A machine that makes pills is most commonly called a tablet press. While "pill press" is a widely understood term, in professional, industrial, and pharmaceutical contexts, the more precise names are tablet compression machine or tablet press. These machines are engineered to compress powder or granular materials into uniform solid tablets of a specific size, shape, and weight.

The key takeaway is that "tablet press" is the standard industry term. The critical distinction for anyone in the field is understanding the two primary types: the simple single-punch press used for development and the high-speed rotary press used for mass production.

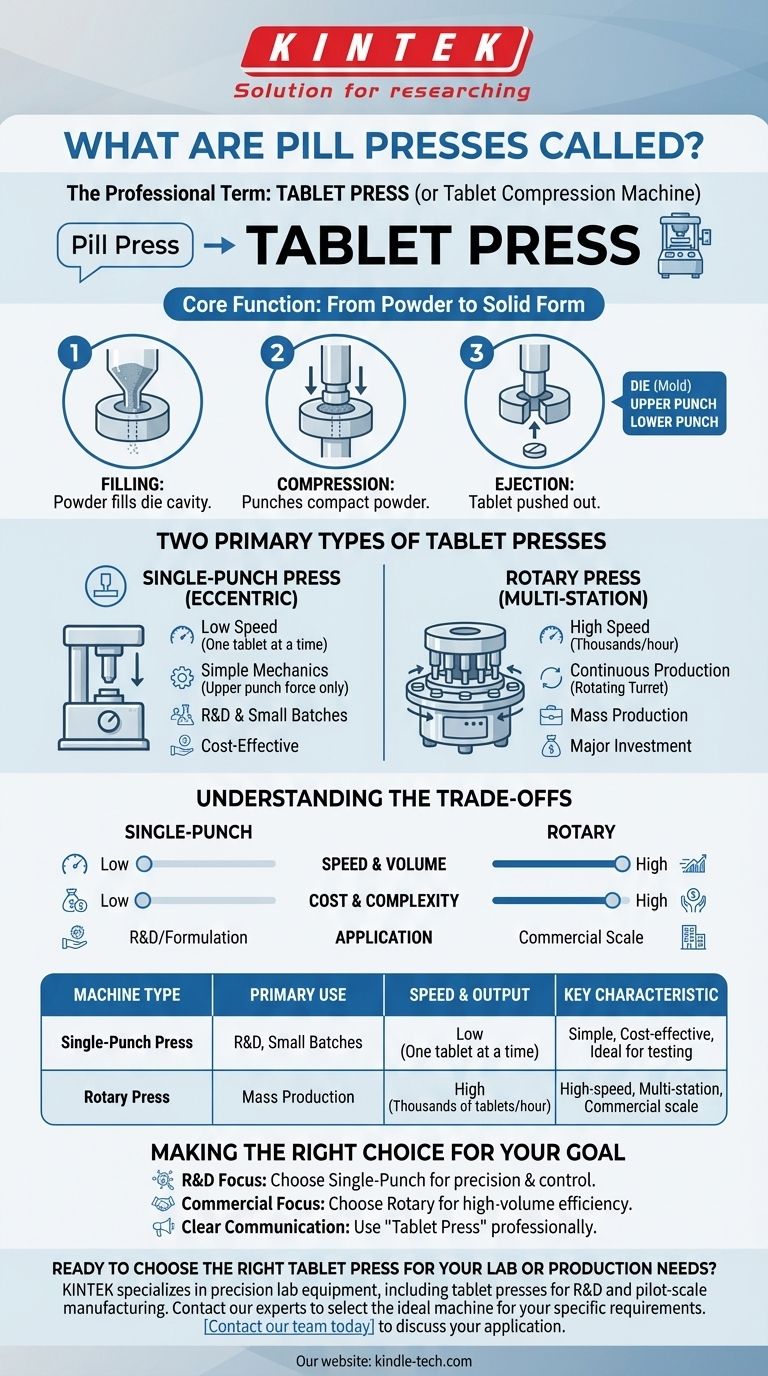

The Core Function: From Powder to Solid Form

At its heart, a tablet press is a mechanical device that applies immense pressure to a specific volume of powder inside a mold. This process, known as compression, creates a solid, durable tablet.

How Compression Works

The process involves three fundamental stages:

- Filling: The die cavity (the mold that defines the tablet's shape) is filled with a precise amount of granulated powder.

- Compression: An upper and lower punch are brought together, compacting the powder within the die under extreme force.

