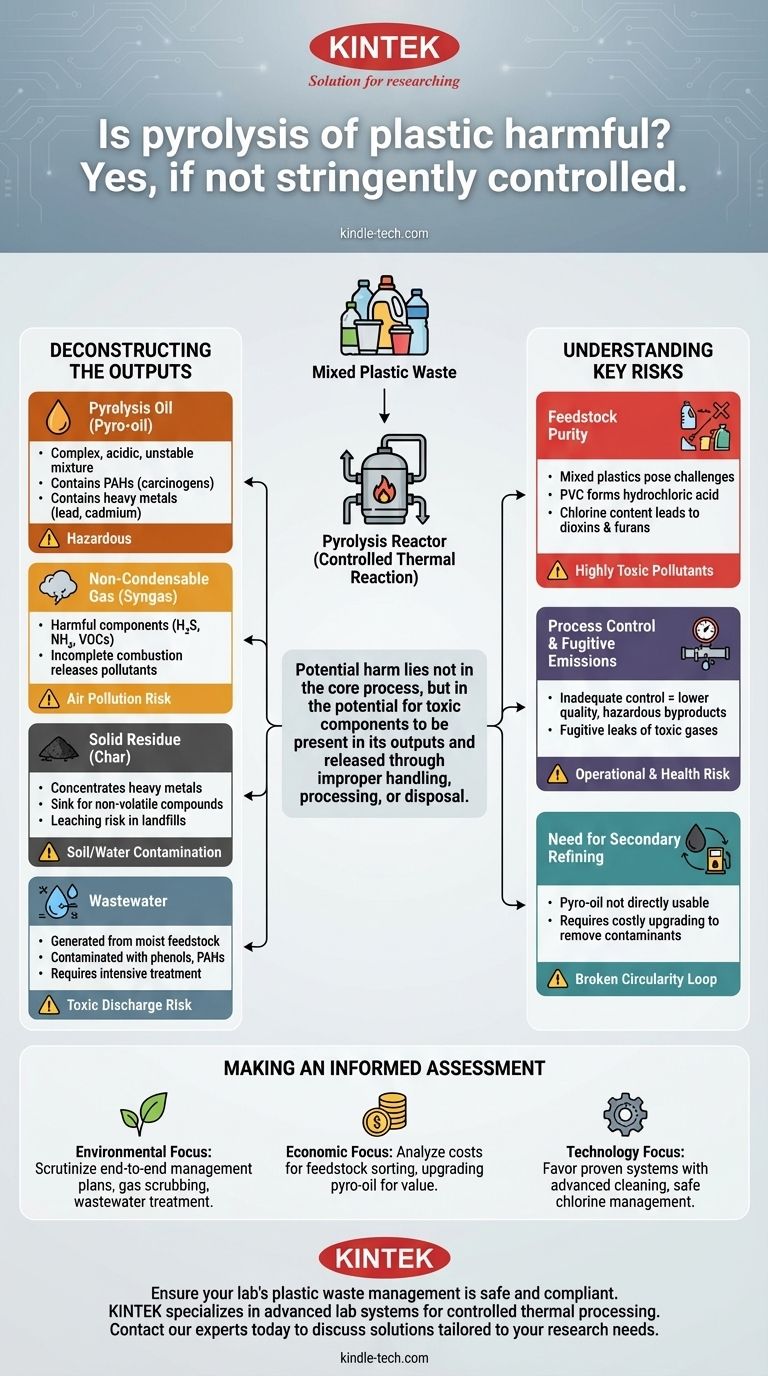

In short, yes, the pyrolysis of plastic can be harmful if not managed with stringent controls. While the process itself is a contained thermal reaction, its outputs—pyrolysis oil, gas, and solid residue—can contain hazardous substances derived from the original plastic waste. The degree of harm is not inherent to the concept of pyrolysis but is directly tied to the quality of the technology, the composition of the plastic feedstock, and the rigor of the operational and environmental controls in place.

The potential harm of plastic pyrolysis lies not in the core process, but in the potential for toxic components to be present in its outputs and released into the environment through improper handling, processing, or disposal.

Deconstructing the Outputs: Where the Harm Originates

The risk associated with plastic pyrolysis is best understood by examining the chemical nature of its three primary products and one secondary waste stream. The original plastic's additives, colorants, and contaminants become concentrated in these outputs.

Pyrolysis Oil (Pyro-oil)

This is the main liquid product, often marketed as a fuel or chemical feedstock. However, it is fundamentally different and more challenging to handle than conventional crude oil.

Pyro-oil is a complex, often acidic, and unstable mixture. It frequently contains Polycyclic Aromatic Hydrocarbons (PAHs), some of which are known carcinogens. It can also contain heavy metals like lead and cadmium that were used as stabilizers or pigments in the original plastic.

Non-Condensable Gas (Syngas)

This is the stream of gases that do not condense into liquid oil during cooling. While it often has enough energy value to help power the pyrolysis process itself, it is not clean-burning natural gas.

