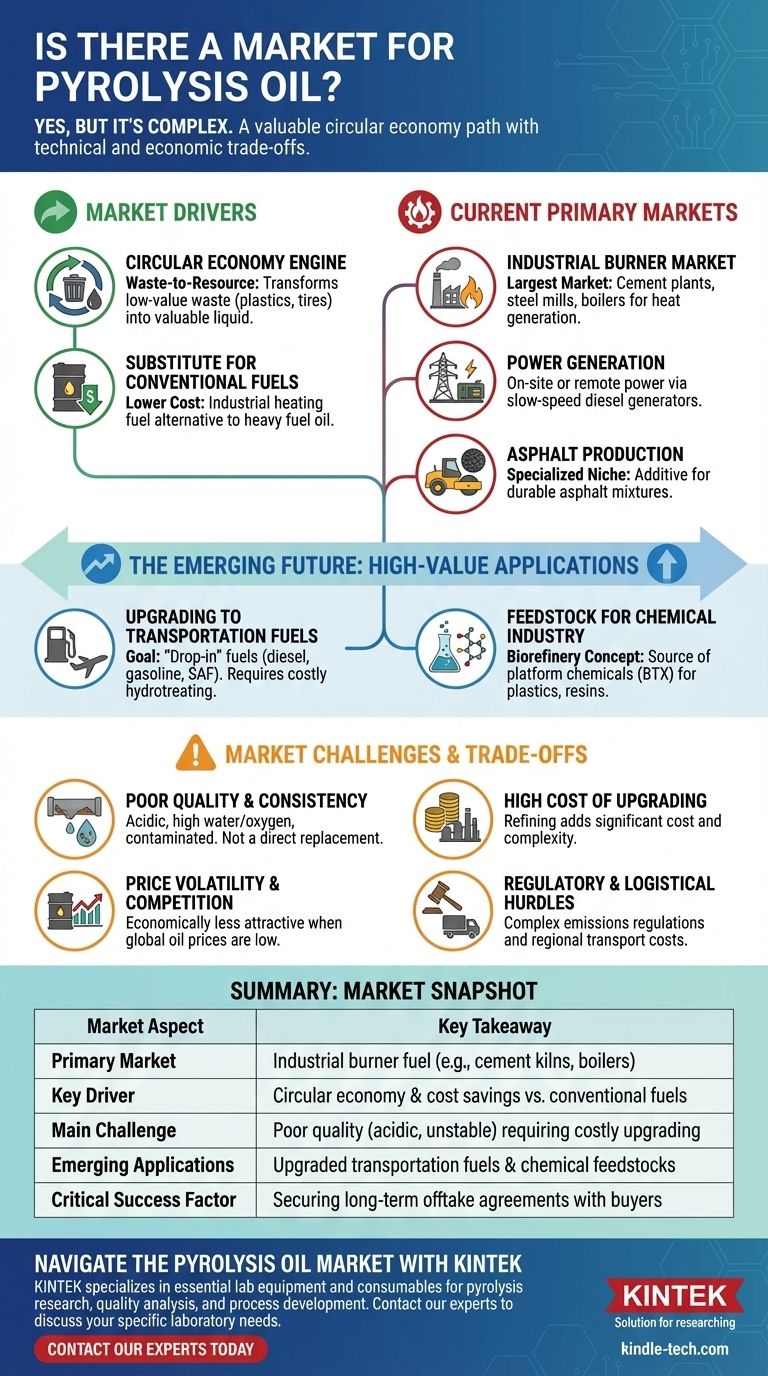

Yes, a definitive market for pyrolysis oil exists, but it is not a simple one. This substance, derived from heating organic waste like plastics, tires, and biomass without oxygen, is primarily sold as a low-grade industrial fuel. It serves as a direct, cheaper replacement for conventional heavy fuel oil or furnace oil in applications like boilers, furnaces, and cement kilns.

The core reality of the pyrolysis oil market is a trade-off. While it offers a valuable path to a circular economy by turning waste into a resource, its commercial viability is constrained by the oil's inherently poor quality, which often requires costly upgrading to compete in higher-value markets.

What is Driving Demand for Pyrolysis Oil?

Pyrolysis oil sits at the intersection of waste management and energy production. Its growing relevance is tied to powerful economic and environmental trends.

The Circular Economy Engine

The fundamental driver is the push for a circular economy. Pyrolysis offers a chemical recycling method to convert low-value waste streams, which would otherwise be landfilled or incinerated, into a valuable liquid resource.

For materials like end-of-life tires and mixed plastics, pyrolysis is one of the few viable technologies that can reclaim energy and material value on a large scale.

A Substitute for Conventional Fuels

In its raw form, pyrolysis oil functions as an industrial heating fuel. Its primary appeal is its lower cost compared to traditional furnace or heavy fuel oil. Industries with high energy consumption see it as a way to reduce operating expenses.

The Primary Markets: Where Pyrolysis Oil is Sold Today

The current market is dominated by applications that can tolerate the oil's lower quality.

The Industrial Burner Market

This is the largest and most established market. Facilities like cement plants, steel mills, thermal power plants, and industrial boilers can burn pyrolysis oil for heat generation. These users are typically equipped to handle different fuel grades and are primarily motivated by cost savings.

