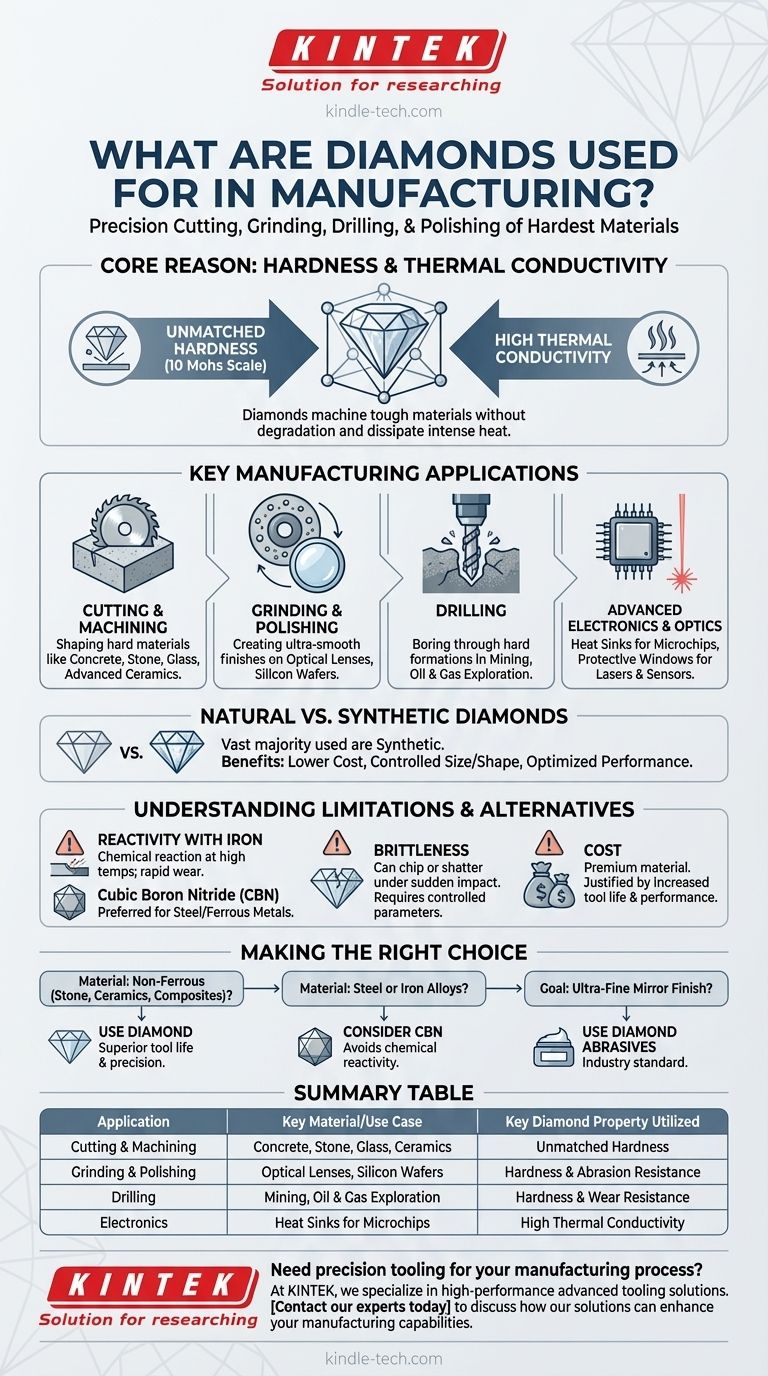

In manufacturing, diamonds are primarily used for cutting, grinding, drilling, and polishing the hardest materials with extreme precision. Their unparalleled hardness allows them to shape everything from concrete and stone in construction to advanced ceramics and composite alloys in aerospace and electronics.

The core reason for using diamonds in industry is their combination of extreme hardness and high thermal conductivity. This allows them to machine other tough materials without quickly degrading, all while dissipating the intense heat generated by friction.

The Properties That Make Diamonds a Superior Tool

The value of an industrial diamond is not in its beauty, but in its unique physical properties. These characteristics make it the ultimate material for many demanding manufacturing processes.

Unmatched Hardness

Diamond is the hardest known natural material, registering a 10 on the Mohs scale of hardness. This means it can scratch or cut virtually any other material.

This property makes diamond-tipped tools indispensable for shaping materials that would quickly wear down tools made of hardened steel or tungsten carbide.

High Thermal Conductivity

In high-friction applications like drilling or grinding, heat is the enemy. It can damage both the tool and the material being worked on.

Diamonds are exceptional thermal conductors, five times better than copper. They rapidly draw heat away from the cutting edge, preventing the tool from overheating and losing its integrity.

