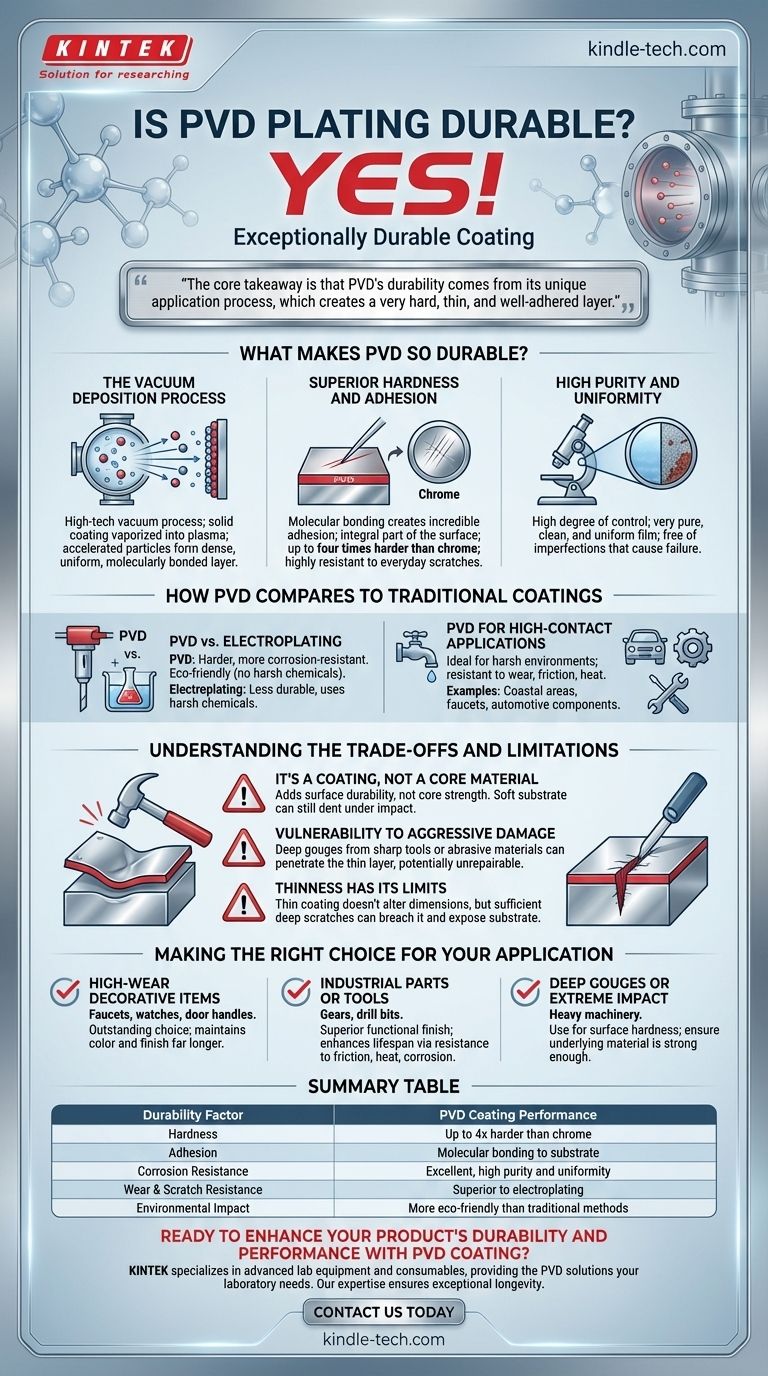

Yes, Physical Vapor Deposition (PVD) is an exceptionally durable coating. It is widely regarded as one of the most resilient surface finishes available today, created through a high-tech vacuum deposition process that molecularly bonds the coating to the substrate. This results in a finish that is significantly harder and more resistant to scratches, corrosion, and wear than most traditional coating methods.

The core takeaway is that PVD's durability comes from its unique application process, which creates a very hard, thin, and well-adhered layer. However, its ultimate effectiveness is a partnership between the coating's hardness and the strength of the underlying material.

What Makes PVD So Durable?

The exceptional durability of PVD isn't an accident; it's a direct result of the highly controlled, scientific process used to apply it.

The Vacuum Deposition Process

PVD is applied within a high-vacuum chamber. The base material is placed inside, and a solid coating material is vaporized into a plasma of atoms or ions. An electric field then accelerates these particles, causing them to strike the base material with such force that they embed into the surface, forming a dense, uniform, and strongly bonded layer.

Superior Hardness and Adhesion

This molecular bonding process creates incredible adhesion. Unlike paint or electroplating, which sit on top of the surface, PVD becomes an integral part of it. The resulting coating is extremely hard—in some cases, up to four times harder than chrome—making it highly resistant to everyday scratches and wear.

