Yes, a PVD gun finish is exceptionally durable. Physical Vapor Deposition (PVD) is not a paint or a simple coating; it's a high-tech process that molecularly bonds a micro-thin layer of metallic material to the surface of the firearm. This results in a finish that is significantly harder and more resistant to wear, scratches, and corrosion than most traditional firearm finishes.

The core takeaway is that PVD offers superior functional durability—excelling in hardness and wear resistance—but this toughness comes with a trade-off: if the colored finish is damaged by aggressive means, it can be difficult or impossible to repair.

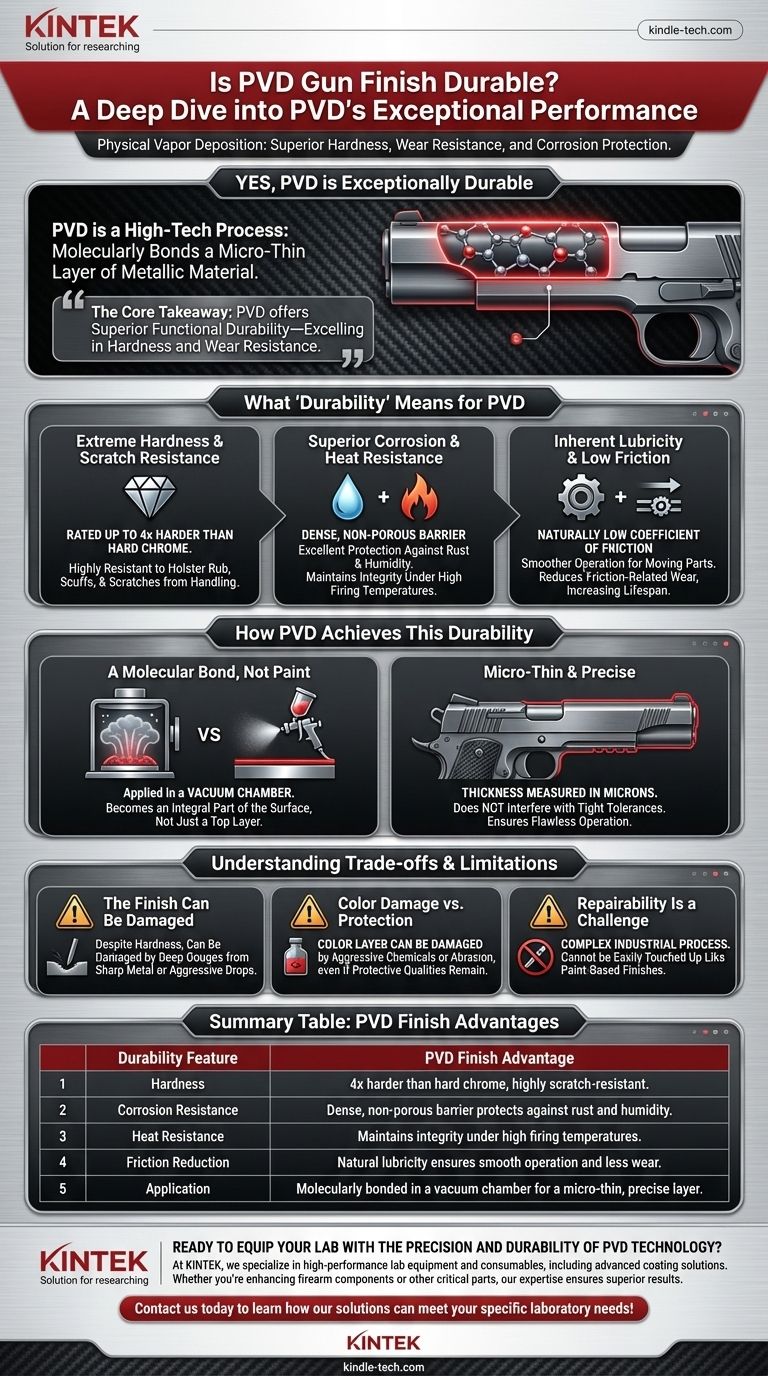

What "Durability" Means for a PVD Finish

The term "durability" can be subjective. For PVD coatings, it refers to specific, measurable advantages in hardness, friction, and resistance to environmental factors.

