Beyond simple cold storage, modern Ultra-Low Temperature (ULT) freezers are sophisticated technological platforms designed for maximum sample security and operational intelligence. Core features include microprocessor-based temperature control, comprehensive alarm systems for any deviation, and onboard data logging via USB. Newer models add remote monitoring, advanced dual-cooling systems, and highly efficient, sustainable refrigerant technologies.

The evolution of ULT freezer technology is driven by a singular goal: to transform a passive cold box into an active, intelligent guardian for your most valuable biological samples. The focus has shifted from merely maintaining temperature to ensuring verifiable integrity, operational efficiency, and proactive failure prevention.

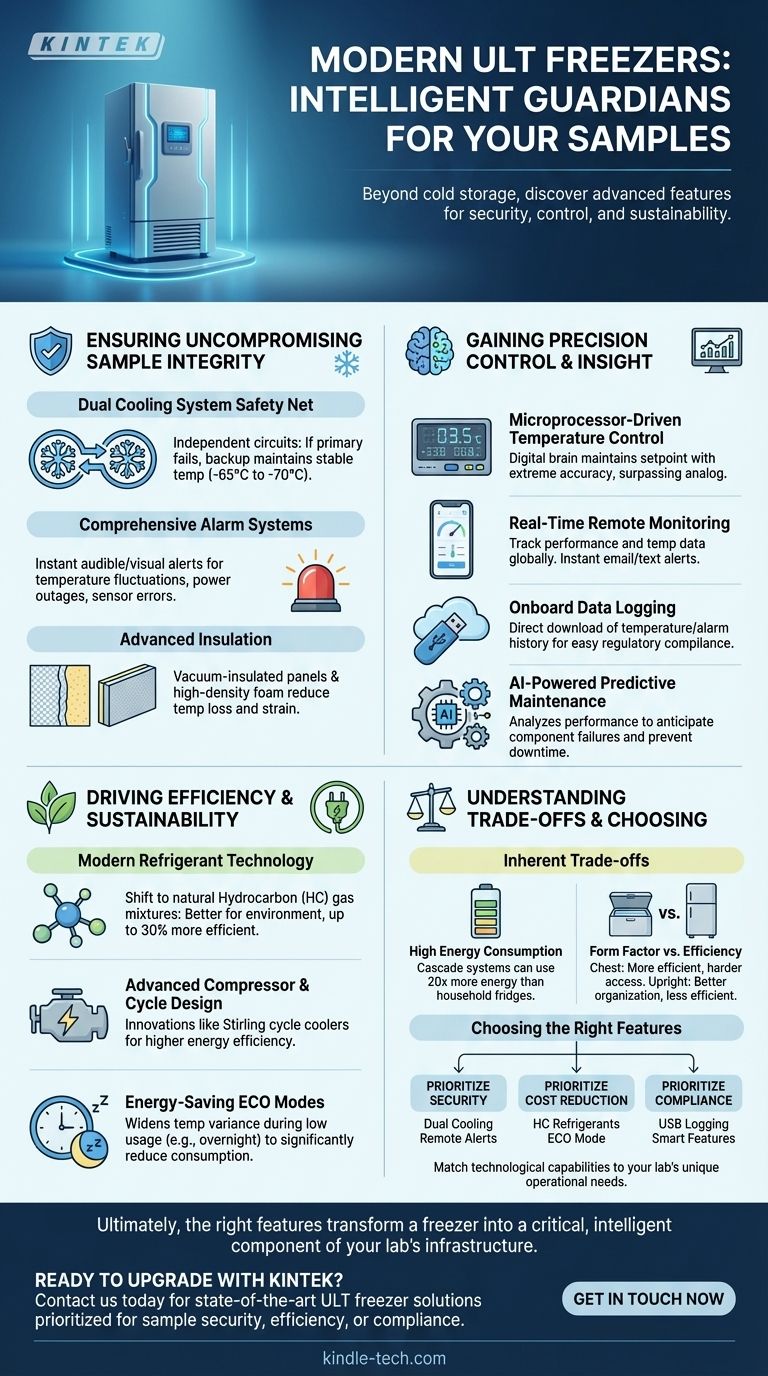

Ensuring Uncompromising Sample Integrity

The primary function of any ULT freezer is to protect its contents. Modern technological advancements are focused on creating multiple layers of security to prevent catastrophic sample loss.

The Dual Cooling System Safety Net

Many high-end ULT freezers now feature a dual refrigeration system. These are two independent cooling circuits. If one primary system fails, the backup system automatically takes over, maintaining a stable temperature (typically around -65°C to -70°C) to protect samples until a repair can be made.

Comprehensive Alarm Systems

Onboard alarms are a critical first line of defense. These systems actively monitor key parameters and provide immediate audible and visual alerts for temperature fluctuations, power outages, and sensor errors. This ensures that lab personnel are notified of a problem the moment it occurs.

Advanced Insulation

While not an electronic feature, advancements in vacuum-insulated panels and high-density foam are crucial. Better insulation reduces temperature loss when the door is opened and lessens the strain on the cooling system, providing a more stable environment and passive protection during a power failure.

Gaining Precision Control and Insight

Modern labs require not just cold, but verifiable, data-driven cold. Features that provide precise control and clear operational insight are now standard.

