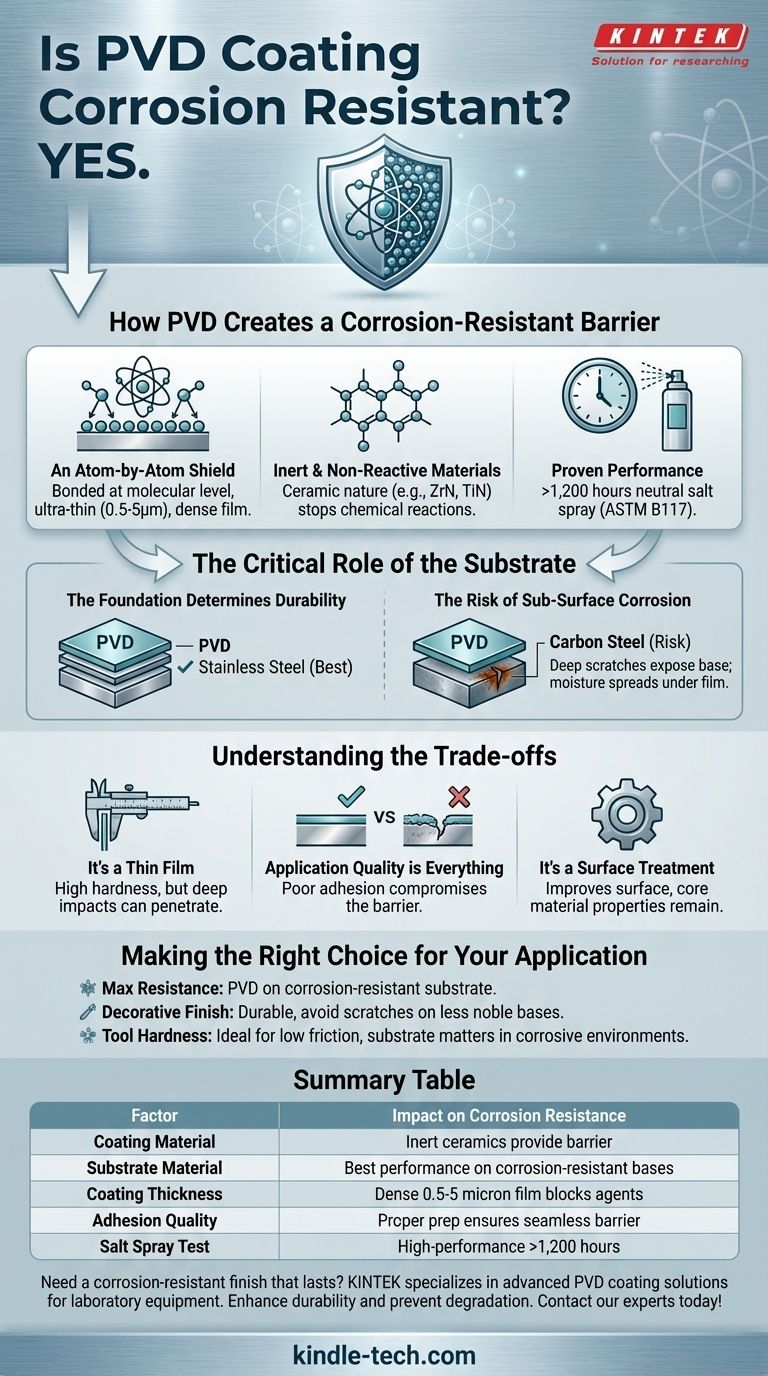

How PVD Creates a Corrosion-Resistant Barrier

An Atom-by-Atom Shield

PVD is not a simple paint or plating; it's a process that bonds a new material to the substrate on a molecular level. This creates an incredibly thin—typically 0.5 to 5 microns—but very dense film.

This density is key to its protective qualities. The film acts as a physical barrier, preventing oxygen and other corrosive agents from reaching the base material.

Inert and Non-Reactive Materials

The materials used for PVD coatings, such as Zirconium Nitride (ZrN) or Titanium Nitride (TiN), are ceramic in nature. These materials are inherently stable and non-reactive.