- Ejection: The upper punch retracts, and the lower punch pushes the finished tablet up and out of the die cavity.

Key Components of the Process

Understanding the terminology for the core components is crucial.

- Die: This is the mold that dictates the diameter and shape of the final tablet.

- Upper Punch: This component descends into the die to compress the powder from the top.

- Lower Punch: This component sits within the die, contains the powder from the bottom, and later rises to eject the finished tablet.

The Two Primary Types of Tablet Presses

The most important distinction in tablet compression technology is between single-punch and rotary designs. Their mechanics and applications are entirely different.

The Single-Punch (or Eccentric) Press

A single-punch press has one station, meaning a single die and one pair of upper and lower punches.

The compression force is applied only by the upper punch, making it a simpler and slower mechanical process. These machines are typically smaller and operate at a much lower speed.

The Rotary (or Multi-Station) Press

A rotary press is the standard for industrial manufacturing. It features a large, rotating turret that holds numerous stations of dies and punches.

As the turret spins, the dies are filled with powder, and the punches pass through compression rollers that apply force from both above and below. This design allows for continuous, high-speed production, with modern machines capable of producing hundreds of thousands of tablets per hour.

Understanding the Trade-offs

Choosing between these machine types involves a clear trade-off between speed, scale, and purpose. There is no single "best" type; they are simply tools for different jobs.

Speed and Volume

The most obvious difference is output. A single-punch press is designed for slow, deliberate work, producing one tablet at a time.

A rotary press is built for massive scale, with its multiple stations enabling continuous, high-volume manufacturing that is essential for commercial production.

Cost and Complexity

Single-punch presses are mechanically simpler, smaller, and therefore significantly less expensive. They are common in laboratory settings.

Rotary presses are large, complex, and represent a major capital investment. They require specialized operators and maintenance due to their intricate systems and high-speed operation.

Application and Flexibility

A single-punch press is ideal for research and development (R&D). It allows formulators to test new powder blends, check tablet hardness, and create small batches for analysis without wasting large amounts of material.

A rotary press is built for consistency and efficiency in mass production. Once a formula is perfected, it is moved to a rotary press to be manufactured at scale.

Making the Right Choice for Your Goal

Your objective determines which terminology and technology are relevant.

- If your primary focus is research and development: A single-punch press provides the necessary control, precision, and small-batch capability for testing formulations.

- If your primary focus is high-volume commercial manufacturing: A rotary tablet press is the only viable option for achieving the speed and efficiency required for market supply.

- If your primary focus is accurate communication: Use the term "tablet press" or "tablet compression machine" in any professional or technical discussion.

By understanding the correct terminology and the fundamental differences in machine design, you can accurately navigate the landscape of pharmaceutical and industrial manufacturing.

Summary Table:

| Machine Type | Primary Use | Speed & Output | Key Characteristic |

|---|---|---|---|

| Single-Punch Press | R&D, Small Batches | Low (one tablet at a time) | Simple, cost-effective, ideal for formulation testing |

| Rotary Press | Mass Production | High (thousands of tablets/hour) | High-speed, multi-station, essential for commercial scale |

Ready to choose the right tablet press for your lab or production needs?

KINTEK specializes in precision lab equipment, including tablet presses for both R&D and pilot-scale manufacturing. Whether you need a reliable single-punch press for formulation development or are scaling up to a rotary system, our experts can help you select the ideal machine for your specific materials and throughput requirements.

Contact our team today to discuss your application and get a personalized recommendation!

Visual Guide

Related Products

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Single Punch Electric Tablet Press Machine TDP Tablet Punching Machine

- Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Single Punch Manual Tablet Press Machine TDP Tablet Punching Machine

People Also Ask

- What are pill presses used for? Transforming Powders into Precise Tablets for Medicine, Supplements, and More

- What is the function of a tablet press? Transforming Powder into Precise, Uniform Tablets

- What is the working principle of pelletizing machine? Transform Powders into Dense, Uniform Pellets

- What are the advantages of a rotary tablet machine? Unlock High-Speed, Precise Tablet Production

- What is a tablet punch? The Precision Tool Shaping Your Tablet Manufacturing

- What is the function of rotary tablet press? High-Speed, High-Volume Tablet Production

- What is tablet pressing in pharmaceutical industry? The Core Process for Producing Solid Oral Dosage Forms

- What is a single punch tablet machine? The Essential Tool for Lab-Scale Tablet R&D