This gas can contain harmful components like hydrogen sulfide (H₂S), ammonia (NH₃), and volatile organic compounds (VOCs). If burned incompletely, it can release carbon monoxide and other pollutants. Effective gas "scrubbing" or cleaning systems are essential to prevent air pollution.

Solid Residue (Char)

This black, carbonaceous solid is what remains after the volatile components have been driven off. It is often referred to as "char" or "carbon black."

The primary danger of char is that it acts as a sink for contaminants. Heavy metals and other non-volatile compounds from the plastic feedstock become highly concentrated in this solid residue. If this char is landfilled, these toxins can potentially leach into soil and groundwater.

Wastewater

If the plastic waste feedstock contains moisture, the process will generate wastewater. This isn't just water; it is process water that has come into contact with the various chemical compounds created during pyrolysis.

This water can be contaminated with phenols, PAHs, and other dissolved organic compounds, making it toxic. It requires significant on-site treatment before it can be safely discharged into the environment.

Understanding the Trade-offs and Key Risks

The viability and safety of a plastic pyrolysis facility hinge on managing several critical factors that determine whether it is a net benefit or a source of pollution.

The Problem of Feedstock Purity

The type and cleanliness of the incoming plastic waste are the most significant variables. Mixed plastic streams are a major challenge.

Plastics like Polyvinyl Chloride (PVC) are particularly problematic because their chlorine content can form hydrochloric acid, which corrodes equipment. More dangerously, it can also lead to the formation of dioxins and furans, which are highly persistent and toxic organic pollutants.

Process Control and Fugitive Emissions

Pyrolysis requires precise control over temperature and pressure. Inadequate process control can lead to an inefficient reaction, producing lower-quality oil and a higher concentration of hazardous byproducts.

Furthermore, fugitive emissions—leaks of volatile and toxic gases from seals, pipes, and vents in the facility—are a real operational risk that can harm workers and the local environment.

The Need for Secondary Refining

Pyrolysis oil cannot be used directly as a transportation fuel or easily integrated into a traditional refinery. It must undergo significant, and often costly, secondary processing and upgrading to remove contaminants and stabilize the oil.

Without this secondary refining step, the "circularity" of plastic-to-fuel is a broken loop, as the product has limited practical use.

Making an Informed Assessment

To determine if a specific pyrolysis project is beneficial or harmful, you must move beyond the marketing claims and analyze the technical and operational details.

- If your primary focus is environmental compliance: Scrutinize the facility's plans for end-to-end management of all outputs, including gas scrubbing, wastewater treatment, char testing and disposal, and the upgrading pathway for the pyrolysis oil.

- If your primary focus is economic viability: Analyze the costs associated with feedstock sorting/cleaning and the required upgrading of the pyro-oil, as these steps are critical for creating a valuable product and often underestimated.

- If your primary focus is technology selection: Favor systems with a proven ability to handle feedstock variability, advanced gas cleaning technologies, and a clear, safe management plan for chlorine-containing plastics.

Ultimately, the safety of plastic pyrolysis depends entirely on rigorous engineering, strict operational discipline, and comprehensive regulation.

Summary Table:

| Potential Harm | Source in Pyrolysis Process | Key Risks |

|---|---|---|

| Toxic Pyrolysis Oil | Contains PAHs, heavy metals from plastic additives | Carcinogenic, unstable, requires costly refining |

| Hazardous Syngas | Includes H₂S, NH₃, VOCs from incomplete processing | Air pollution, health risks without proper scrubbing |

| Contaminated Char Residue | Concentrates heavy metals from feedstock | Soil/groundwater pollution if landfilled improperly |

| Polluted Wastewater | Generated from moist plastic, contains phenols/PAHs | Requires intensive treatment before safe discharge |

Ensure your lab's plastic waste management is safe and compliant. The pyrolysis process demands precision and reliable equipment to mitigate environmental hazards. KINTEK specializes in advanced lab systems and consumables for controlled thermal processing, helping laboratories handle complex materials like plastics safely and efficiently.

Contact our experts today to discuss solutions tailored to your pyrolysis research or waste treatment needs.

Visual Guide

Related Products

- Customizable High Pressure Reactors for Advanced Scientific and Industrial Applications

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- High Pressure Laboratory Autoclave Reactor for Hydrothermal Synthesis

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What is the contribution of a hydrothermal reactor to graded pore construction? Precision Templates for TAS

- Why are sealed laboratory reaction vessels necessary in the hydrothermal synthesis of zeolites? Ensure Purity and Yield

- What is the function of a constant temperature hydrothermal reactor? Master Coal Fly Ash Activation

- How does a high-pressure reactor demonstrate its value in accelerated aging? Predict Catalyst Durability Fast

- Why are high-pressure autoclaves essential for preparing bio-based polyamide curing agents from dimeric acid?