Power Generation

Pyrolysis oil can be used in large, slow-speed diesel generators to produce electricity. This is common for on-site power generation at the pyrolysis plant itself or for supplying power in remote locations. However, its use in standard engines often requires modifications or blending with diesel to manage its corrosive nature.

Asphalt Production

When derived from waste tires, pyrolysis oil contains compounds that make it a useful additive in asphalt mixtures. It can improve the binder's properties, making the asphalt more durable. This represents a specialized, higher-value niche compared to burning it as a simple fuel.

The Emerging Future: High-Value Applications

The future growth and profitability of the market lie in upgrading the oil to create more refined products. This is where significant research and investment are focused.

Upgrading to Transportation Fuels

The ultimate goal for many is to upgrade pyrolysis oil into "drop-in" fuels like diesel, gasoline, or sustainable aviation fuel (SAF). This requires a complex and expensive refining process called hydrotreating, which uses hydrogen to remove oxygen, nitrogen, and sulfur.

While technically proven, the high capital cost of upgrading facilities is a major barrier to widespread adoption. Success here would transform pyrolysis oil from a niche fuel into a true competitor with conventional crude oil.

Feedstock for the Chemical Industry

Pyrolysis oil is a complex mixture of valuable chemical compounds. Through fractionation and purification, it can be a source of platform chemicals like benzene, toluene, and xylene (BTX), which are building blocks for plastics, resins, and synthetic fibers. This "biorefinery" or "plastic-to-chemical" concept positions pyrolysis oil as a key enabler of a sustainable chemical industry.

Understanding the Trade-offs and Market Challenges

Success in this market requires a clear understanding of the significant technical and economic hurdles. The oil's quality is the central issue.

The Problem of Quality and Consistency

Raw pyrolysis oil is not a direct replacement for refined fuels. It is characteristically:

- Acidic: Highly corrosive to standard pipes, pumps, and tanks.

- High in Water and Oxygen: This lowers its energy density and makes it unstable, causing it to polymerize and thicken over time.

- Contaminated: It contains fine solid particles (char) and dissolved metals or sulfur (from tires), which can damage equipment and cause harmful emissions if not properly managed.

The High Cost of Upgrading

Solving the quality problem requires investment. Upgrading the oil through processes like filtration, dewatering, and hydrotreating is necessary for high-value applications but adds significant cost and complexity to a project.

Price Volatility and Competition

The price of pyrolysis oil is often benchmarked against the price of conventional heavy fuel oil. When global oil prices are low, the economic advantage of using pyrolysis oil shrinks, making it less attractive to potential buyers.

Regulatory and Logistical Hurdles

Producers must navigate a complex web of environmental regulations governing emissions, transportation, and waste handling. The regional nature of the market means that securing local buyers is critical to minimize transportation costs, which can quickly erode profitability.

How to Apply This to Your Project

Your strategy should be directly aligned with your tolerance for capital risk and your desired position in the value chain.

- If your primary focus is a simple, quick return: Concentrate on selling raw, filtered pyrolysis oil as an industrial burner fuel to local buyers, but be prepared for thin margins and direct competition with furnace oil.

- If your primary focus is maximizing value: Your business plan must include the capital for an upgrading facility to produce either refined fuels or separated chemical feedstocks, targeting a more sophisticated and profitable market.

- If your primary focus is risk mitigation: Secure binding, long-term offtake agreements with creditworthy buyers who have confirmed your oil meets their specific quality requirements before you finalize plant financing.

Success in the pyrolysis oil market is a function of mastering the technical challenges of quality control to unlock its significant economic and environmental potential.

Summary Table:

| Market Aspect | Key Takeaway |

|---|---|

| Primary Market | Industrial burner fuel (e.g., cement kilns, boilers) |

| Key Driver | Circular economy & cost savings vs. conventional fuels |

| Main Challenge | Poor quality (acidic, unstable) requiring costly upgrading |

| Emerging Applications | Upgraded transportation fuels & chemical feedstocks |

| Critical Success Factor | Securing long-term offtake agreements with buyers |

Ready to navigate the pyrolysis oil market for your laboratory or project? KINTEK specializes in providing the essential lab equipment and consumables needed for pyrolysis research, quality analysis, and process development. Whether you are analyzing feedstock, testing oil properties, or scaling up your process, our reliable solutions help you manage the technical challenges and unlock the value of waste-to-energy conversion. Contact our experts today to discuss how we can support your specific laboratory needs and contribute to your project's success.

Visual Guide

Related Products

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Custom PTFE Teflon Parts Manufacturer for Culture Dish and Evaporation Dish

- Custom PTFE Teflon Parts Manufacturer for PTFE Mesh F4 Sieve

People Also Ask

- What are the different types of pyrolysis machines? Choose the Right System for Your Output

- What is the process of biomass fast pyrolysis? Turn Biomass into Bio-Oil in Seconds

- Is pyrolysis viable? A Guide to Economic, Technological, and Environmental Success

- How is energy converted into biomass? Harnessing Nature's Solar Power for Renewable Energy

- What are the advantages of pyrolysis technology? Turn Waste into Profit and Reduce Emissions