Natural vs. Synthetic Diamonds

The vast majority of diamonds used in manufacturing are synthetic. These are created in labs under high-pressure, high-temperature (HPHT) conditions.

Producing diamonds synthetically provides two key advantages: it significantly lowers the cost and allows manufacturers to precisely control the diamond's size, shape, and purity to optimize it for a specific task.

Key Manufacturing Applications

The unique properties of diamond translate directly into a range of critical industrial uses where performance and precision are non-negotiable.

Cutting and Machining

Diamond-edged saws, blades, and cutting tools are essential for shaping hard, brittle, or abrasive materials. This includes cutting concrete, asphalt, stone, brick, glass, and advanced ceramics.

Grinding and Polishing

Tiny diamond particles are embedded into grinding wheels or mixed into slurries and pastes. These are used to create ultra-smooth, high-precision finishes on hard materials like optical lenses, silicon wafers, and engine components.

Drilling

In industries like mining, oil and gas exploration, and geotechnical engineering, drill bits are impregnated with diamonds. These bits can bore through miles of hard rock formations that would be impenetrable with conventional tools.

Advanced Electronics and Optics

Diamonds are used as heat sinks in high-power electronic devices and microchips to efficiently dissipate waste heat. Their durability and transparency also make them ideal for creating protective windows for lasers and sensors operating in harsh environments.

Understanding the Limitations

Despite their advantages, diamonds are not the perfect tool for every situation. Understanding their limitations is key to using them effectively.

Reactivity with Iron

At the high temperatures generated during machining, the carbon in a diamond tool can have a chemical reaction with iron. This causes rapid tool wear.

For this reason, other superhard materials like Cubic Boron Nitride (CBN) are often preferred for high-speed machining of steel and other ferrous metals.

Brittleness

While diamond is incredibly hard, it is also brittle. It can chip or shatter if subjected to a sharp, sudden impact.

Tool design and machining parameters must be carefully controlled to leverage its hardness without causing catastrophic failure due to its brittleness.

Cost

Even though synthetic diamonds are far cheaper than gem-quality ones, they are still a premium material compared to other common abrasives like silicon carbide or aluminum oxide. Their use is typically justified by increased tool life and superior performance.

Making the Right Choice for Your Application

The decision to use diamond tooling depends entirely on the material you are working with and the outcome you need to achieve.

- If your primary focus is machining non-ferrous materials like stone, ceramics, or carbon composites: Diamond is the definitive and superior choice for tool life and precision.

- If your primary focus is high-speed cutting of steel or iron alloys: Consider Cubic Boron Nitride (CBN) as a more effective alternative to avoid diamond's chemical reactivity.

- If your primary focus is achieving an ultra-fine, mirror-like finish on a hard material: Diamond abrasives and polishing compounds are the industry standard.

Ultimately, selecting the right superhard material is about matching the tool's properties to the unique demands of the job.

Summary Table:

| Application | Key Material/Use Case | Key Diamond Property Utilized |

|---|---|---|

| Cutting & Machining | Concrete, Stone, Glass, Ceramics | Unmatched Hardness |

| Grinding & Polishing | Optical Lenses, Silicon Wafers | Hardness & Abrasion Resistance |

| Drilling | Mining, Oil & Gas Exploration | Hardness & Wear Resistance |

| Electronics | Heat Sinks for Microchips | High Thermal Conductivity |

Need precision tooling for your manufacturing process?

At KINTEK, we specialize in high-performance lab equipment and consumables, including advanced tooling solutions. Whether you're working with advanced ceramics, composites, or other hard materials, our expertise can help you select the right superabrasive for maximum efficiency and tool life.

Contact our experts today to discuss how our solutions can enhance your manufacturing capabilities.

Visual Guide

Related Products

- CVD Diamond for Thermal Management Applications

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Precision Wire Saw Laboratory Cutting Machine with 800mm x 800mm Workbench for Diamond Single Wire Circular Small Cutting

- CVD Diamond Domes for Industrial and Scientific Applications

- Custom CVD Diamond Coating for Lab Applications

People Also Ask

- What are the alternatives to rotavap? Find the Right Solvent Removal Method for Your Lab

- What is the advantage of an e-beam evaporator over a filament evaporator? Achieve Higher Purity & Precision

- How does graphite react to heat? Unlocking Its Unique High-Temperature Strengths

- What is the maintenance of laboratory equipment? Ensure Data Integrity and Extend Equipment Lifespan

- How long does it take to heat treat steel? From Hours to Days, Depending on Your Goal

- How long does fast pyrolysis take? Achieve High Bio-Oil Yields in Under 2 Seconds

- What is the function of a magnetic stirrer during the alkaline etching of nano-silicon carbide? Essential Mixing Guide

- What is the advantage of rotary pump over centrifugal pump? Precision Handling for High-Viscosity Fluids