By applying an inert layer over a more reactive metal, the PVD coating effectively stops the chemical reactions that cause rust and other forms of corrosion.

Proven Performance

Industry-standard tests confirm this high level of resistance. For example, certain PVD coatings like Zirconium Nitride have been shown to surpass 1,200 hours of neutral salt spray testing (ASTM B117).

This level of performance meets or exceeds the requirements for many demanding industrial and architectural applications.

The Critical Role of the Substrate

The Foundation Determines Durability

Think of a PVD coating as high-tech armor. While the armor itself is strong, its performance depends on what lies beneath it.

PVD is most effective when applied to a substrate that already has good corrosion resistance, such as stainless steel. The PVD adds exceptional hardness and wear resistance while amplifying the base material's inherent durability.

The Risk of Sub-Surface Corrosion

If a PVD coating is applied to a material highly prone to rust, like plain carbon steel, any deep scratch or microscopic pinhole in the coating can become a failure point.

Moisture can penetrate the breach and attack the substrate directly. This can cause corrosion to spread underneath the PVD film, eventually causing the coating to flake or peel.

Understanding the Trade-offs

It's a Thin Film

While PVD coatings have very high hardness, they are still extremely thin. A deep gouge or scratch from a significant impact can potentially penetrate the film and expose the substrate.

For most applications involving normal wear and tear, this is not an issue. However, in extremely abrasive environments, the integrity of the film is paramount.

Application Quality is Everything

The corrosion resistance of a PVD coating is highly dependent on its adhesion to the substrate. A properly prepared surface and a well-controlled deposition process are critical.

Poor adhesion can lead to defects in the film, compromising its ability to act as a seamless protective barrier.

It's a Surface Treatment, Not a Change in Bulk Material

PVD improves the surface properties of an object—hardness, low friction, and corrosion resistance—but it does not change the core mechanical properties of the base material itself.

The underlying metal retains its original strength, flexibility, and thermal characteristics.

Making the Right Choice for Your Application

Choosing PVD is about understanding your primary goal and the environment the product will face.

- If your primary focus is maximum corrosion and wear resistance: Apply PVD to an already corrosion-resistant substrate like stainless steel or titanium alloys.

- If your primary focus is adding a decorative finish: PVD is an excellent choice for durability, but the long-term integrity on a less noble base material (like brass) will depend on avoiding deep scratches.

- If your primary focus is improving tool hardness for cutting: PVD is ideal as it provides a hard, low-friction surface, but the substrate choice remains important if the tool will be used in a corrosive environment.

By viewing PVD as one part of a complete material system, you can make an informed decision that ensures long-term performance and durability.

Summary Table:

| Factor | Impact on Corrosion Resistance |

|---|---|

| Coating Material | Inert ceramics like ZrN or TiN provide a non-reactive barrier. |

| Substrate Material | Best performance on corrosion-resistant bases like stainless steel. |

| Coating Thickness | A dense 0.5-5 micron film physically blocks corrosive agents. |

| Adhesion Quality | Proper surface prep ensures a seamless, protective barrier. |

| Salt Spray Test (ASTM B117) | High-performance coatings can exceed 1,200 hours of resistance. |

Need a corrosion-resistant finish that lasts? KINTEK specializes in advanced PVD coating solutions for laboratory equipment and consumables. Our coatings enhance durability, prevent degradation, and ensure long-term performance in demanding environments. Contact our experts today to protect your lab investments with a tailored PVD coating system!

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Electrolytic Electrochemical Cell for Coating Evaluation

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What are diamond coated films? Enhance Materials with Super-Hard, Transparent Layers

- How thick is CVD diamond coating? Balancing Durability and Stress for Optimal Performance

- How long does diamond coating last? Maximize Lifespan with the Right Coating for Your Application

- What is the process of CVD diamond coating? Grow a Superior, Chemically-Bonded Diamond Layer

- Is diamond coating permanent? The Truth About Its Long-Lasting Durability