Microprocessor-Driven Temperature Control

The heart of a modern ULT freezer is its microprocessor controller. This digital brain constantly monitors internal conditions and modulates the cooling system to maintain the temperature setpoint with extreme accuracy, far surpassing older analog thermostats.

Real-Time Remote Monitoring

A growing number of "smart" freezers can connect to your lab's network. This allows managers to track freezer performance and temperature data in real-time from any computer or mobile device. These systems send instant email or text alerts for any deviation, providing peace of mind.

Onboard Data Logging

For regulatory compliance and quality control, integrated data logging is essential. Most units allow for the direct download of temperature and alarm history via a USB port, creating an easy and reliable audit trail without needing external chart recorders.

The Rise of AI and Automation

Emerging technologies include AI-powered predictive maintenance. These systems analyze performance data to anticipate potential component failures before they happen, allowing for scheduled service that prevents costly downtime and sample risk.

Driving Efficiency and Sustainability

ULT freezers are among the most energy-intensive pieces of equipment in a lab. Recent innovations focus heavily on reducing both operating costs and environmental impact.

Modern Refrigerant Technology

There has been a significant shift away from high-impact HFC refrigerants. Modern freezers use natural hydrocarbon (HC) gas mixtures, such as propane and ethane. These are not only better for the environment but can improve cooling efficiency by up to 30%.

Advanced Compressor and Cycle Design

Innovations in compressor technology and refrigeration cycles, such as the specialized Stirling cycle cooler used by some manufacturers, are making ULT freezers more energy-efficient than ever before.

Energy-Saving ECO Modes

Many units now include an ECO mode. This feature allows the freezer to slightly widen its temperature variance during periods of low usage (e.g., overnight), significantly reducing energy consumption without compromising long-term sample viability.

Understanding the Inherent Trade-offs

While advanced features offer clear benefits, they come with considerations that require a balanced decision.

High Energy Consumption

Despite efficiency gains, ULT freezers remain power-hungry, with cascade refrigeration systems consuming up to 20 times more energy than a typical household refrigerator. This is a significant and unavoidable operational cost.

Form Factor vs. Efficiency

The physical design has a direct impact on performance. Chest freezers are generally more energy-efficient because cold air doesn't "fall out" when the lid is opened, but accessing samples can be difficult. Upright freezers offer superior organization and access but are less efficient.

Feature Complexity and Cost

Advanced features like dual cooling systems and smart remote monitoring significantly increase the initial purchase price. A lab must weigh the cost of these features against the monetary and scientific value of the samples being stored.

Choosing the Right Features for Your Lab

Selecting a ULT freezer requires matching its technological capabilities to your specific operational priorities.

- If your primary focus is maximum sample security: Prioritize a model with a true dual refrigeration system and robust remote monitoring alerts.

- If your primary focus is reducing operational cost: Look for units that use hydrocarbon (HC) refrigerants and have a well-implemented, user-configurable ECO mode.

- If your primary focus is streamlined compliance and management: Choose a freezer with reliable onboard USB data logging and intuitive smart features for remote access.

Ultimately, the right technological features transform a freezer from a utility appliance into a critical and intelligent component of your lab's infrastructure.

Summary Table:

| Feature Category | Key Technologies | Primary Benefit |

|---|---|---|

| Sample Integrity | Dual Cooling Systems, Comprehensive Alarms, Advanced Insulation | Prevents catastrophic sample loss, ensures stability |

| Control & Insight | Microprocessor Control, Remote Monitoring, Data Logging, AI Predictive Maintenance | Provides precise temperature control and real-time data for compliance |

| Efficiency & Sustainability | HC Refrigerants, Advanced Compressors, ECO Modes | Reduces energy consumption and environmental impact |

Ready to upgrade your lab's cold storage with intelligent ULT freezers?

KINTEK specializes in providing state-of-the-art lab equipment, including Ultra-Low Temperature freezers equipped with the latest technological advancements. Whether you prioritize maximum sample security, energy efficiency, or streamlined compliance, our solutions are designed to meet your laboratory's unique needs.

Contact us today to discuss how our ULT freezers can protect your valuable samples and optimize your lab's operations. Get in touch with our experts now!

Visual Guide

Related Products

- 58L Precision Laboratory Ultra Low Temperature Upright Freezer for Critical Sample Storage

- 108L Vertical Ultra Low Temperature ULT Freezer

- 508L Advanced Vertical Ultra Low Temperature Freezer for Critical Laboratory Storage

- 408L Advanced Vertical Laboratory Ultra Low Temperature Freezer for Critical Research Material Preservation

- 708L Ultra Low Temperature Freezer High Performance Laboratory Freezer

People Also Ask

- What is the role of an ultra-low temperature (ULT) freezer in the freeze-thaw synthesis of hydrogel nanocomposites?

- How do ultra-low temperature freezers work? Unlocking the Secrets of -86°C Sample Preservation

- How does fast temperature recovery benefit ultra-low freezers? Protect Sample Integrity and Lab Efficiency

- What is the temperature control capability of ultra-low freezers? Precise Stability Down to -86°C

- What are ultra-low temperature freezers designed for? Preserving Your Most Valuable Biological Samples