Extreme Hardness and Scratch Resistance

A PVD finish is extraordinarily hard. Some formulations are rated to be four times harder than hard chrome, which is a benchmark for durable metal coatings.

This extreme hardness means PVD is highly resistant to the most common causes of firearm wear, such as holster rub, minor scuffs, and scratches from handling.

Superior Corrosion and Heat Resistance

The PVD process creates a dense, non-porous barrier on the steel. This provides excellent protection against rust and corrosion caused by humidity, sweat, and harsh environmental conditions.

The coating is also highly resistant to heat, protecting the underlying metal and maintaining its integrity even under the high temperatures generated during rapid firing.

Inherent Lubricity and Low Friction

PVD coatings possess a naturally low coefficient of friction. This property is often referred to as lubricity.

For a firearm, this means that moving parts, like the slide cycling on the frame, operate more smoothly. This reduces friction-related wear on the components themselves, increasing the lifespan of the gun's action.

How PVD Achieves This Durability

The resilience of PVD comes directly from its unique application process, which fundamentally differs from paints or platings.

A Molecular Bond, Not a Layer of Paint

Unlike spray-on finishes like Cerakote, PVD is applied in a vacuum chamber. The coating material is vaporized and then molecularly bonded to the firearm's components.

This means the finish isn't just sitting on top of the metal; it becomes an integral part of its surface at a microscopic level.

Micro-Thin and Precise

The entire PVD layer is incredibly thin, often just a few microns. This is a critical advantage for firearms, as it does not interfere with the tight tolerances of modern gun parts, ensuring flawless operation after application.

Understanding the Trade-offs and Limitations

While PVD is a top-tier finish, it is crucial to understand its limitations. No finish is indestructible.

The Finish Can Be Damaged

Despite its hardness, a PVD finish can be damaged. A deep gouge from a sharp piece of metal or an aggressive drop on a rough surface like concrete can still scratch through the coating.

Color Damage vs. Protection

The most significant caveat is that the color layer can be damaged by aggressive chemical attacks or extreme abrasion, even if the protective qualities remain.

Harsh abrasive cleaners or certain powerful solvents could potentially discolor or mar the aesthetic finish. In these cases, the underlying metal is often still protected, but the visual appeal is compromised.

Repairability Is a Challenge

Because PVD is a complex industrial process, it cannot be easily touched up like a paint-based finish. If a significant scratch or blemish occurs, repairing it is often not a practical option.

Is PVD the Right Choice for Your Firearm?

Deciding on a PVD finish depends entirely on your priorities for your firearm.

- If your primary focus is maximum protection against daily wear and tear: PVD is one of the best choices available, offering unrivaled hardness for resisting holster wear and scuffs.

- If your primary focus is resistance to corrosion and the elements: PVD provides an exceptional, long-lasting barrier against rust, making it ideal for firearms used in harsh environments.

- If your primary focus is having a wide range of colors or easy repairability: You might consider a high-quality ceramic coating, as PVD color options are more limited and cannot be touched up.

Ultimately, choosing PVD is an investment in elite, long-term functional durability for the core components of your firearm.

Summary Table:

| Durability Feature | PVD Finish Advantage |

|---|---|

| Hardness | 4x harder than hard chrome, highly scratch-resistant |

| Corrosion Resistance | Dense, non-porous barrier protects against rust and humidity |

| Heat Resistance | Maintains integrity under high firing temperatures |

| Friction Reduction | Natural lubricity ensures smooth operation and less wear |

| Application | Molecularly bonded in a vacuum chamber for a micro-thin, precise layer |

Ready to equip your lab with the precision and durability of PVD technology? At KINTEK, we specialize in high-performance lab equipment and consumables, including advanced coating solutions for demanding applications. Whether you're enhancing firearm components or other critical parts, our expertise ensures superior results. Contact us today to learn how our solutions can meet your specific laboratory needs!

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- CVD Diamond Domes for Industrial and Scientific Applications

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

- High-Purity Titanium Foil and Sheet for Industrial Applications

- Three-dimensional electromagnetic sieving instrument

People Also Ask

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition