In short, Silicon Carbide (SiC) components are a new class of semiconductor devices built from a compound of silicon and carbon. Unlike traditional silicon (Si) devices, SiC's unique material properties allow it to handle significantly higher voltages, frequencies, and temperatures, making it a transformative technology for modern power electronics.

The shift from traditional silicon to Silicon Carbide is not just an incremental upgrade. It represents a fundamental change that enables the design of power systems that are dramatically smaller, faster, and more efficient.

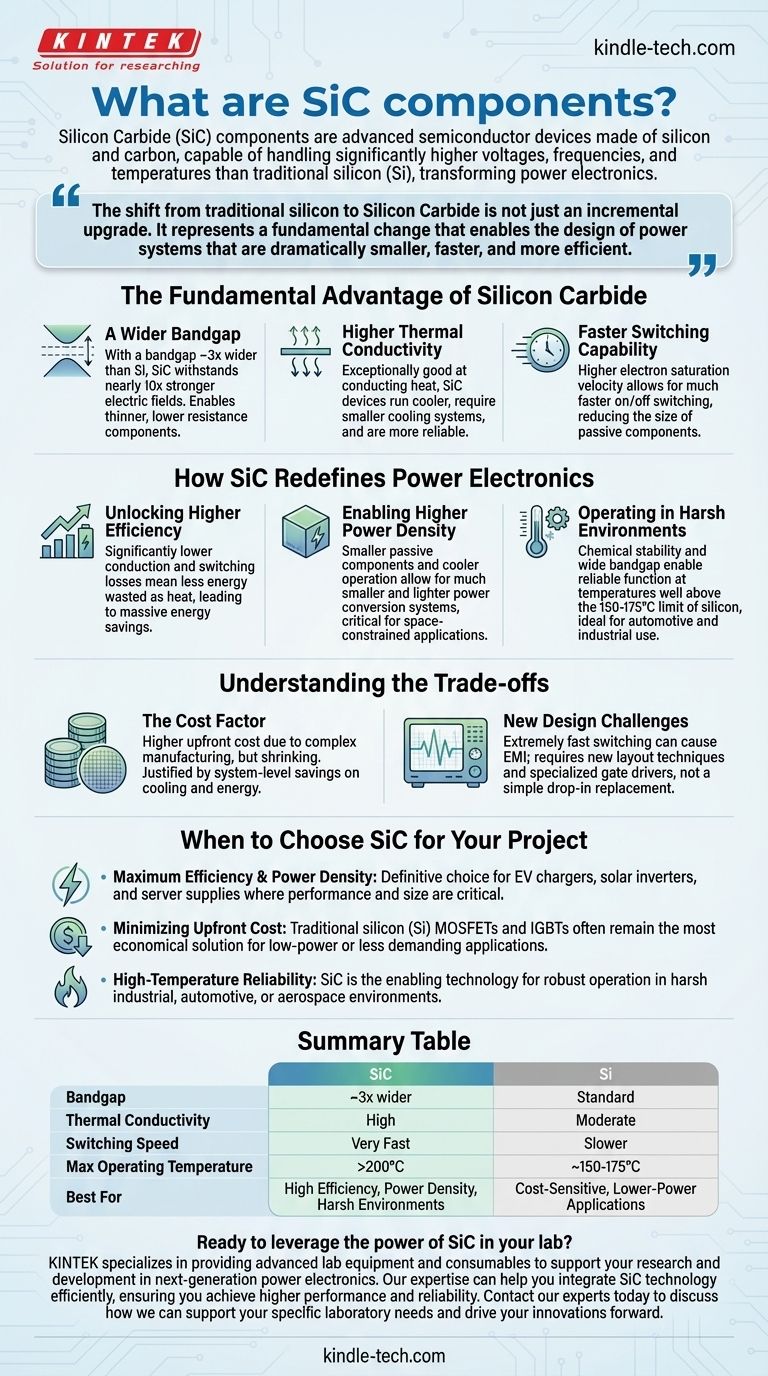

The Fundamental Advantage of Silicon Carbide

The superiority of SiC over conventional silicon isn't magic; it stems directly from its core material physics. These properties solve the key limitations that have constrained power system design for decades.

A Wider Bandgap

A material's bandgap determines the energy required to excite an electron into a conductive state. SiC has a bandgap roughly three times wider than silicon.

This wider bandgap allows SiC devices to withstand electric fields nearly ten times stronger before breaking down. This means a SiC component can block the same voltage as a silicon component in a fraction of the thickness, drastically reducing resistance and energy loss.

Higher Thermal Conductivity

SiC is exceptionally good at conducting heat, pulling it away from the active parts of the chip far more effectively than silicon can.