High Purity and Uniformity

The PVD process offers a high degree of control over the coating's structure. This results in a very pure, clean, and uniform film that is free of the imperfections that can cause other coatings to fail or corrode over time.

How PVD Compares to Traditional Coatings

PVD stands out when compared directly with more conventional finishing methods, offering significant advantages in performance and longevity.

PVD vs. Electroplating

PVD coatings are generally harder and more corrosion-resistant than those applied by electroplating. The PVD process is also significantly more environmentally friendly, avoiding the harsh chemicals used in traditional electrochemical processes.

PVD for High-Contact Applications

Because of its resistance to wear, friction, and heat, PVD is the ideal choice for projects that are exposed to harsh environments or frequent contact. This includes coastal areas, high-traffic home hardware like faucets, and functional automotive components.

Understanding the Trade-offs and Limitations

While PVD is incredibly robust, no coating is indestructible. Understanding its limitations is key to using it effectively.

It's a Coating, Not a Core Material

PVD adds surface durability, but it does not change the properties of the underlying substrate. A hard PVD coating on a soft metal can still dent if the object suffers a significant impact. The base material provides the structural integrity.

Vulnerability to Aggressive Damage

Although highly resistant to wear, the coating can be damaged by aggressive attacks. A deep gouge from a sharp tool or abrasive material can penetrate the thin layer. In some cases, this type of damage may not be repairable.

Thinness Has Its Limits

The thinness of a PVD coating is one of its benefits, as it doesn't alter a part's dimensions. However, this also means a sufficiently deep scratch can breach the coating and expose the substrate underneath.

Making the Right Choice for Your Application

Selecting the right finish depends entirely on the demands of your project. PVD excels in scenarios where surface integrity is paramount.

- If your primary focus is high-wear decorative items (e.g., faucets, watches, door handles): PVD is an outstanding choice that will maintain its color and finish far longer than traditional options.

- If your primary focus is industrial parts or tools: The coating's resistance to friction, heat, and corrosion makes it a superior functional finish that enhances component lifespan.

- If your project is susceptible to deep gouges or extreme impact: Use PVD for its surface hardness but ensure the underlying material is strong enough to resist deformation.

Ultimately, choosing PVD is an investment in a surface that is engineered for exceptional longevity and performance.

Summary Table:

| Durability Factor | PVD Coating Performance |

|---|---|

| Hardness | Up to 4x harder than chrome |

| Adhesion | Molecular bonding to substrate |

| Corrosion Resistance | Excellent, high purity and uniformity |

| Wear & Scratch Resistance | Superior to electroplating |

| Environmental Impact | More eco-friendly than traditional methods |

Ready to enhance your product's durability and performance with PVD coating? KINTEK specializes in advanced lab equipment and consumables, providing the PVD solutions your laboratory needs for superior surface finishes. Our expertise ensures your components achieve exceptional longevity and resistance to wear, corrosion, and heat. Contact us today to discuss how our PVD technology can benefit your specific application!

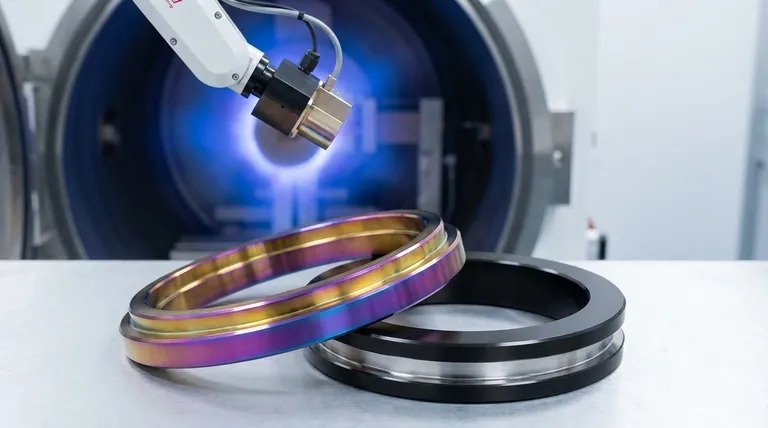

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Customer Made Versatile CVD Tube Furnace Chemical Vapor Deposition Chamber System Equipment

- Cylindrical Resonator MPCVD Machine System Reactor for Microwave Plasma Chemical Vapor Deposition and Lab Diamond Growth

People Also Ask

- How long does diamond coating last? Maximize Lifespan with the Right Coating for Your Application

- What is the process of CVD diamond coating? Grow a Superior, Chemically-Bonded Diamond Layer

- What are diamond coated films? Enhance Materials with Super-Hard, Transparent Layers

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools

- What is diamond coating film? A Thin Layer of Diamond for Extreme Performance