This superior thermal management means SiC devices run cooler, require smaller and less expensive cooling systems (like heatsinks), and are inherently more reliable in high-power conditions.

Faster Switching Capability

SiC also possesses a higher electron saturation velocity, which allows its devices to switch on and off much more quickly than silicon-based equivalents like IGBTs.

This high-speed switching is the key to reducing the size of surrounding passive components, such as inductors and capacitors, which is a primary driver of higher power density.

How SiC Redefines Power Electronics

These material advantages translate directly into tangible, system-level benefits that are revolutionizing industries from electric vehicles to renewable energy.

Unlocking Higher Efficiency

SiC devices have significantly lower conduction losses (resistance when on) and switching losses (energy lost during on/off transitions).

Less energy is wasted as heat, meaning more power is delivered to the load. An efficiency gain of even a few percentage points can lead to massive energy savings and reduced operating costs over a system's lifetime.

Enabling Higher Power Density

Because SiC devices are more efficient, run cooler, and enable the use of smaller passive components, the entire power conversion system can be made much smaller and lighter.

This is a critical advantage in applications where space and weight are at a premium, such as in electric vehicles, satellites, or portable power systems.

Operating in Harsh Environments

The inherent chemical stability and wide bandgap of SiC allow it to function reliably at temperatures well above the 150-175°C limit of silicon.

This makes SiC the ideal choice for demanding applications in the automotive, aerospace, industrial, and down-hole drilling sectors where high ambient temperatures are unavoidable.

Understanding the Trade-offs

While SiC offers compelling advantages, it is not a universal replacement for silicon. Acknowledging the trade-offs is key to making an informed design choice.

The Cost Factor

Manufacturing high-quality SiC crystal wafers is a more complex and expensive process than that for silicon. This translates to a higher upfront cost for SiC MOSFETs and diodes compared to their silicon counterparts.

However, this cost difference is steadily shrinking, and the higher component cost can often be justified by system-level savings on cooling, magnetics, and energy consumption.

New Design Challenges

The extremely fast switching speeds of SiC, while a benefit, can also create design challenges like increased electromagnetic interference (EMI).

Engineers must adopt new layout techniques and use specialized gate drivers designed to control SiC devices properly, as a simple "drop-in replacement" for a silicon part is rarely feasible.

When to Choose SiC for Your Project

The decision to use SiC depends entirely on your project's primary objectives.

- If your primary focus is maximum efficiency and power density: SiC is the definitive choice for applications like EV chargers, solar inverters, and server power supplies where performance and size are critical.

- If your primary focus is minimizing upfront component cost: For low-power or less demanding applications, traditional silicon (Si) MOSFETs and IGBTs often remain the most economical solution.

- If your primary focus is high-temperature reliability: SiC is the enabling technology required for robust operation in harsh industrial, automotive, or aerospace environments.

Choosing the right semiconductor technology is about deliberately matching the material's strengths to your specific engineering goals.

Summary Table:

| Feature | Silicon Carbide (SiC) | Traditional Silicon (Si) |

|---|---|---|

| Bandgap | ~3x wider | Standard |

| Thermal Conductivity | High | Moderate |

| Switching Speed | Very Fast | Slower |

| Max Operating Temperature | >200°C | ~150-175°C |

| Best For | High Efficiency, Power Density, Harsh Environments | Cost-Sensitive, Lower-Power Applications |

Ready to leverage the power of SiC in your lab? KINTEK specializes in providing advanced lab equipment and consumables to support your research and development in next-generation power electronics. Our expertise can help you integrate SiC technology efficiently, ensuring you achieve higher performance and reliability. Contact our experts today to discuss how we can support your specific laboratory needs and drive your innovations forward.

Visual Guide

Related Products

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Infrared High Resistance Single Crystal Silicon Lens

- RRDE rotating disk (ring disk) electrode / compatible with PINE, Japanese ALS, Swiss Metrohm glassy carbon platinum

- Glassy Carbon Electrochemical Electrode

People Also Ask

- How does an armored K-type thermocouple ensure the repeatability of experimental results? Achieve Precision in Nitriding

- How are heating elements made? The Science of Self-Regulating PTC Ceramic Heaters

- Which metal works best as a heating element? Choose the Right Alloy for Your Temperature & Environment

- How does precise temperature control affect FeCoCrNiMnTiC high-entropy alloys? Master Microstructural Evolution

- What is the melting point of tungsten in a vacuum? The Real Limit is Sublimation, Not Melting

- How does a heating element heat up? The Science of Joule Heating Explained

- What is the temperature limit of silicon carbide? Maximize Performance from 1600°C to 2500°C

- What is the temperature range of a MoSi2 heating element? Unlock 1900°C Performance for Your Lab